Grinding accessory, swing power tool and application thereof

A technology for oscillating power tools and accessories, applied in grinding tools, grinding devices, grinding machine tools, etc., can solve the problems of workpieces that cannot grind concave curved surfaces, complex structures, etc., and achieve high fit, simple and compact structure, and tight fit. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

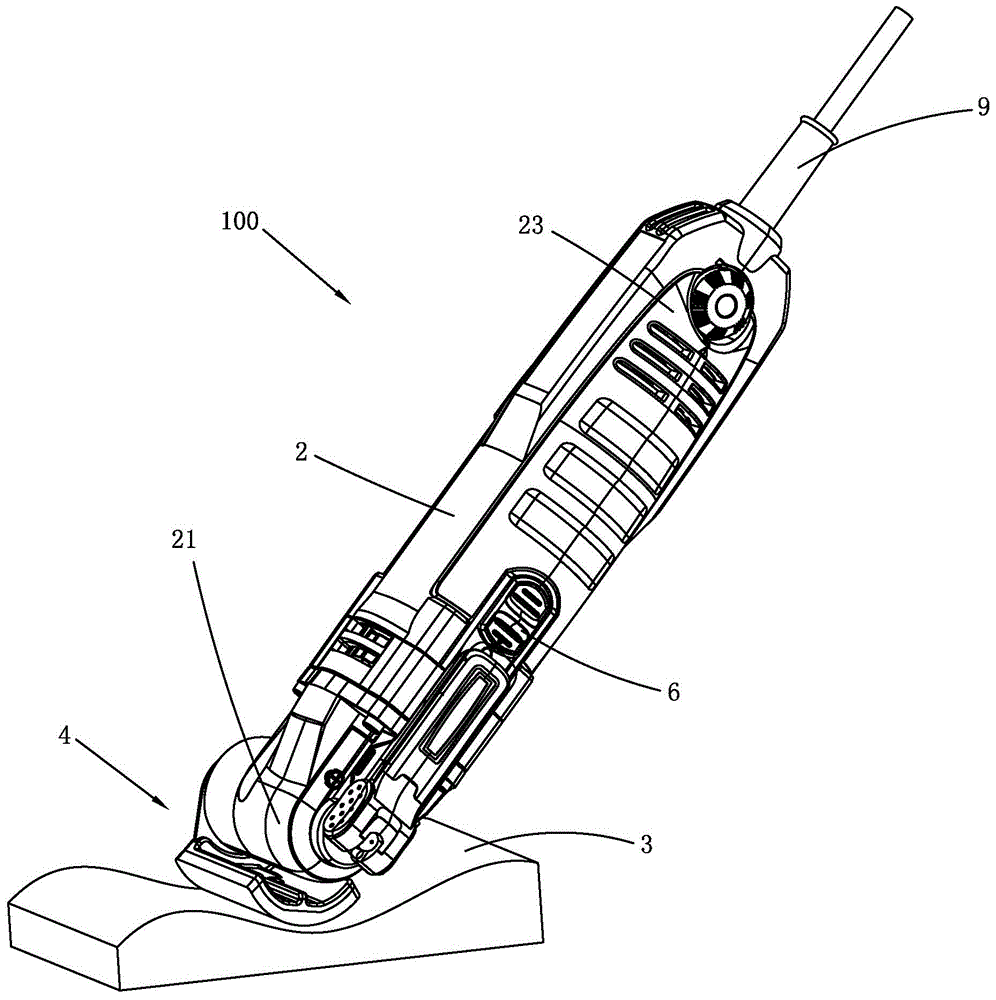

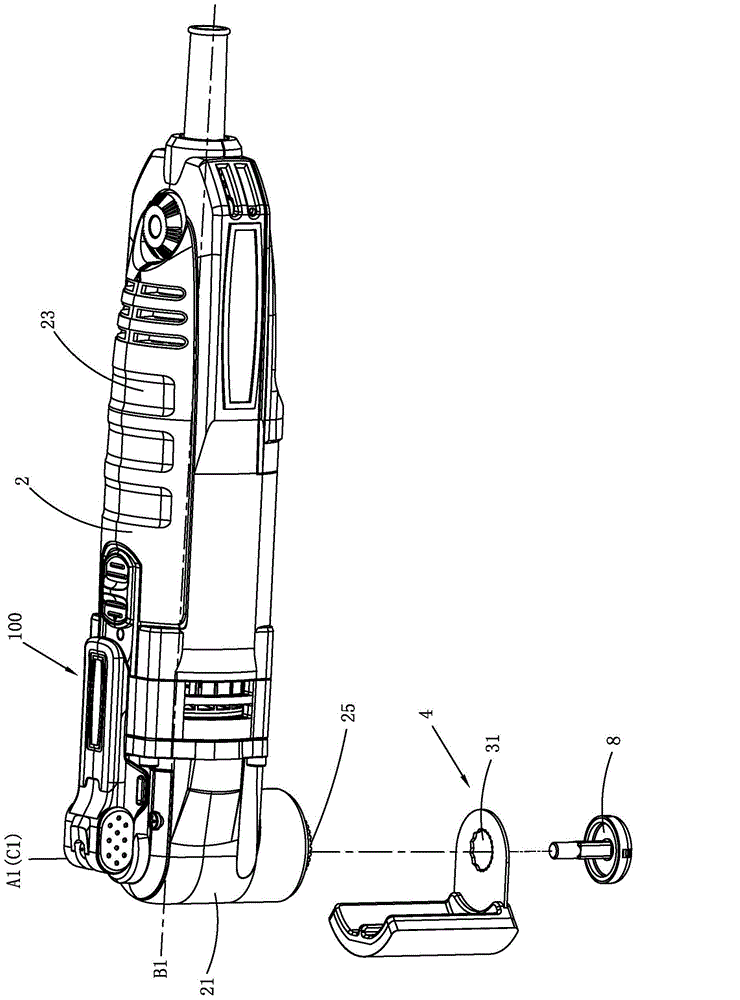

[0046] See figure 1 with figure 2 As shown, Embodiment 1 provides an oscillating power tool 100 equipped with a grinding accessory 4, which can be used for grinding workpieces 3 with curved surfaces, especially for grinding workpieces with concave surfaces.

[0047] The oscillating power tool 100 includes: a housing 2 , a motor (not shown), a transmission mechanism (not shown), and a grinding attachment 4 . Wherein, the casing 2 extends along the longitudinal direction, has a longitudinal axis B1, defines figure 1 In the oscillating power tool 100 shown in , the side close to the grinding attachment 4 in the direction of the longitudinal axis B1 is referred to as "front", and the side away from the grinding attachment 4 is referred to as "rear".

