Manufacturing method of container and container manufactured by utilizing method

A manufacturing method and container technology, which can be applied to containers, thermal insulation containers, applications, etc., can solve the problems of inability to achieve printing quality, poor printing, and inability to highlight the advantages of a three-dimensional foam layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

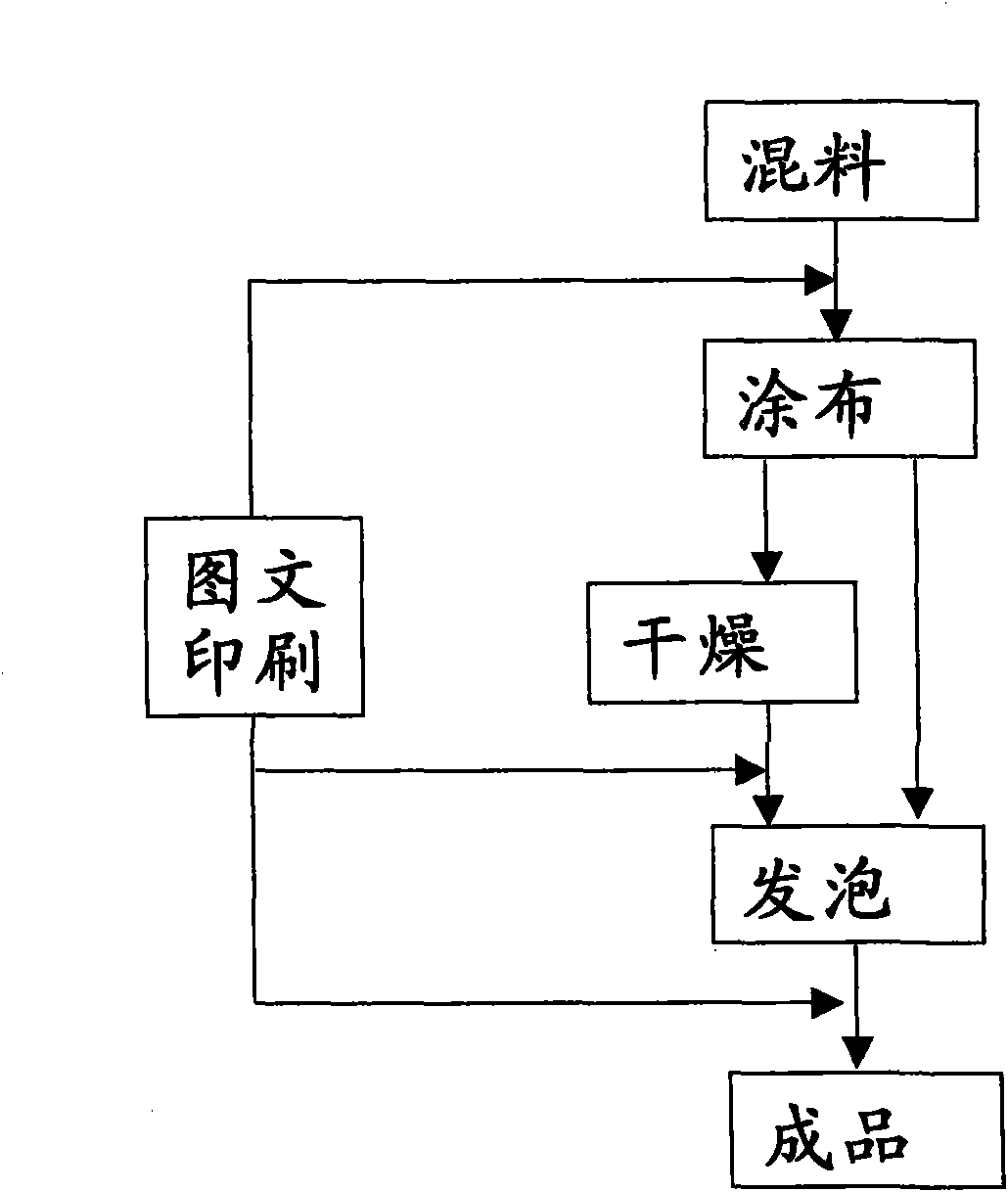

[0022] First, please refer to figure 1 , in the present invention, the manufacturing method of this container comprises the following steps:

[0023] Mixing: Stir and mix the liquid adhesive with the thermally expanded particle powder formed by coating the low-boiling point solvent in the thermoplastic polymer to form a composite coating; the liquid adhesive is selected from polyvinyl acetate, ethylene-vinyl acetate One of the group consisting of , polyurethane and mixtures thereof, the liquid adhesive can be water-based or oil-based;

