a sealing valve

A technology for sealing valves and sealing surfaces, which is applied in the direction of lifting valves, valve devices, valve details, etc., and can solve problems such as unsatisfactory sealing, coking of ball valves, secondary cracking, and coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

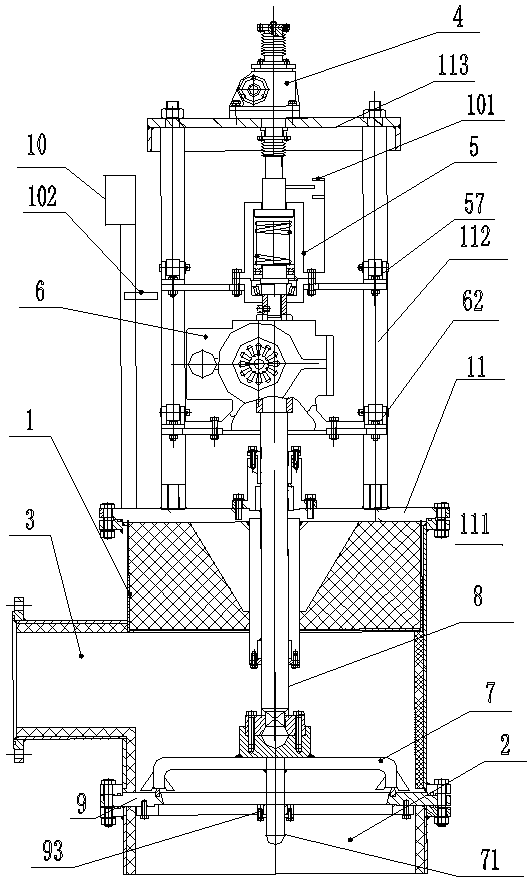

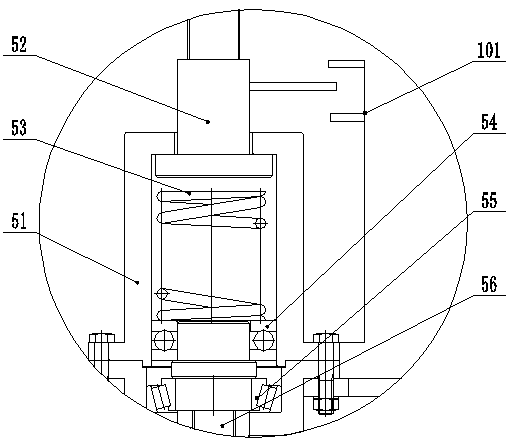

[0033] Embodiment one: as figure 1 , image 3 , Figure 4As shown, a sealing valve includes a valve body 1, an air inlet 2, an air outlet 3, a valve core opening and closing mechanism 4, a load control mechanism 5, a valve core rotating mechanism 6, a valve core 7, and a valve stem 8. The valve body 1 is provided with an air inlet 2 and an air outlet 3, the air inlet 2 is provided with a valve seat 9, the valve seat 9 is connected with the valve core 7, and the valve core 7 is connected with the valve stem 8 , the valve stem 8 passes through the valve body 1 and is connected to the valve core rotating mechanism 6, and the valve core rotating mechanism 6 is connected to the valve core opening and closing mechanism 4 through the load control mechanism 5, and the valve The rotary motion of the core rotating mechanism 6 and the linear motion of the valve core opening and closing mechanism 4 become relatively independent motions through the load control mechanism 5 .

[0034] Th...

Embodiment 2

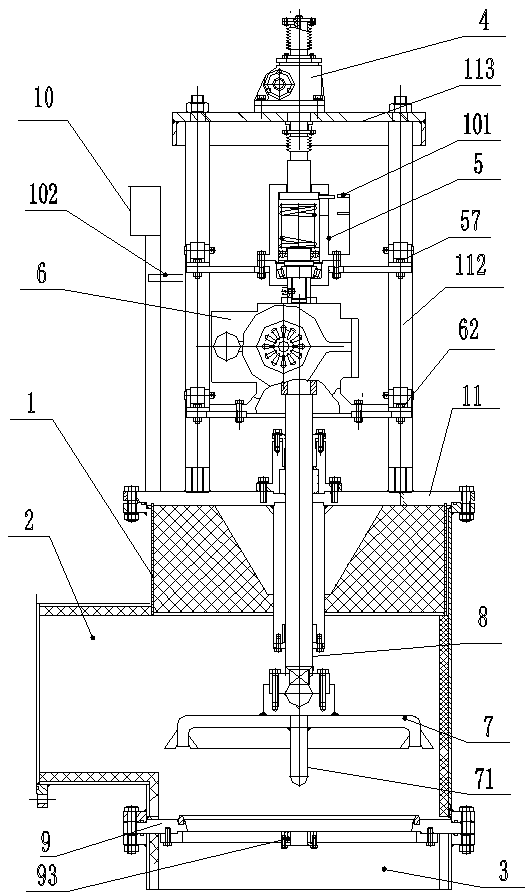

[0047] Embodiment two: if figure 2 , image 3 , Figure 4 As shown, a sealing valve includes a valve body 1, an air inlet 2, an air outlet 3, a valve core opening and closing mechanism 4, a load control mechanism 5, a valve core rotating mechanism 6, a valve core 7, and a valve stem 8. The valve body 1 is provided with an air inlet 2 and an air outlet 3, and the air outlet 3 is provided with a valve seat 9, the valve seat 9 is connected with the valve core 7, and the valve core 7 is connected with the valve stem 8, The valve stem 8 passes through the valve body 1 and is connected to the valve core rotating mechanism 6, the valve core rotating mechanism 6 is connected to the valve core opening and closing mechanism 4 through the load control mechanism 5, and the valve core The rotary motion of the rotating mechanism 6 and the linear motion of the valve core opening and closing mechanism 4 become relatively independent motions through the load control mechanism 5 .

[0048] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com