Stereograph and making method thereof

A production method and technology of three-dimensional pictures, which are applied in the direction of imitating three-dimensional effect patterns, special patterns, decorative arts, etc., can solve the problems of poor weather resistance, narrow viewing angle, low pattern definition, etc., and achieve high ornamental and artistic value, The production method is simple and the three-dimensional effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

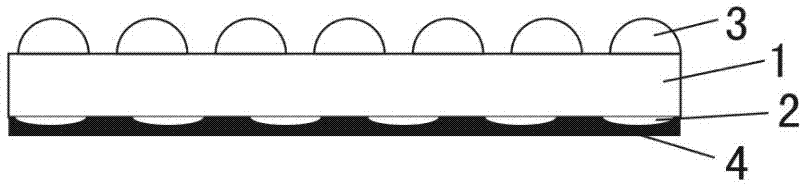

[0025] Embodiment 1: as figure 1 As shown, a three-dimensional picture includes a glass substrate 1, one side of the glass substrate 1 is a grating layer 3, and the other side of the glass substrate 1 is provided with a grating image 2. A protective layer 4 is provided on the surface of the grating image 2 . The grating layer 3 is a lattice grating, which is composed of a cylindrical dot array with a height greater than or equal to 0.1 μm.

[0026] The making method of making described three-dimensional picture, comprises the steps:

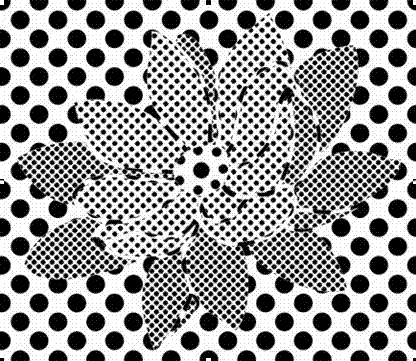

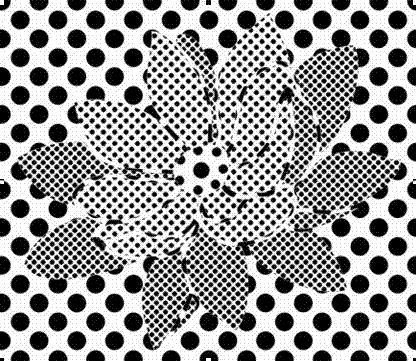

[0027] (1) Perform rasterization processing on the planar image to obtain a raster image; specifically: divide the two-dimensional scene in the planar image into different effect units according to the real scene; each effect unit is composed of small patterns arranged in a dot matrix on a microscopic level, The specifications of the small patterns in the same effect unit are the same, and the specifications of the small patterns in different e...

Embodiment 2

[0030] Embodiment 2: as figure 1 As shown, a three-dimensional picture includes a glass substrate 1, one side of the glass substrate 1 is a grating layer 3, and the other side of the glass substrate 1 is provided with a grating image 2. A protective layer 4 is provided on the surface of the grating image 2 . The grating layer 3 is a lattice grating, which is composed of a dot array of a spherical arc surface with a height of 1 μm to 200 μm.

[0031] The making method of making described three-dimensional picture, comprises the steps:

[0032] (1) Perform rasterization processing on the planar image to obtain a raster image; specifically: divide the two-dimensional scene in the planar image into different effect units according to the real scene; each effect unit is composed of small patterns arranged in a dot matrix on a microscopic level, The specifications of the small patterns in the same effect unit are the same, and the specifications of the small patterns in different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com