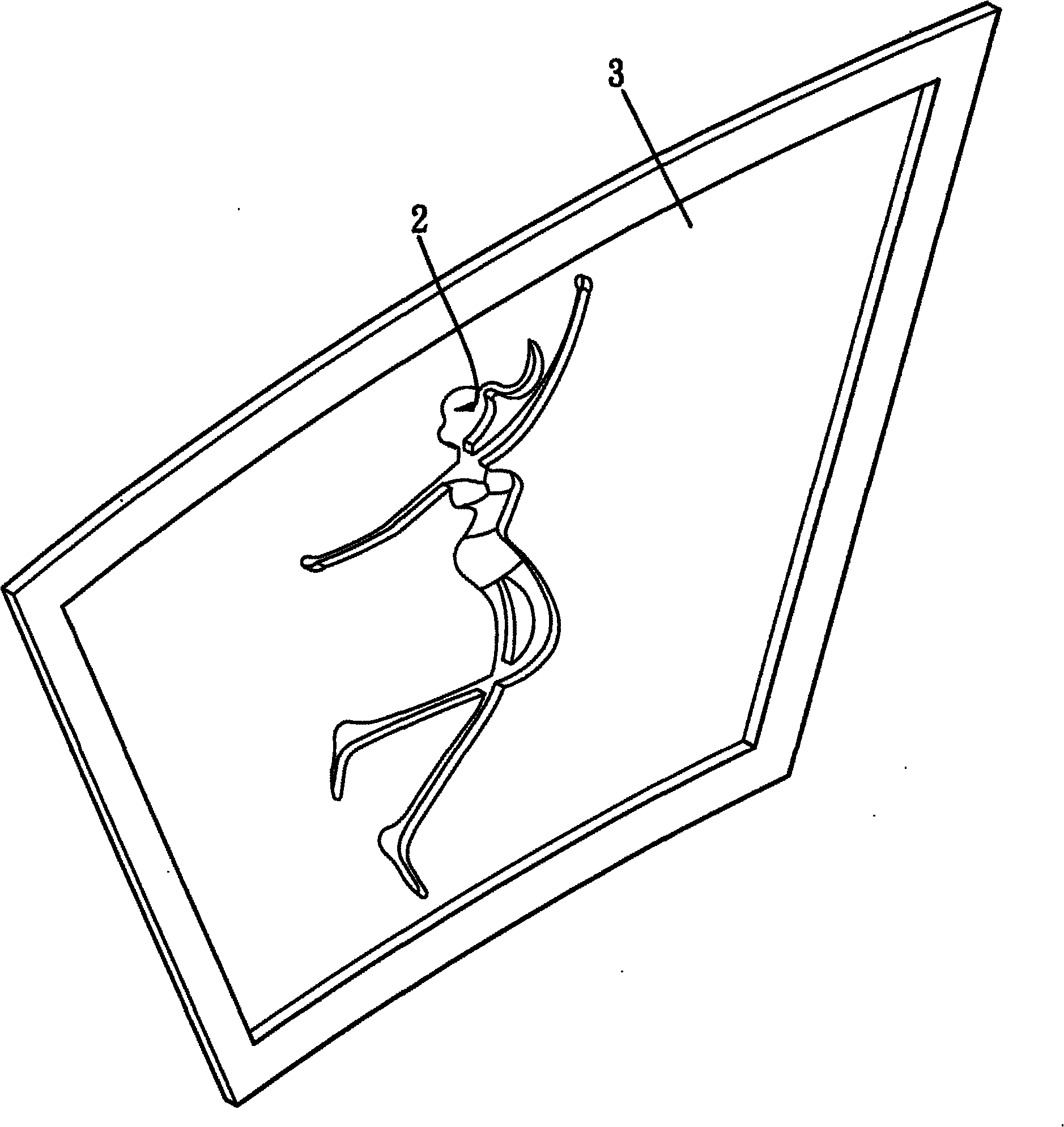

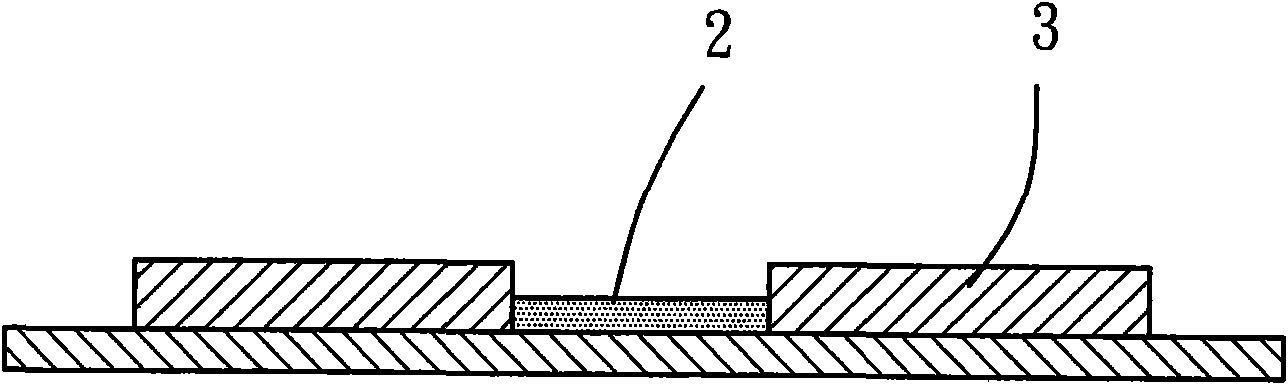

[0024] Coating: the composite coating is directly coated on the outer surface of a substrate of a container, and the composite coating is surrounded by at least one hollowed out part that is not coated with the composite coating; Finished containers or semi-finished containers that have not yet been formed. The above-mentioned finished containers are, for example, paper or plastic cups, bowls, plates, or other containers made of such materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com