Novel inductor iron core

An inductor and iron core technology, applied in the field of new inductor iron cores, can solve the problems of heavy weight, low high frequency loss, high noise, etc., and achieve the effect of small size and weight, reducing additional loss and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

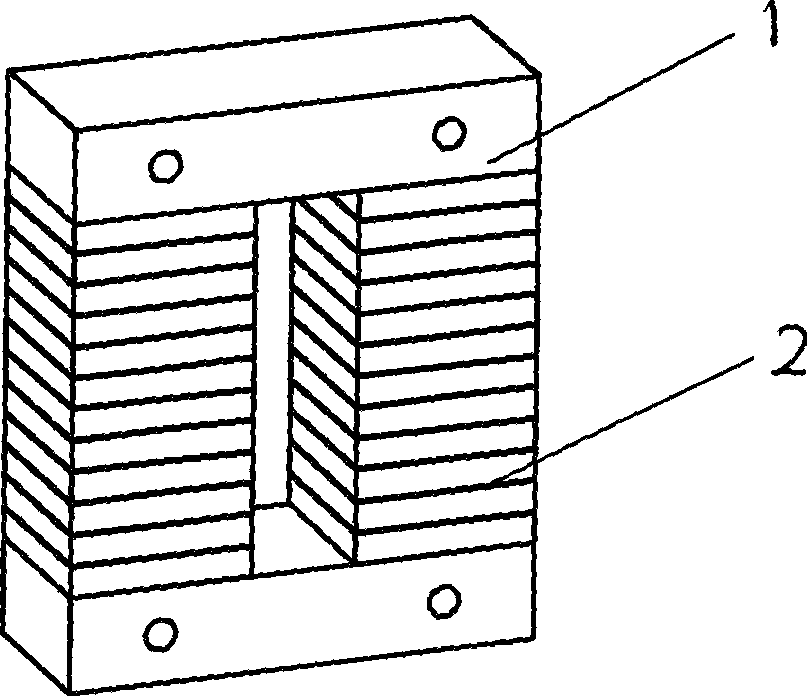

[0023] Example 1 Silicon steel sheet and ferrite composite core inverter output filter inductor

[0024] Filter inductor technical parameters:

[0025] Current: 106A, inductance: 0.9mH, current harmonics of 5.6kHz and other frequencies are about 25A.

[0026] In the prior art, the CD-shaped iron core made of 0.23mm cold-rolled grain-oriented silicon steel sheet has a loss of about 520W and a high temperature rise, which cannot meet the design requirements.

[0027] In the inductor core of the present invention, the iron yoke is made of non-oriented silicon steel sheet, and the core column is made of stacked rectangular ferrite magnetic sheets, such as Figure 1 shown. The loss is reduced to about 245W, the loss is reduced by 53%, and the temperature rise is significantly reduced, which meets the design requirements.

Embodiment 2

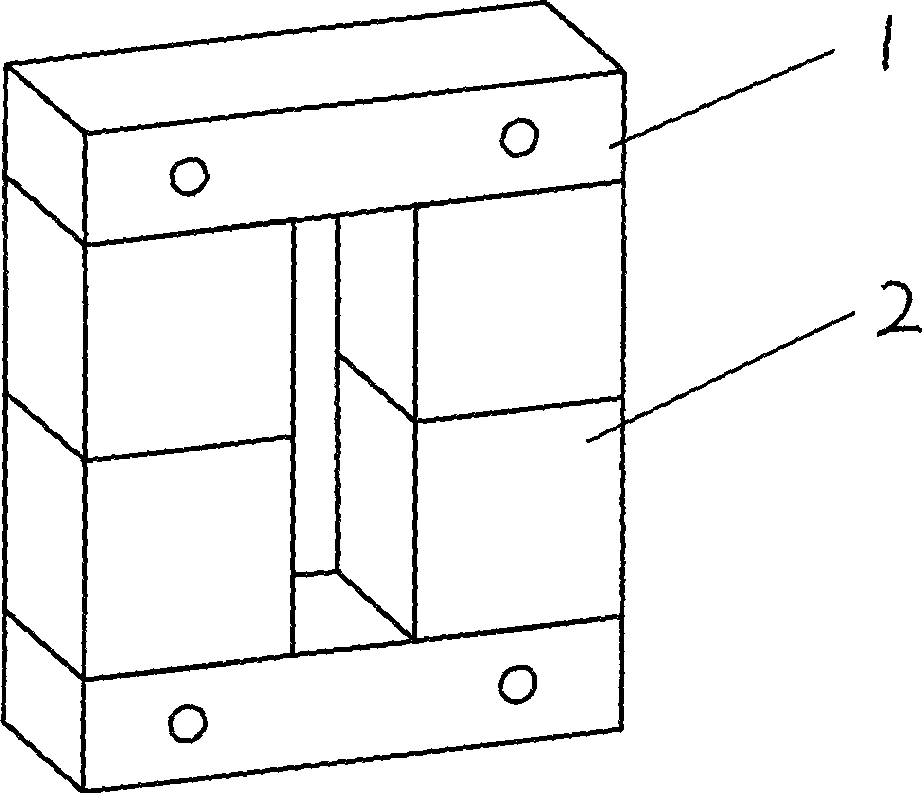

[0028] Example 2 Freewheeling Inductor of PWM Rectifier with Composite Iron Core of Silicon Steel Sheet and Iron Powder Core

[0029] PWM rectifier freewheeling inductance:

[0030] Current: 60A, inductance: 1.1mH, and current harmonics of 9.8kHz and other frequencies are about 12.5A.

[0031] In the prior art, the laminated iron core made of 0.18mm cold-rolled grain-oriented silicon steel sheet has a loss of about 280W and a high temperature rise, which cannot meet the design requirements.

[0032] Inductance iron core of the present invention, its iron yoke is 0.23mm cold-rolled grain-oriented silicon steel sheet, and iron core post uses rectangular iron powder core, as Figure II shown. The loss is reduced to about 165W, the loss is reduced by 41%, and the temperature rise is significantly reduced, which meets the design requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com