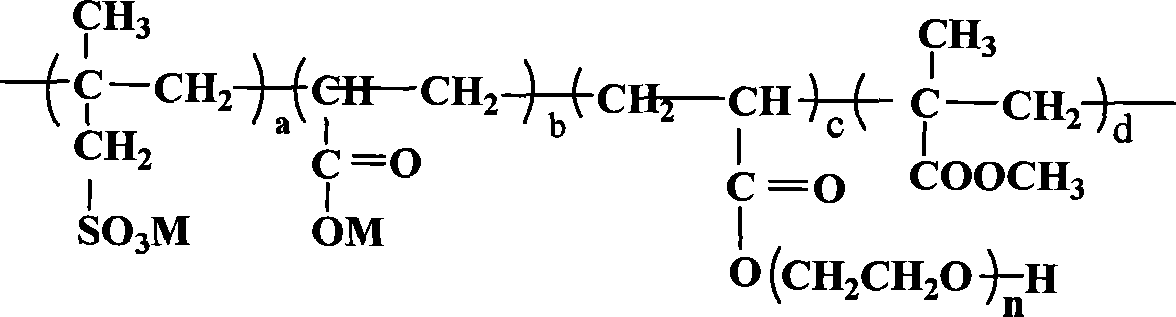

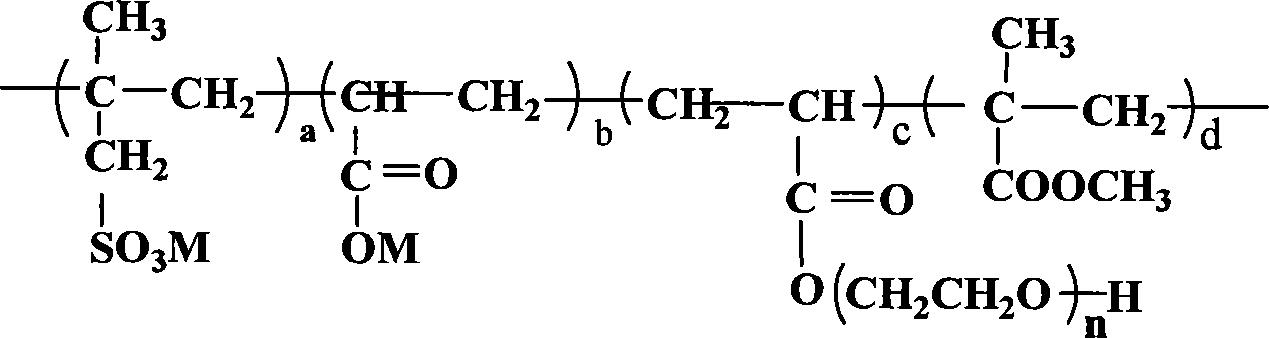

Polycarboxylic acids series water reducer and method for making same

A polycarboxylic acid-based, water-reducing agent technology, applied in the field of building materials, can solve the problems of poor control of cement plasticizing effect and low water-reducing rate, and achieves overcoming poor control of plasticizing effect, stable performance, and excellent plasticity. effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment is a polycarboxylate water reducer prepared by the following method:

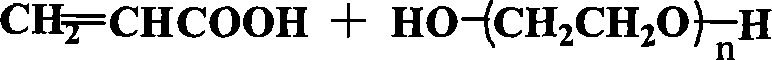

[0037] The first step, esterification reaction: take PEG 1 (Molecular weight 800) 32g (0.04mol), PEG 2 (Molecular weight 600) 24g (0.04mol), PEG 3 (Molecular weight 400) 8g (0.02mol), put into the 250mL four-necked bottle that breakpoint thermometer, condenser tube, agitator, separatory funnel are housed, add 15g 3A type molecular sieves (spherical shape, diameter 3~5mm) simultaneously; Add 6.92mL (0.1mol) of acrylic acid in a continuous dropwise manner, and the dropwise addition is completed within 1.5 hours; at the same time, add 0.71g of catalyst p-aminobenzenesulfonic acid and 0.008g of polymerization inhibitor hydroquinone, and carry out esterification reaction at 95°C , After 5h, polyoxyethylene allyl ester (PA) was obtained.

[0038] The second step, polymerization reaction: add 9.54g (0.06mol) MAS and appropriate amount of distilled water in the 1000mL four-necked flask tha...

Embodiment 2

[0041] This embodiment is a polycarboxylate water reducer prepared by the following method:

[0042] The first step, esterification reaction: take PEG 1 (Molecular weight 800) 32g (0.04mol), PEG 2 (Molecular weight 600) 24g (0.04mol), PEG 3 (Molecular weight 400) 8g (0.02mol), put into the 250mL four-necked bottle that breakpoint thermometer, condenser tube, agitator, separatory funnel are housed, add 15g 3A type molecular sieves (spherical shape, diameter 3~5mm) simultaneously; Add 9mL (0.13mol) of acrylic acid in a continuous dropwise manner, and the dropwise addition is completed within 1.5 hours; at the same time, add 0.71g of catalyst p-toluenesulfonic acid and 0.01g of polymerization inhibitor hydroquinone, and carry out esterification reaction at 90°C , After 5h, polyoxyethylene allyl ester (PA) was obtained.

[0043] The second step, polymerization reaction: add 31.8g (0.2mol) MAS and appropriate amount of distilled water to be mixed with 20% solution in the 1000mL ...

Embodiment 3

[0046] This embodiment is a polycarboxylate water reducer prepared by the following method:

[0047] The first step, esterification reaction: take PEG 1 (Molecular weight 1500) 60g (0.04mol), PEG 2 (molecular weight 1000) 40g (0.04mol), PEG 3 (Molecular weight 600) 12g (0.02mol), put into the 250mL four-necked bottle that breakpoint thermometer, condenser, stirrer, separatory funnel are housed, add 15g 3A molecular sieves (spherical shape, diameter 3~5mm) simultaneously; Add 8.31mL (0.12mol) of acrylic acid in a continuous dropwise manner, and the dropwise addition is completed within 1.5 hours; at the same time, add 5.43g of catalyst p-aminobenzenesulfonic acid and 0.009g of polymerization inhibitor hydroquinone, and carry out esterification reaction at 95°C , After 5h, polyoxyethylene allyl ester (PA) was obtained.

[0048] The second step, polymerization reaction: add 19.08g (0.12mol) MAS and appropriate amount of distilled water in the 1000mL four-necked flask that brea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com