[0048] The housing 2 includes a head shell 21 located at the front of the oscillating power tool 100 and a tail shell 23 disposed at the rear of the head shell 21 . The motor is arranged inside the tail case 23, and the transmiss...

Embodiment approach 2

[0067] Embodiment 2 of the present invention discloses an oscillating power tool 200 equipped with a grinding accessory 40 .

[0068] see Figure 5 As shown, the oscillating power tool 200 is basically the same as the oscillating power tool 200 in the first embodiment, the difference is the grinding part 42 of the grinding attachment 40 .

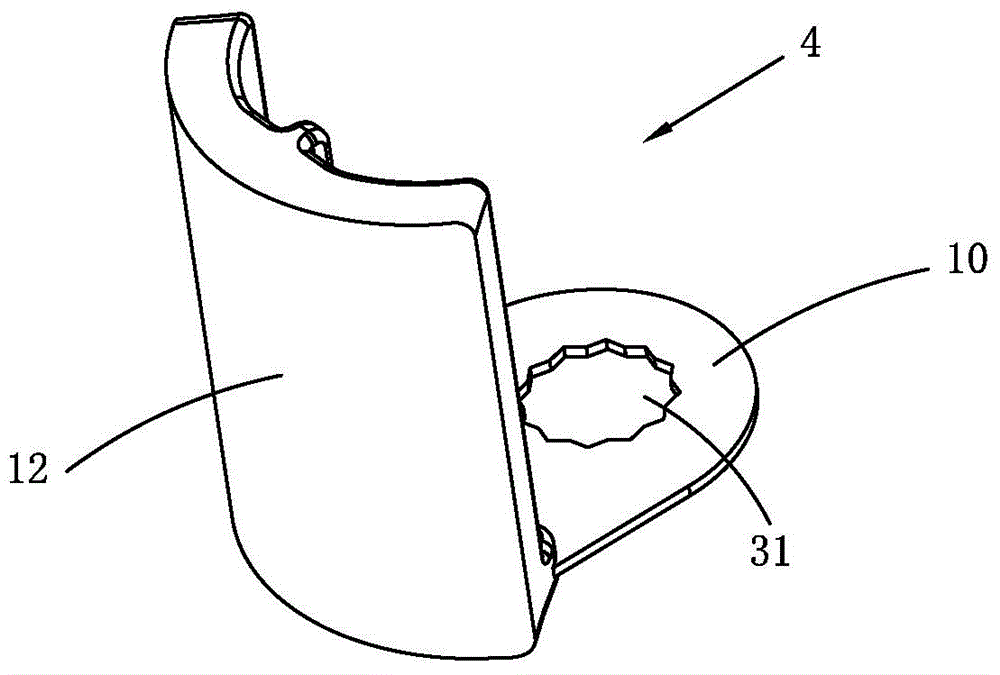

[0069] The grinding attachment 40 is connected to the output shaft of the oscillating power tool 200 through a locking member 46 . The grinding part 42 has a mounting surface 44 for mounting grinding parts. The mounting surface 44 is a curved surface with a generatrix 45 inside the curved surface. The mounting surface 44 can be regarded as being formed by extending the generatrix 45 along a curve 47, and the curve 47 is the movement of the generatrix 45. track line. Preferably, the busbar 45 is a straight line, and the busbar 45 is parallel to the axis A1 of the output shaft. The transmission part 41 is disposed at one end of the grindin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com