A method for preparing carbon-silicon composite materials by biological method

A composite material and biological method technology, applied in the field of biological preparation of carbon-silicon composite materials, can solve the problems of chicken manure environmental pollution, carbon-silicon composite materials are prone to agglomeration, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

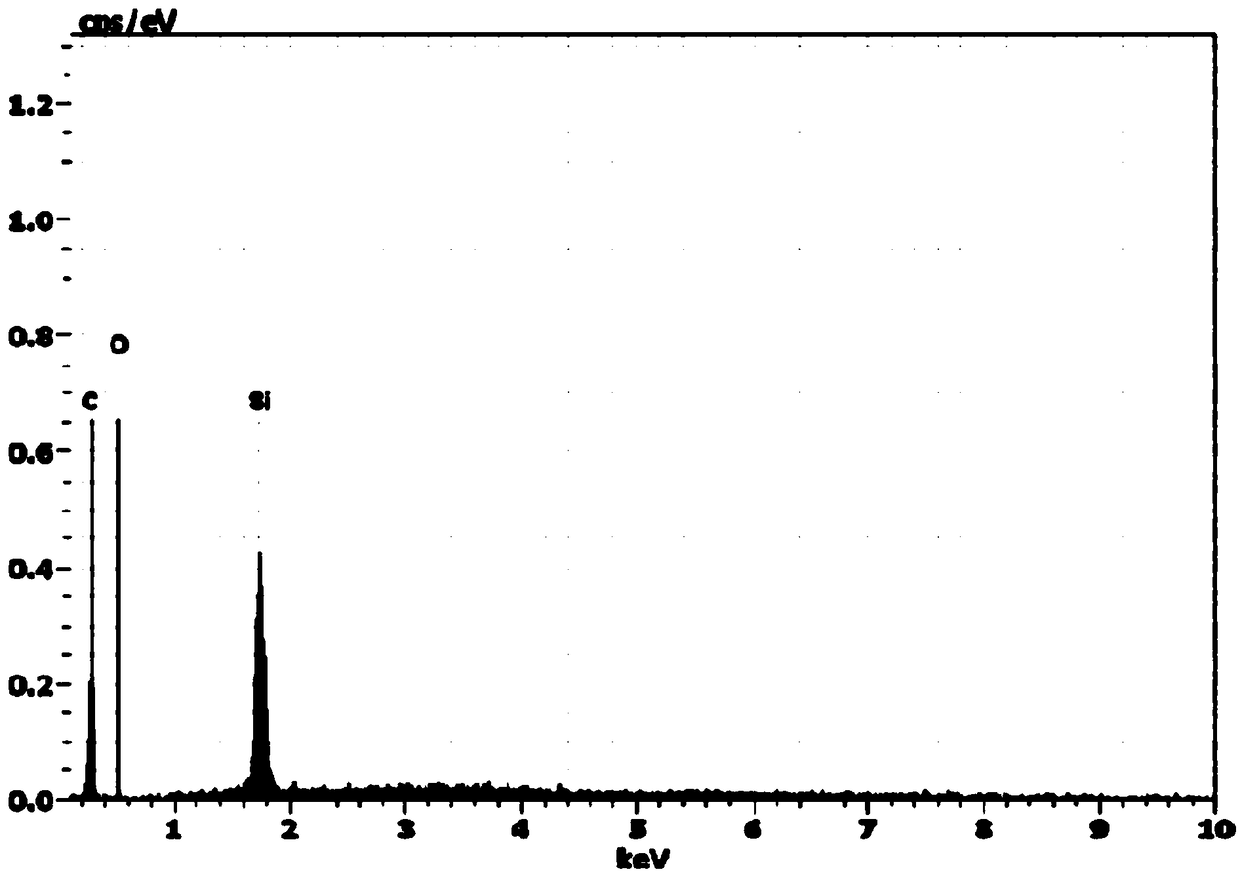

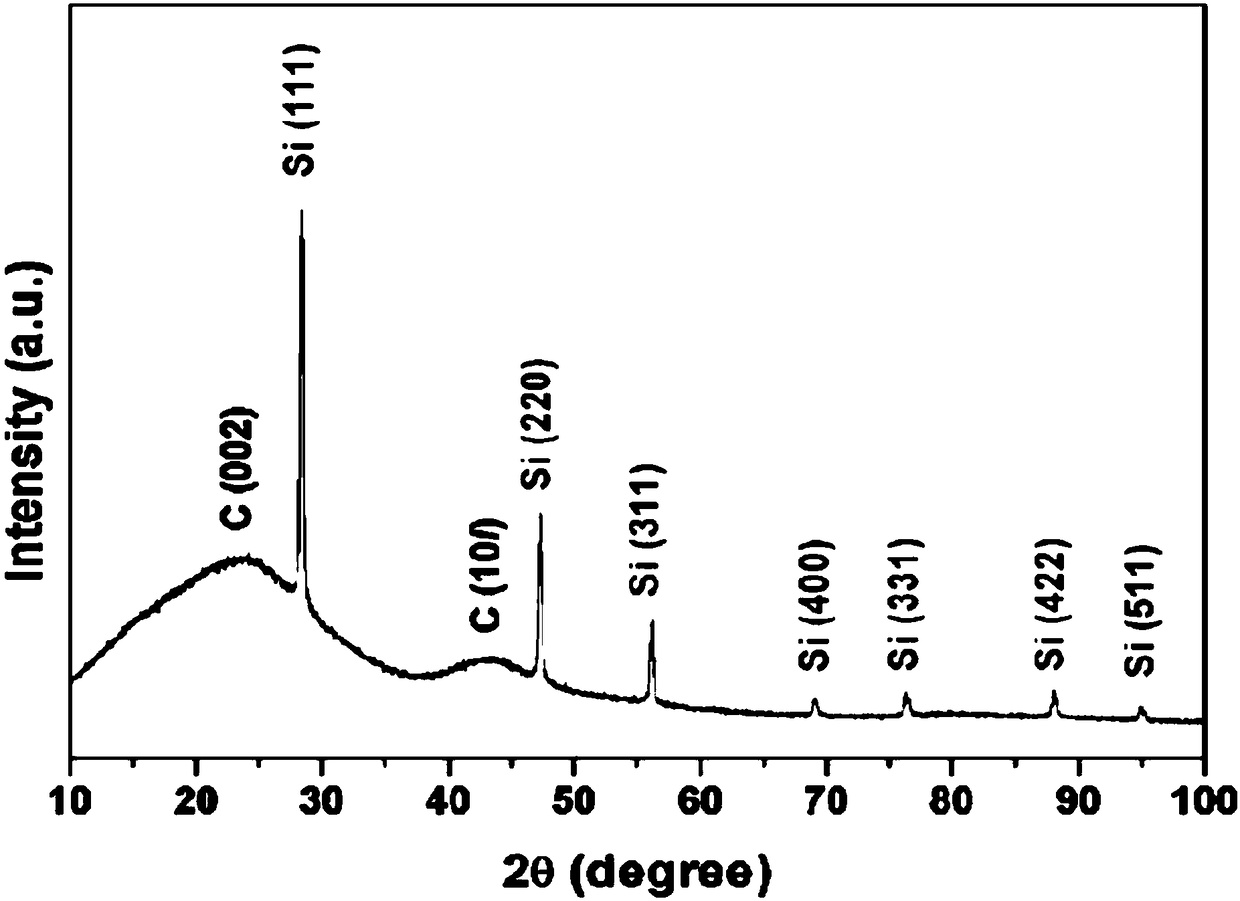

Embodiment 1

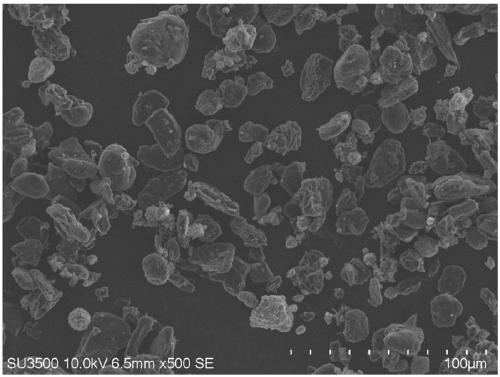

[0036]1. Weigh 100g of bean cake, soybean meal and corn flour respectively, place them in a muffle furnace, raise the temperature to 600°C at a heating rate of 5°C / min under a nitrogen atmosphere, and carry out high-temperature carbonization at a constant temperature for 4 hours, and then continue to Cool naturally to room temperature under a nitrogen atmosphere; take out the cooled residue, weigh it, and calculate the weight ratio before and after carbonization;

[0037] 2. Taking the preparation of 450mAh / g carbon-silicon composite material as an example, the carbon-silicon ratio in this material is calculated according to the formula Q=4200*x+372*(1-x), and the silicon-carbon ratio x is 0.0204;

[0038] 3. Mix soybeans, bean cakes, and bean curd powder in a weight ratio of 1:1:1 as raw materials for chicken feed. The raw materials for chicken feed and monocrystalline silicon are respectively pulverized into particles of 5-30 microns by a pulverizer, and then mixed according ...

Embodiment 2

[0046] 1. Weigh 100g of soybeans, bean cakes, and bean coriander powder respectively, place them in a muffle furnace, raise the temperature to 600°C at a heating rate of 5°C / min under a nitrogen atmosphere, and carry out high-temperature carbonization at a constant temperature for 4 hours, and then continue to Naturally cool to room temperature under the atmosphere; take out the cooled residue, weigh it, and calculate the weight ratio before and after carbonization;

