Stirring shaft with stirring and grinding functions

A stirring shaft and functional technology, which is applied in the field of stirring shafts with stirring and grinding functions, can solve the problems of consuming manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

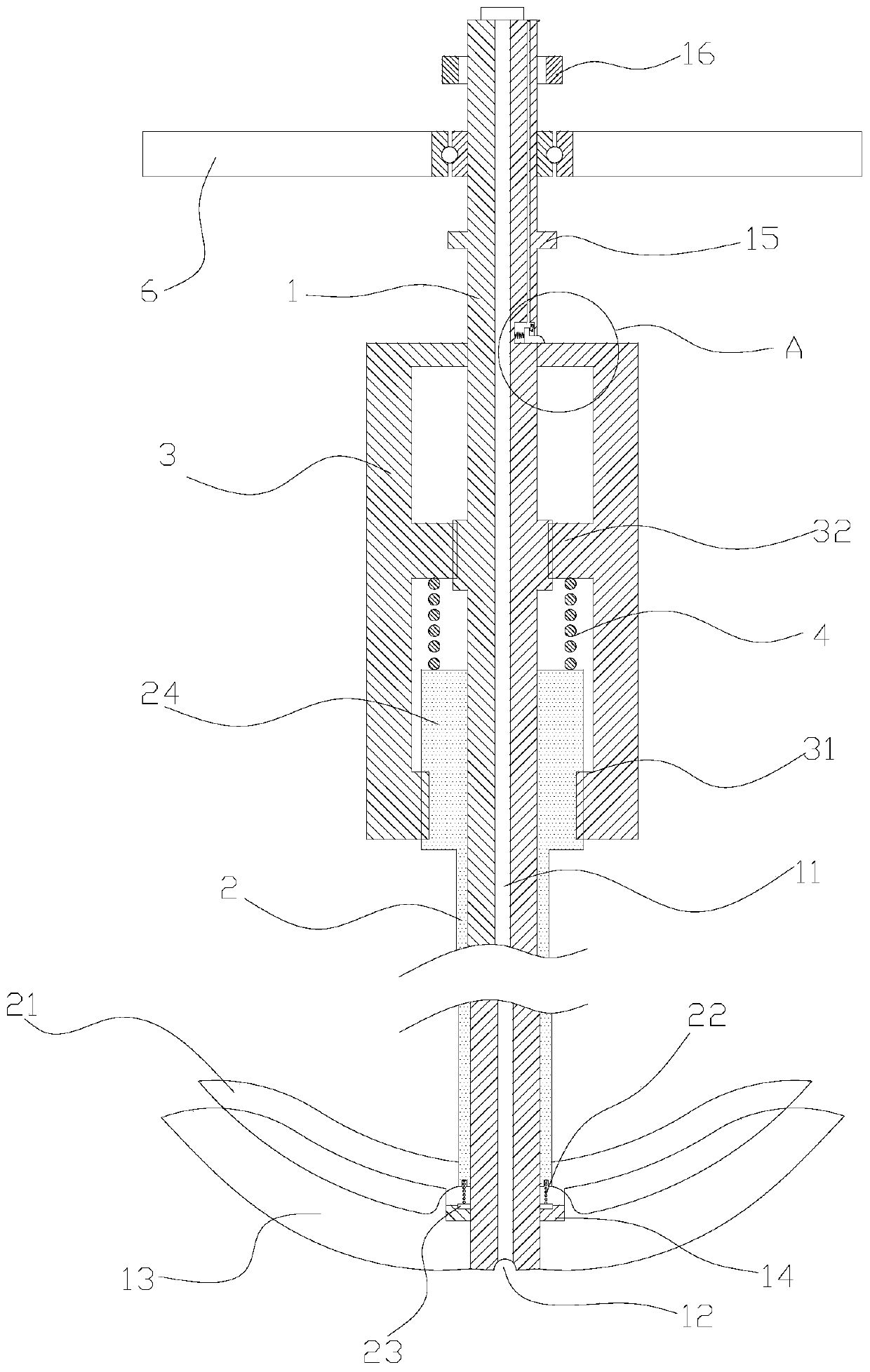

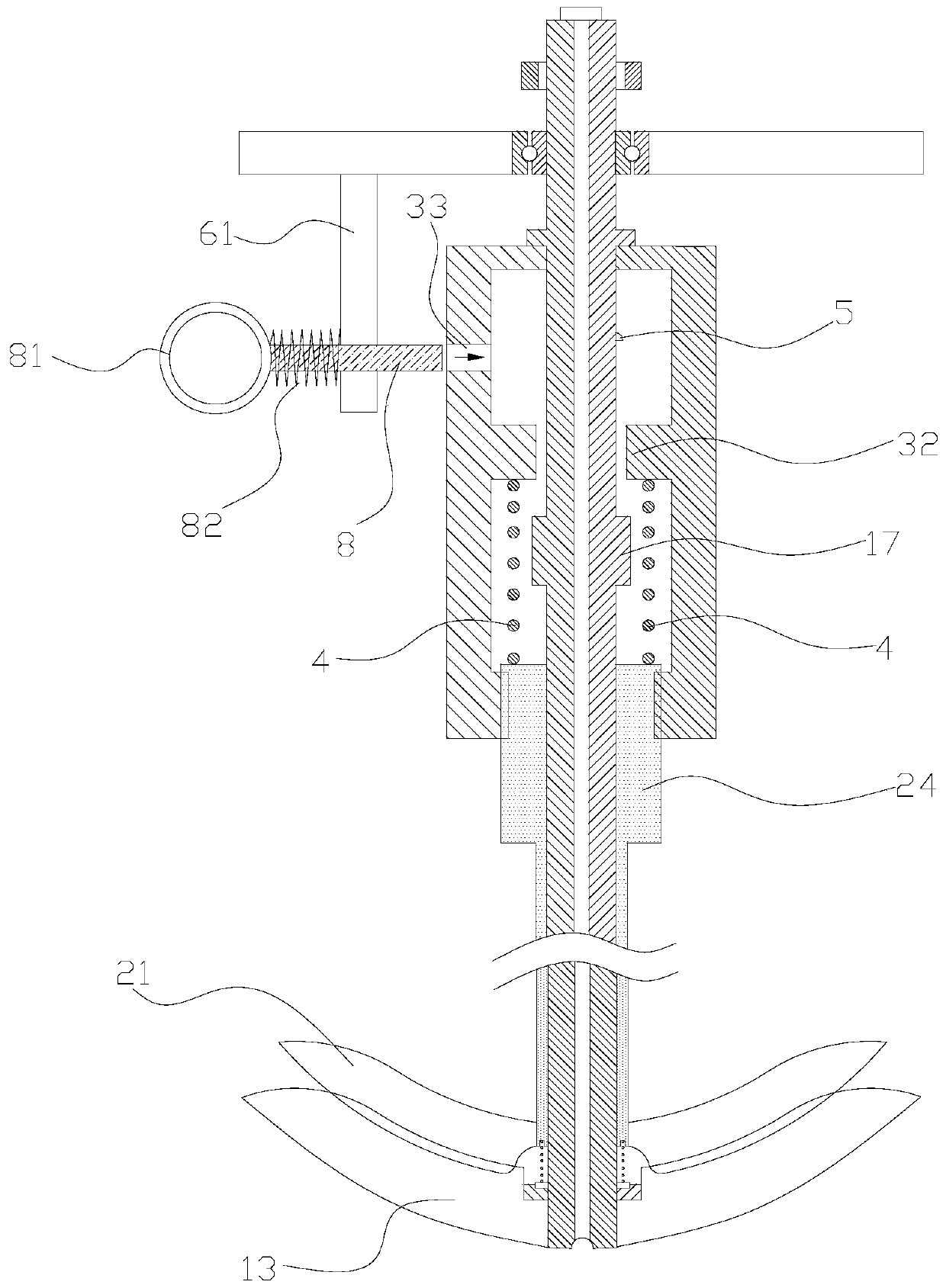

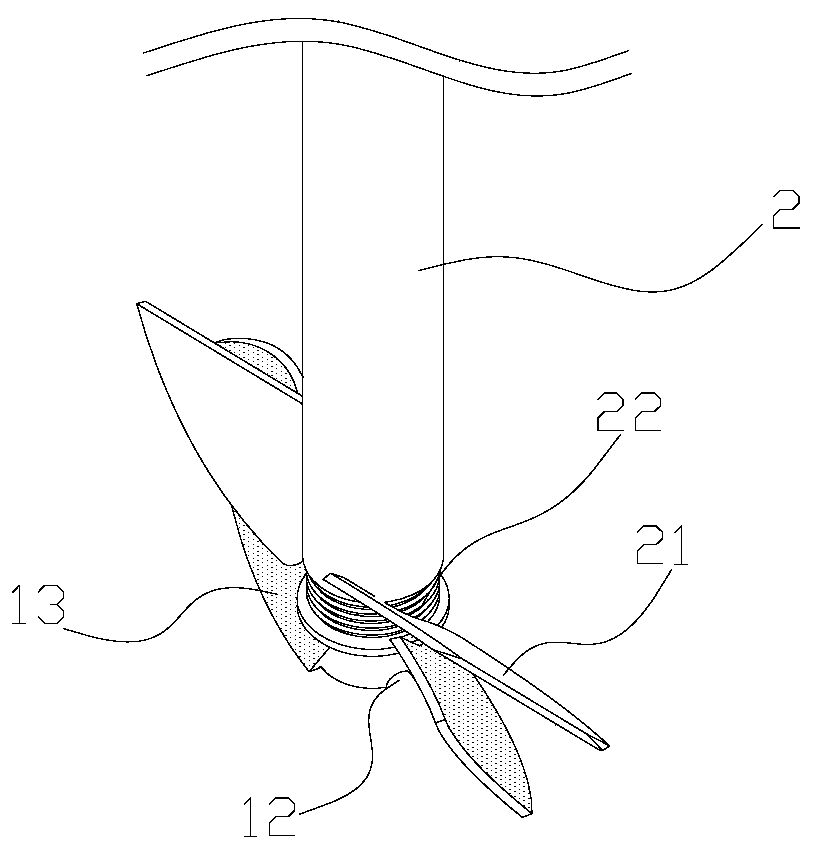

[0029] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

[0030] as attached figure 1 to attach Figure 11 As shown, the stirring shaft with stirring and grinding functions mainly includes an inner shaft 1 , an outer shaft 2 and a sleeve 3 . The outer shaft 2 is rotatable and can slide up and down on the outer side of the inner shaft 1. Specifically, the outer shaft 2 with a smooth inner surface can be directly placed on the inner shaft 1 with a smooth outer surface, or a hydraulic cylinder can also be used. Or the cylinder block and the piston rod sleeve structure of the cylinder. The sleeve 3 is sleeved on the outside of the outer shaft 2 .

[0031] A discharge channel 11 is provided in the middle of the inner shaft 1 and one or more feed ports 12 are provided on the side of the lower end of the inner shaft 1 , and liquid or powder materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com