Industrial abrasive band based on chopped linen fibers

A chopped fiber, industrial technology, applied in the field of industrial abrasive belts, can solve problems such as poor mechanical properties, difficult elastic modulus, and abrasive belt base materials that do not have grinding functions, and achieve low cost and improved tear resistance Performance, the effect of various performance improvements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the drawings and embodiments:

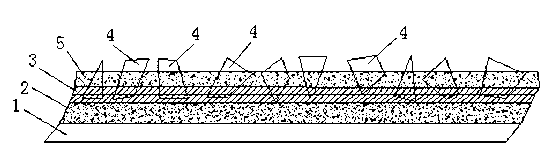

[0018] Such as figure 1 As shown, this embodiment takes sisal cloth as an example to illustrate the manufacturing process of the present invention as follows: the industrial abrasive belt substrate is first dipped or dipped with glue, which can be scratched or dipped one or more times, and the other side of the substrate The back squeegee glue forms the back squeegee layer, and then coats the primer. After the primer is applied, the sand is planted and the abrasive is implanted, and then the rubber is applied. After curing, the industrial abrasive belt can be obtained. The present invention is coating the primer, or In the process of dipping with glue, or back scraping, or re-gluing, sisal chopped fibers can be added in any one or more processes to make the force gap between the warp and weft of the substrate smaller. Increase the amount of bonding points, enhance it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com