Three-dimensional multicolor dry-grain polished ceramic large plate and preparation method thereof

A dry particle, ceramic technology, applied in the field of architectural ceramics, can solve the problems of pore defects, unevenness, exposed glaze, etc., and achieve excellent three-dimensional effect and high brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] A method for preparing a three-dimensional illusion dry grain polished ceramic slab, comprising the following steps:

[0048] (1) Green body preparation: the colored powder obtained by dry-mixing the powder and the color material is matched with the multi-tube material distribution equipment formed by the press to form the designed pattern, and pressed into the whole body brick to obtain the green body layer;

[0049] (2) Bottom glaze spraying: After the body is dried, it is sprayed with bottom glaze to form a bottom glaze layer;

[0050] (3) Inkjet treatment: Carry out inkjet decoration treatment on the bottom glaze layer according to the designed pattern to form an inkjet printing layer;

[0051] (4) Colloidal particle protective layer spraying treatment: According to the parts by weight, take 100 parts of ceramic glue and 20-40 parts of fine powder dry particles to mix and compound to obtain modified ceramic glue, and spray the modified ceramic glue on the surface of t...

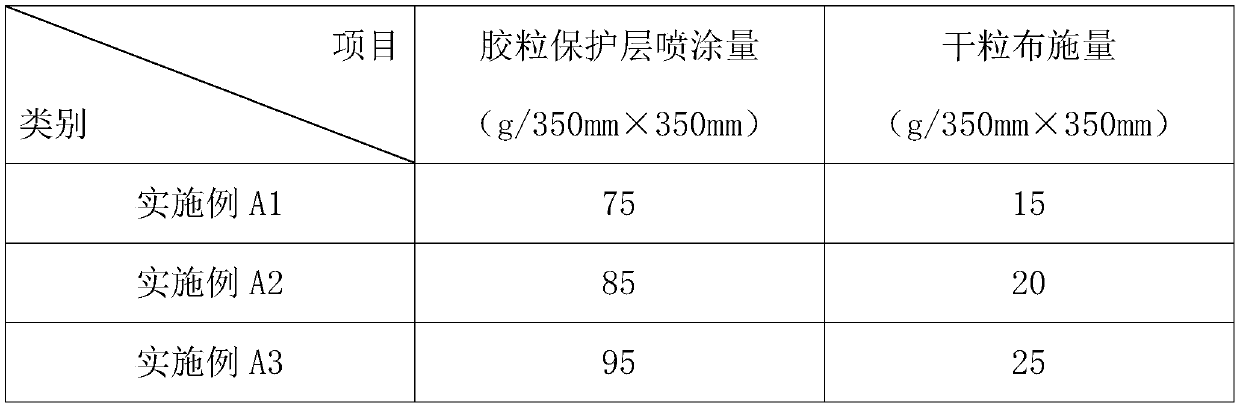

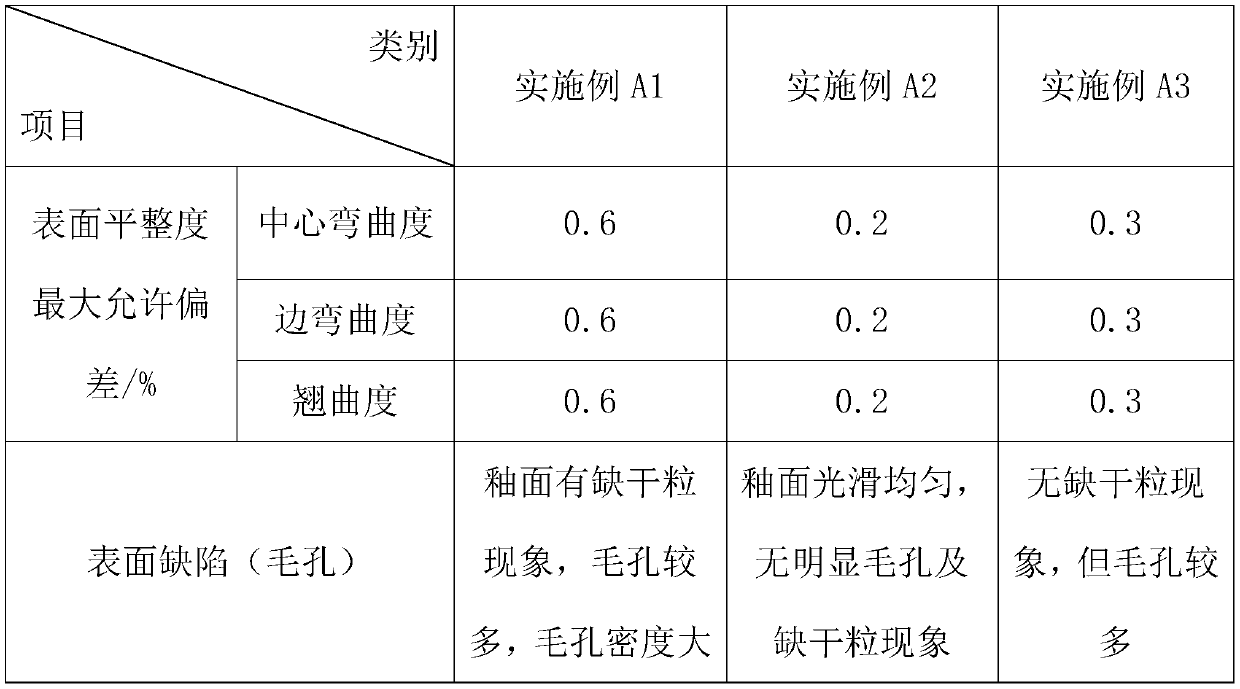

Embodiment A

[0062] A three-dimensional illusion color dry grain polished ceramic slab is prepared according to the following steps:

