Special-winding energy-saving three-phase asynchronous motor

A three-phase asynchronous, special winding technology, which is applied in the field of electric motors, can solve the problems of inconspicuous energy saving, fluctuations in the rate of increase, and increased production costs, and achieve good starting performance, elimination of magnetic potential, and improved use efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

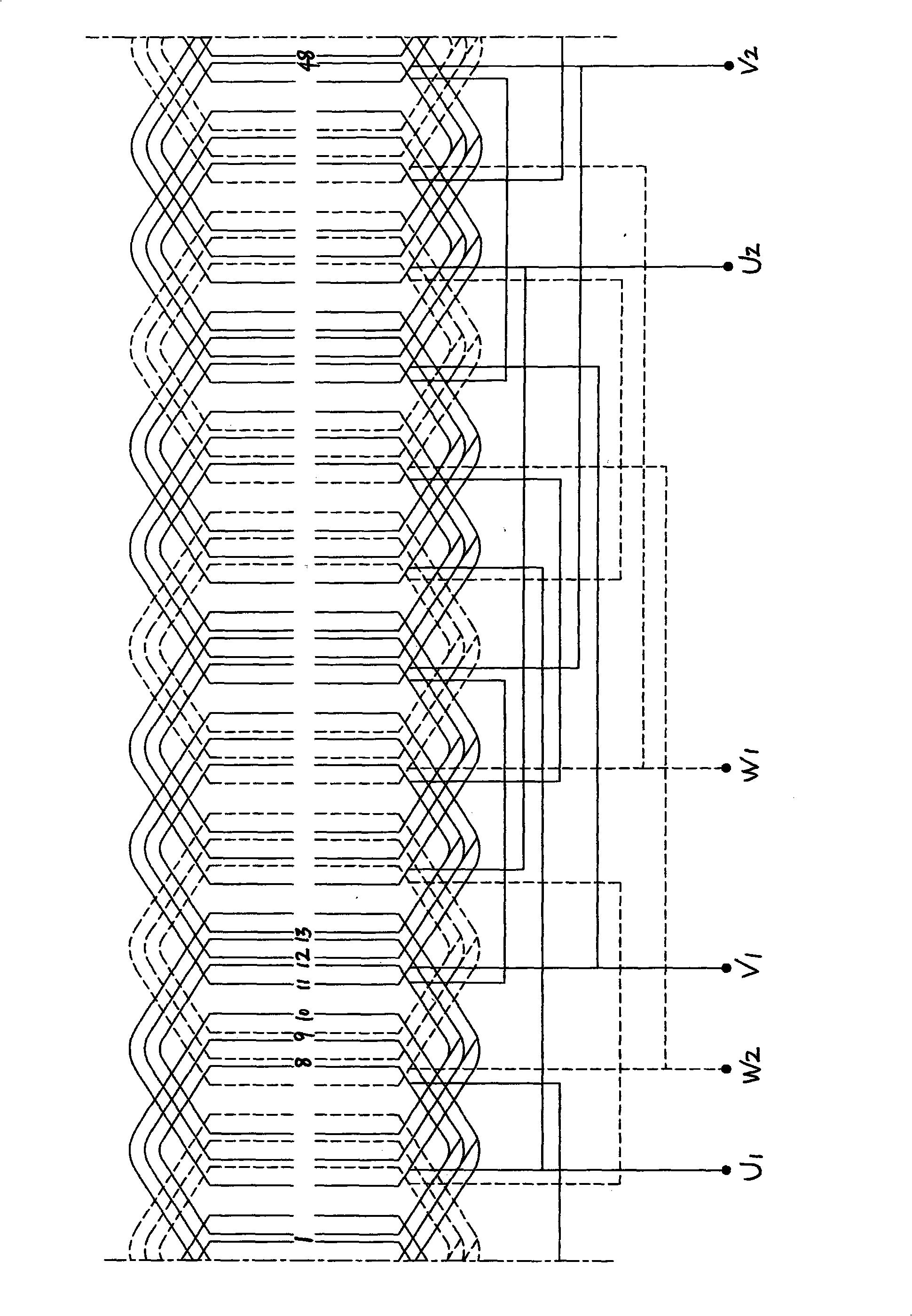

[0009] Taking the Y2-180M-4-pole-18.5KW motor as an example, the number of stator slots is 48, the number of magnetic poles is 4, the number of coils per slot is 36 turns, and the number of slots per pole and phase is 48 / (4×3) = 4. It can be seen from the attached drawings that V1, U1, and W1 in the figure are the incoming wire terminals, V2, U2, and W2 are the outgoing wire ends, the leftmost end is the first slot, and the rightmost end is the 48th slot. Equal-turn winding, the whole pitch is a single-layer winding, and the short pitch is a double-layer winding. The turns of the upper and lower coils of the double-layer winding are unequal turns. The 11th slot in the figure is a single-layer 36 turns, and the 12th slot is a double-layer. The lower layer is 0.55×36=20 circles, the 13th slot is the double-layer lower layer 0.45×36=16 circles; the 10th slot is the single-layer 36 circles, the 9th slot is the double-layer lower layer 0.55×36=20 circles, the 8th slot Be the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com