[0047] 2. Taking the preparation of 450mAh / g carbon-silicon composite material as an example, the carbon-silicon ratio in this material is calculated according to the formula Q=1970*x+372*(1-x), and the silicon-carbon ratio x is 0.0488;

[0048] 3. Mix soybeans, bean cakes, and bean curd powder in a weight ratio of 1:1:1 as raw materials for chicken feed. The raw materials for chicken feed and silicon oxide-containing materials are respectively pulverized into particles of 5-30 microns by a pulverizer, and then ac...

Embodiment 3

[0056] 1. Weigh 100g of soy flour, corn flour and sorghum flour respectively, put them in a muffle furnace, raise the temperature to 600°C at a rate of 5°C / min under a nitrogen atmosphere, and carry out high-temperature carbonization at a constant temperature for 4 hours, and then continue Naturally cool to room temperature under a nitrogen atmosphere; take out the cooled residue, weigh it, and calculate the weight ratio before and after carbonization;

[0057] 2. Taking the preparation of 450mAh / g carbon-silicon composite material as an example, the silicon-carbon ratio in this material is calculated according to the formula Q=869*x+372*(1-x), and the silicon-carbon ratio x is 0.1569;

[0058] 3. Mix soybeans, bean cakes, and bean curd powder in a weight ratio of 1:1:1 as raw materials for chicken feed. The raw materials for chicken feed and materials containing silicon carbide are respectively pulverized into particles of 5-30 microns through a pulverizer, and then according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com