Multifunctional fast laser cutting device

A laser cutting and multi-functional technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of single device functionality and poor device practicability, and achieve the effect of improving practicability and functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solution of the invention described in the claims.

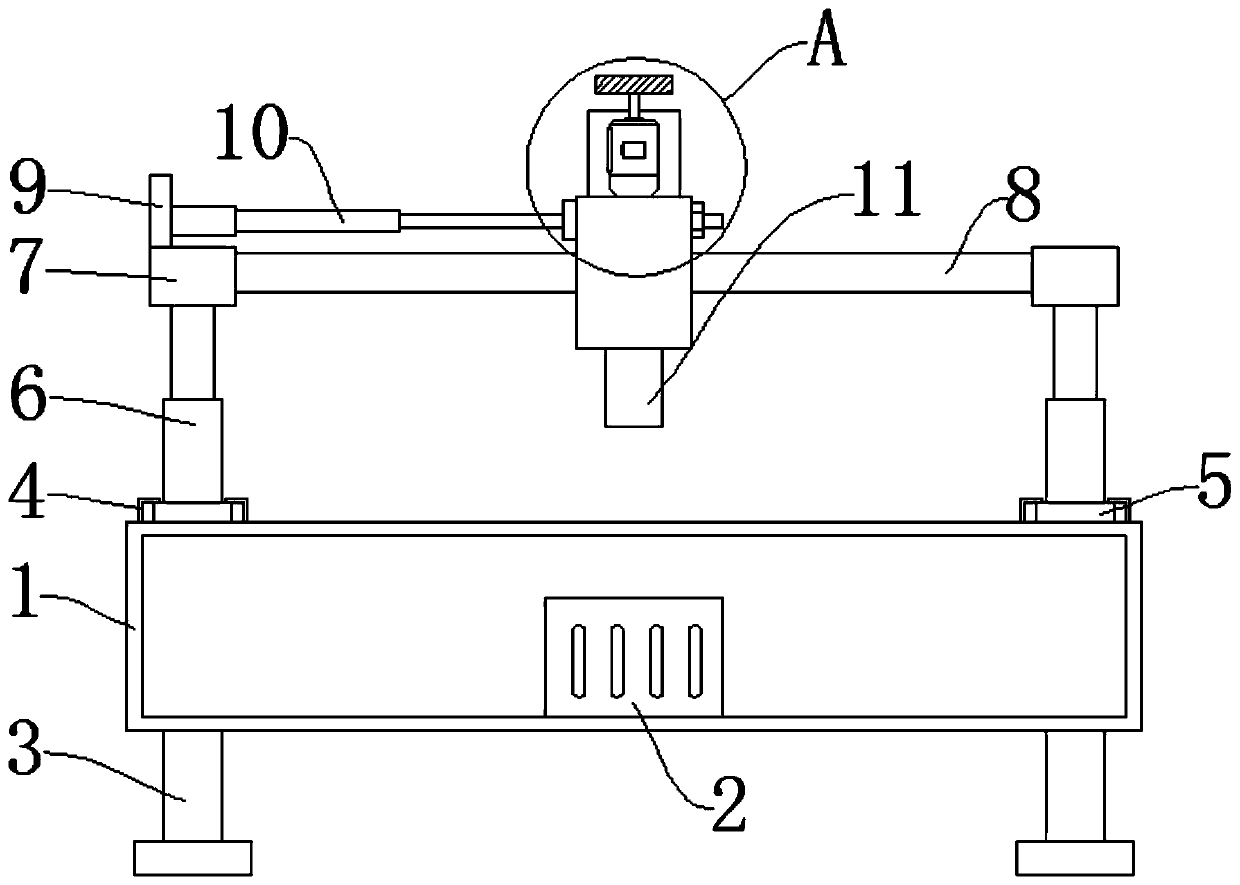

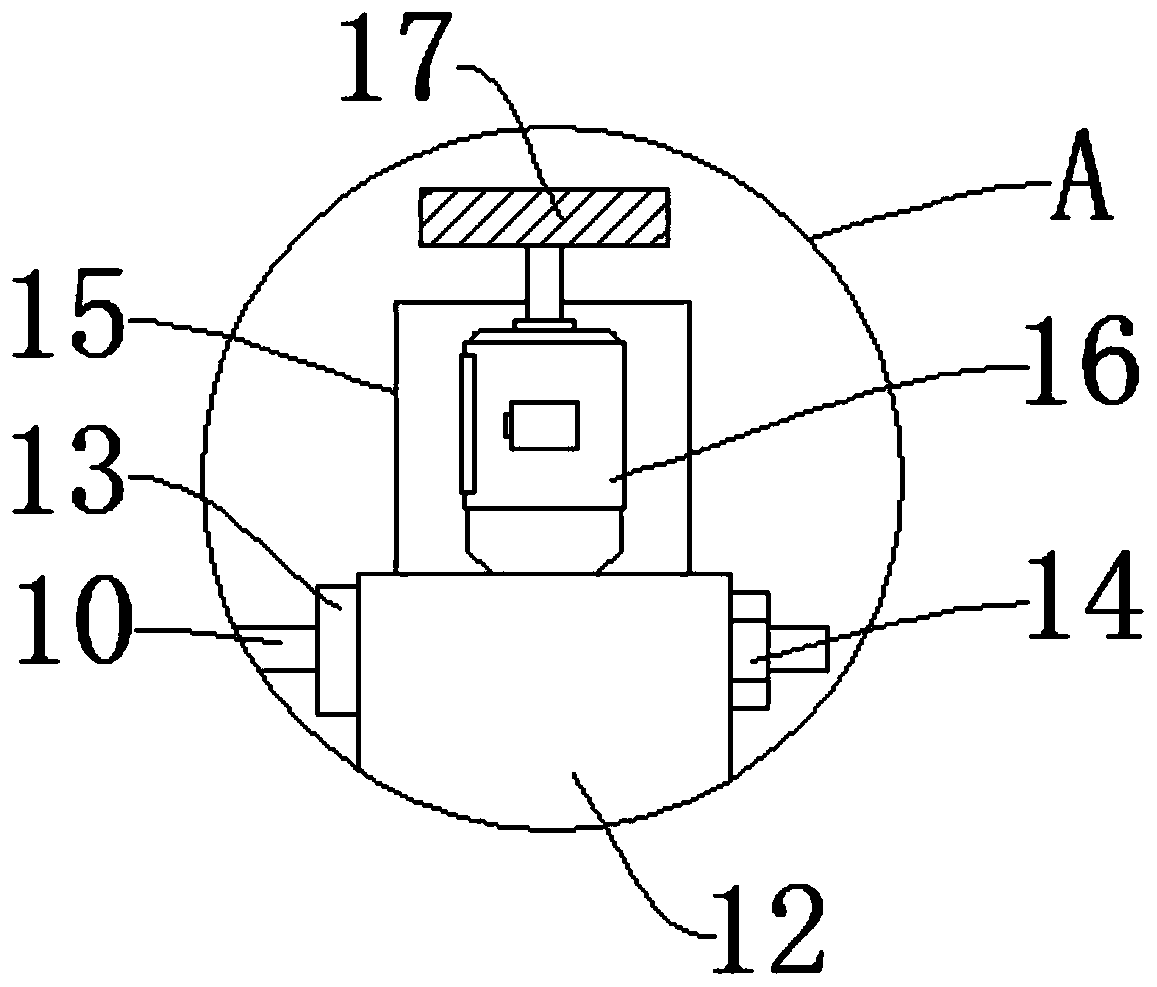

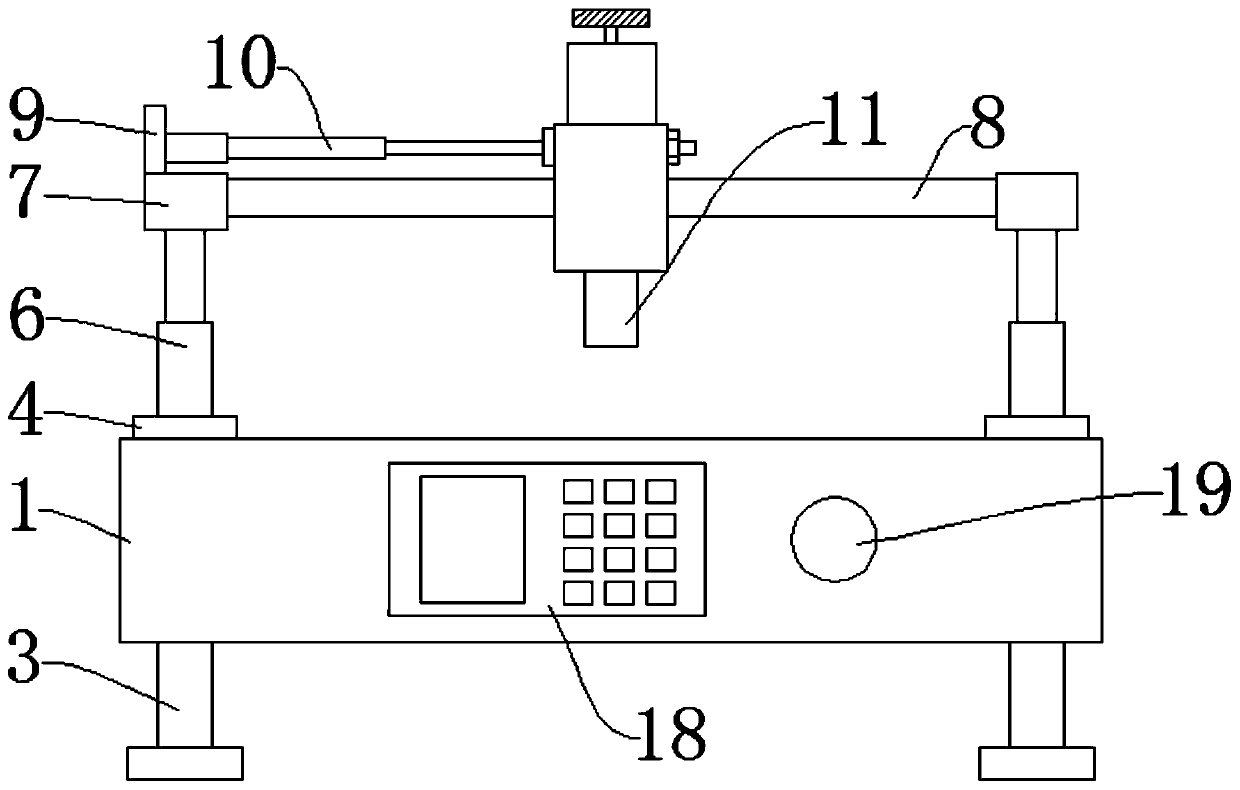

[0027] refer to Figure 1-Figure 5 , this specific embodiment provides a multifunctional fast laser cutting device, including a base 1, a controller 2, a control panel 18, and an emergency stop button 19. The inside of the base 1 is fixed with a controller 2 by screws, and the model of the controller 2 is FBS -60MCT / J, used to control the operation of the device. A control panel 18 is installed on the front of the base 1. The control panel 18 is used to set and display parameters. One side of the control panel 18 is provided with an emergency stop button 19. The emergency stop button 19 is used to To ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com