Equipment for processing abrasive slurry water-jet microporous nozzle internal runner and method for detecting and controlling real-time flux

A technology of abrasive slurry jet and processing equipment, which is applied in the direction of metal processing equipment, relative volume flow measurement, abrasive jet machine tools, etc. It can solve the problems of difficult to stabilize pressure, easy fluctuation of system pressure, large measurement error, etc., and achieve high grinding efficiency , Improve the flow rate coefficient, the effect of strong grinding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

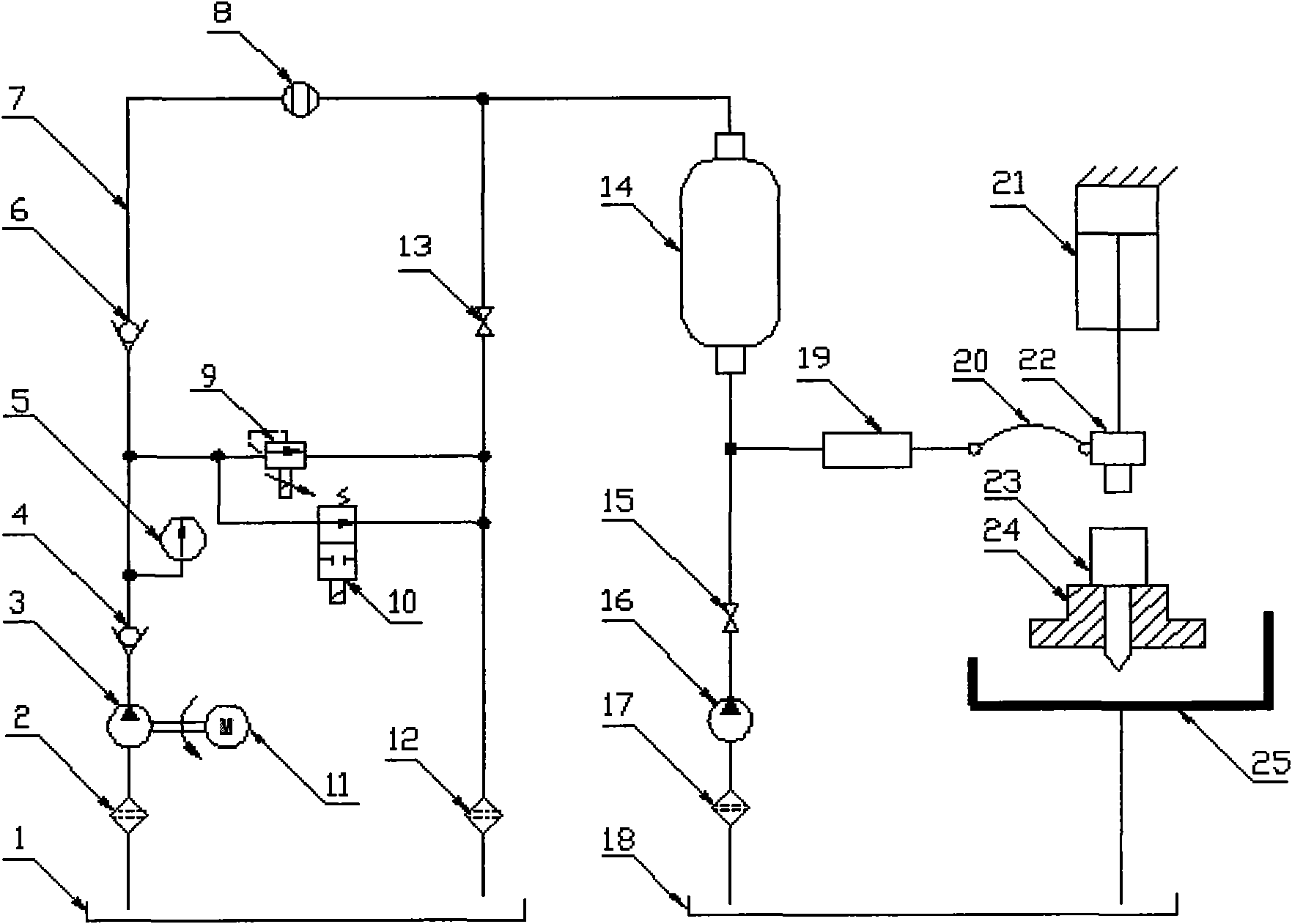

[0025] A preferred embodiment of the present invention is described in detail as follows in conjunction with accompanying drawing:

[0026] see figure 1 , the abrasive slurry jet microporous nozzle inner runner processing equipment includes: an oil tank, a slurry tank and a high-pressure material tank, the inlet end of a high-pressure pipeline is connected to the oil tank and connected to an oil suction filter, a The other end of the oil pump and the two one-way valves are connected to the oil inlet of the high-pressure material tank; an oil return line is connected to the oil inlet of the high-pressure material tank, and connected to a stop valve and an oil return filter in sequence After that, the other end is connected to the oil tank; one end of a feed pipe is connected to the slurry tank, and connected to a slurry filter, a slurry pump and a stop valve in sequence, and the other end is connected to the feed port of the high-pressure material tank; One end of a feed pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com