Glass fiber reinforced plastic pipeline intersecting line milling device based on industrial robot

A technology of industrial robots and milling devices, applied in the direction of machine tools, positioning devices, and metal processing machinery parts suitable for grinding workpiece edges, can solve the problems of harming the health of operators, harsh working environment at construction sites, and high labor intensity. Achieve moderate milling range and grinding range, avoid uncut and overcut collisions, facilitate position setting and attitude adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical solution, purpose and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

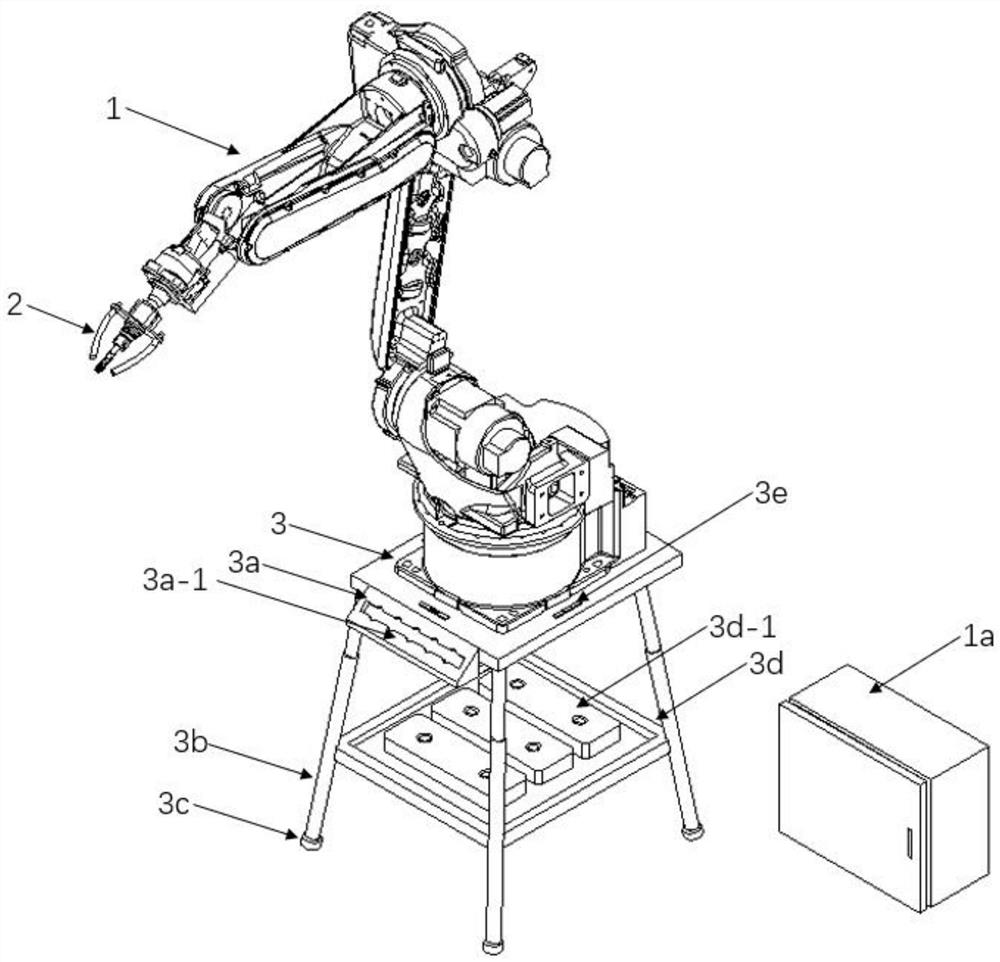

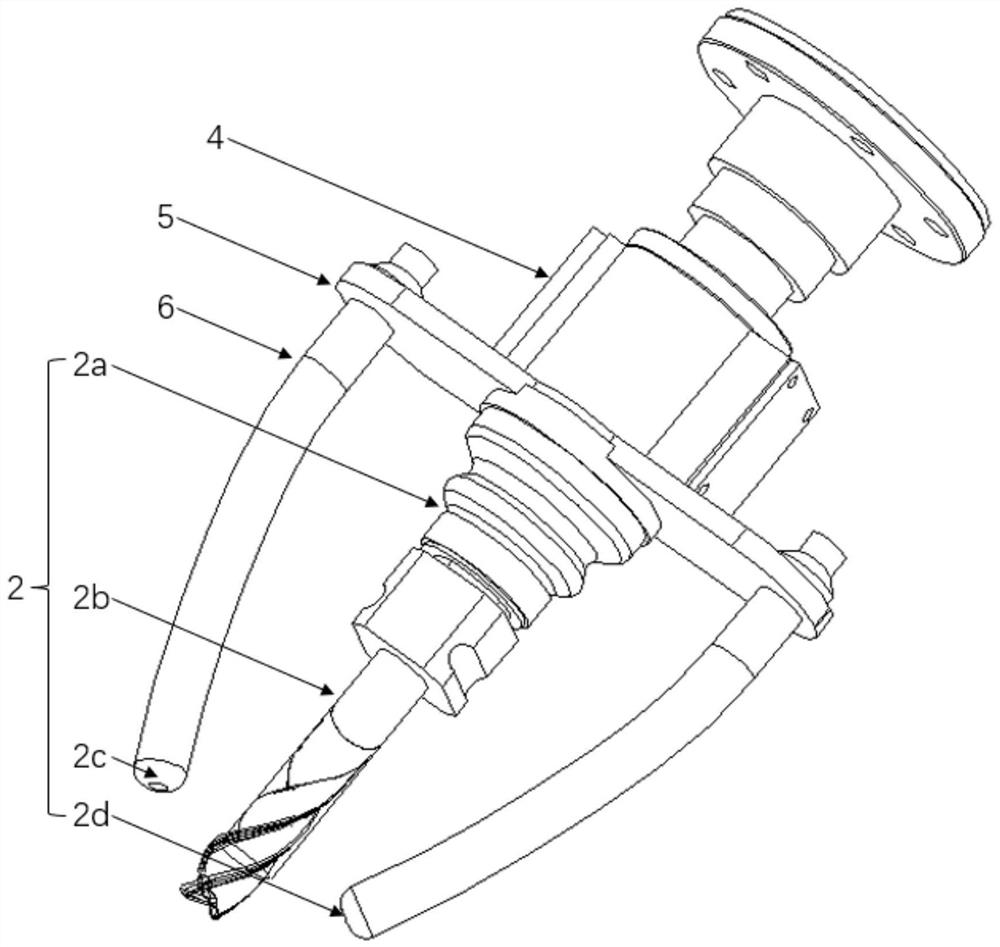

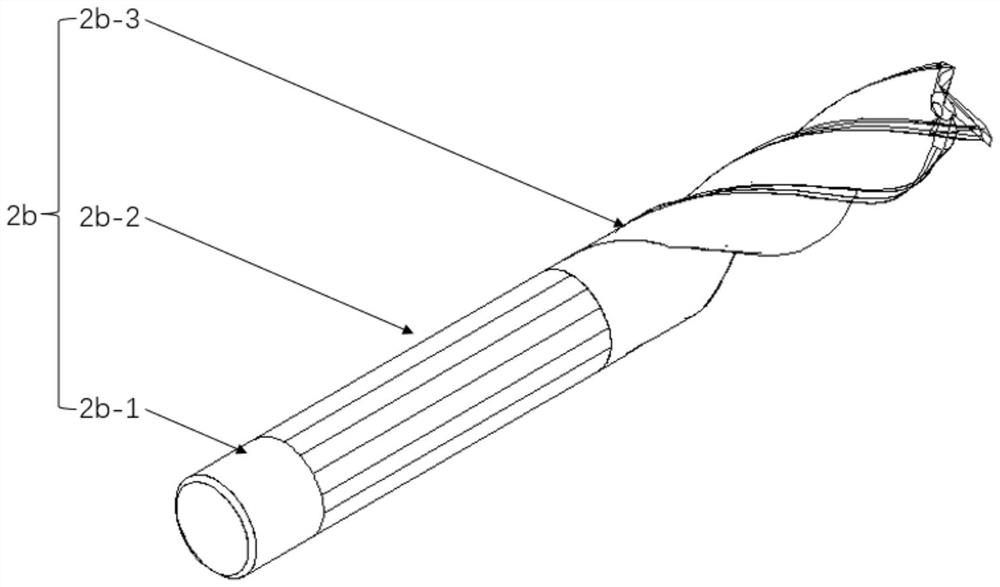

[0026] Such as Figure 1 ~ Figure 4 As shown, an industrial robot-based FRP pipe intersecting line milling device includes an industrial robot 1 and a milling head 2. The industrial robot 1 is controlled by the control cabinet 1a, and the control cabinet 1a precisely controls the movement of the robot, thereby milling the FRP pipe intersecting line The milling head 2 is arranged on the working end portion of the industrial robot 1, and the bottom of the industrial robot 1 is provided with a workbench 3, and the workbench 3 is used to support and fix the base of the industrial robot 1; the milling head 2 includes the electric spindle 2a, the electric spindle 2a The fixed end is connected to the end of the working joint of the industrial robot 1, and the rotating e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com