Grinding device and multifunctional flour milling machine

A technology of grinding device and grinding zone, applied in grain processing and other directions, can solve the problems of affecting the edible taste of products, influence of powder quality, long grinding time, etc., and achieve the effects of simple structure, good quality of finished products and high grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the orientation terms such as left, middle, right, up, and down in the examples of the present invention are only relative concepts or refer to the normal use state of the product, and should not be considered as restrictive .

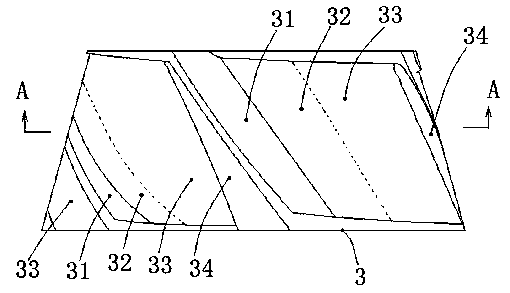

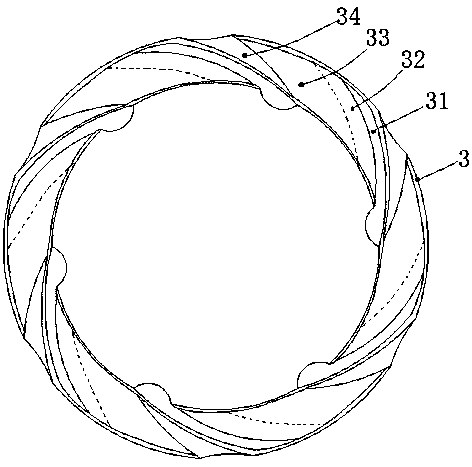

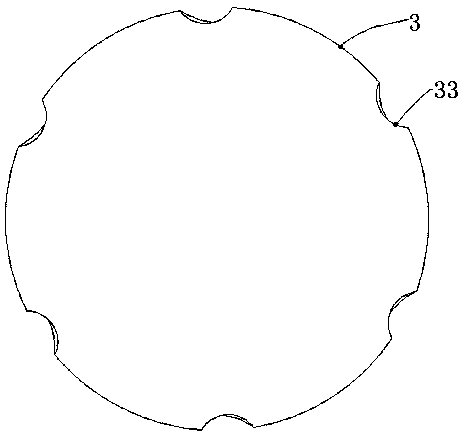

[0024] A grinding device such as Figure 7 As shown, it includes a cone-shaped inner roller 3, and an outer roller 4 is sleeved on the inner roller 3, combined with Figure 5 with Image 6 As shown, the inner wall of the outer roller 4 fits and rotates with the outer wall of the inner roller 3; Figure 1 to Figure 4 As shown, on the outer wall of the inner roller 3, there are several functional areas distributed along its circumference. In this embodiment, six functional areas are arranged continuously, and each of the functional areas includes the outer wall of the inner roller 3. The feeding zone 31, the buffer zon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com