[0063] (1) Green body preparation: Add the raw material components of the green body into a ball mill to mix and ball-mill to obtain a slurry. After the slurry is sieved, stale, and impurity-removed, it is spray-dried to obtain a powder, and then the powder and the color are dried. The color mixing equipment is used for color mixing, and the obtained colored powder is matched with the multi-tube material distribution equipment formed by the press to form the designed pattern, and pressed into the whole brick adobe to obtain the adobe layer;

[0064] Among them, the green body raw materials include 36% weathered aluminum sand, 30% potassium sodium sand, 5% magnesia soil, 10% black mud, 9% bentonite, 8% edging slag and 2% polishing slag, and add 0.5% degumming agent, 0.4% water glass and 0.1% PVA;

[0065] (2) Bottom glaze spraying treatment: Put the raw mat...

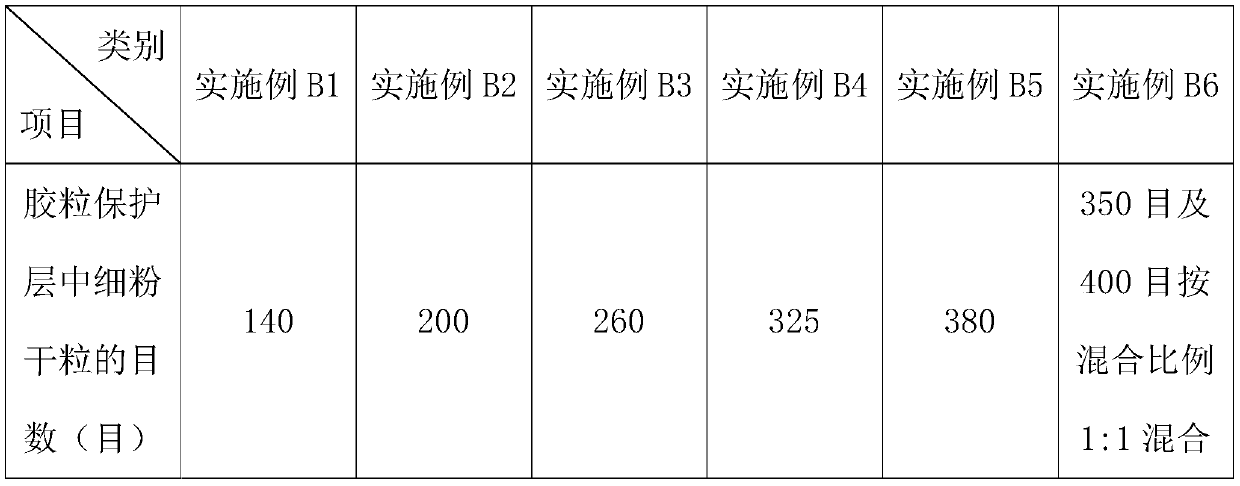

Embodiment B

[0078] A three-dimensional illusion color dry grain polished ceramic slab is prepared according to the following steps:

[0079] (1) Green body preparation: Add the raw material components of the green body into a ball mill to mix and ball-mill to obtain a slurry. After the slurry is sieved, stale, and impurity-removed, it is spray-dried to obtain a powder, and then the powder and the color are dried. The color mixing equipment is used for color mixing, and the obtained colored powder is matched with the multi-tube material distribution equipment formed by the press to form the designed pattern, and pressed into the whole brick adobe to obtain the adobe layer;

[0080] Among them, the green body raw materials include 36% weathered aluminum sand, 30% potassium sodium sand, 5% magnesia soil, 10% black mud, 9% bentonite, 8% edging slag and 2% polishing slag, and add 0.5% degumming agent, 0.4% water glass and 0.1% PVA;

[0081] (2) Bottom glaze spraying treatment: Put the raw mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com