Machine tool

A technology for machine tools and objects, applied in computer control, metal processing mechanical parts, large fixed members, etc., can solve problems such as spindle tilting to one side, unsatisfactory accuracy level of processed workpieces, etc., to prevent the reduction of processing accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

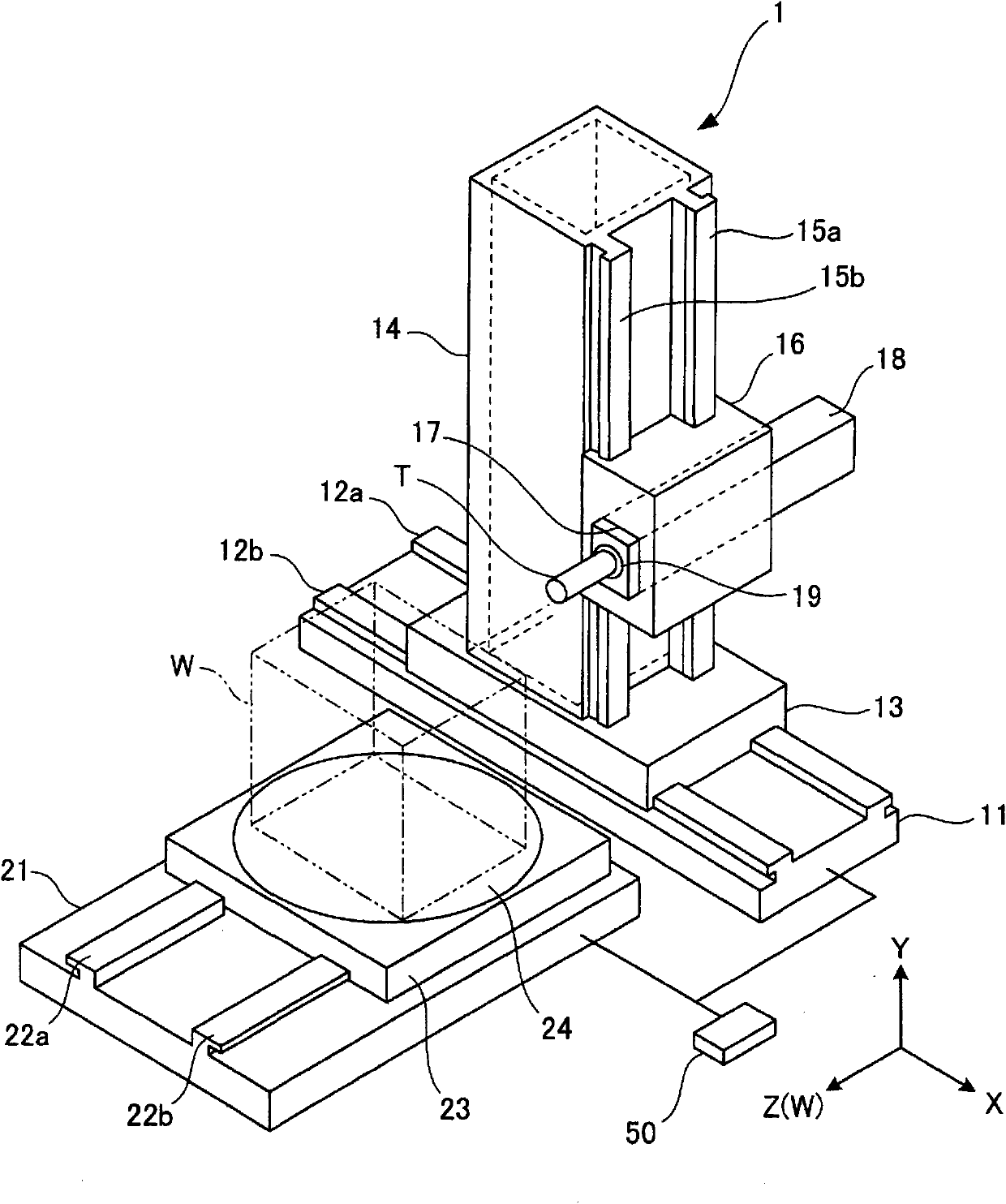

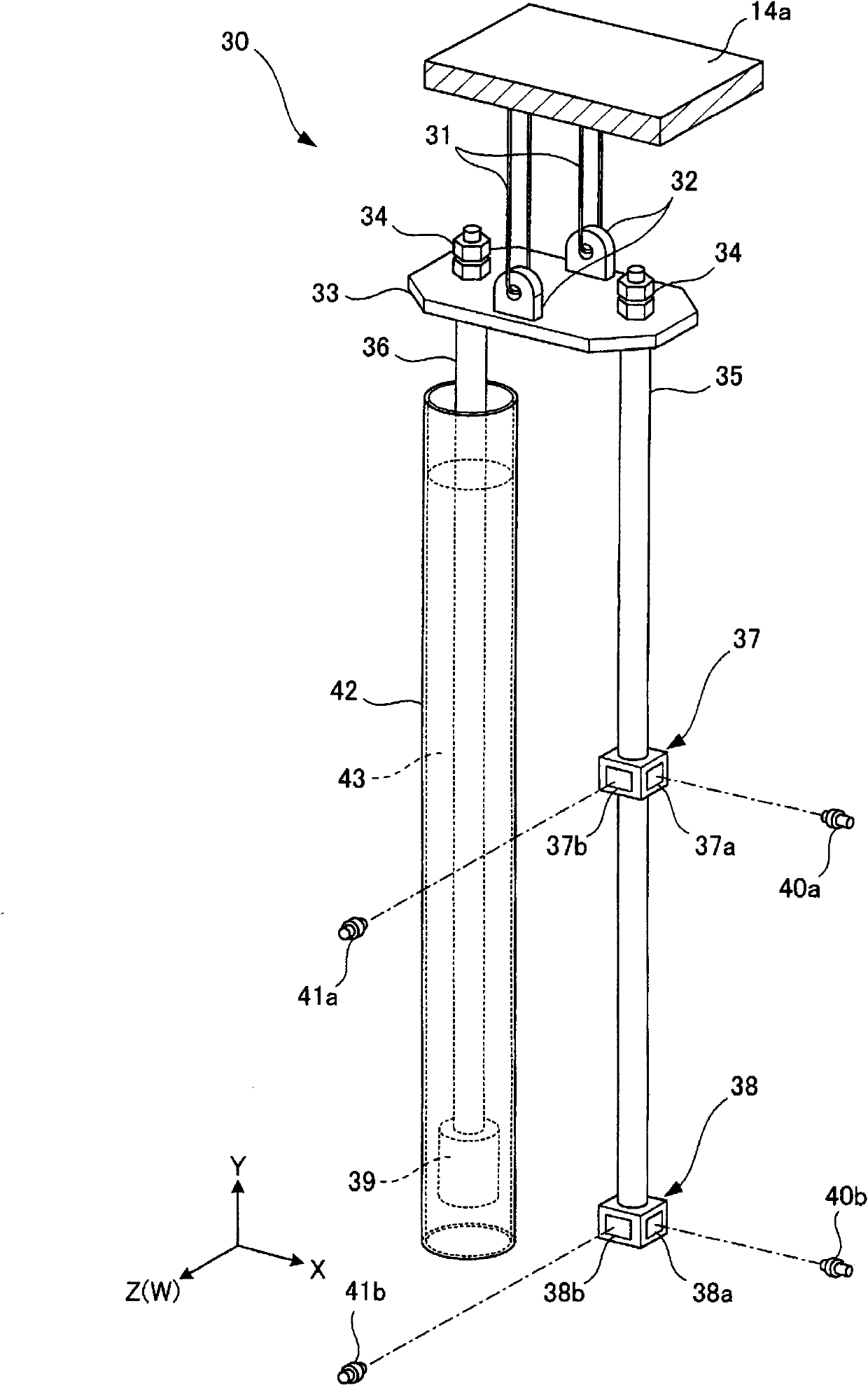

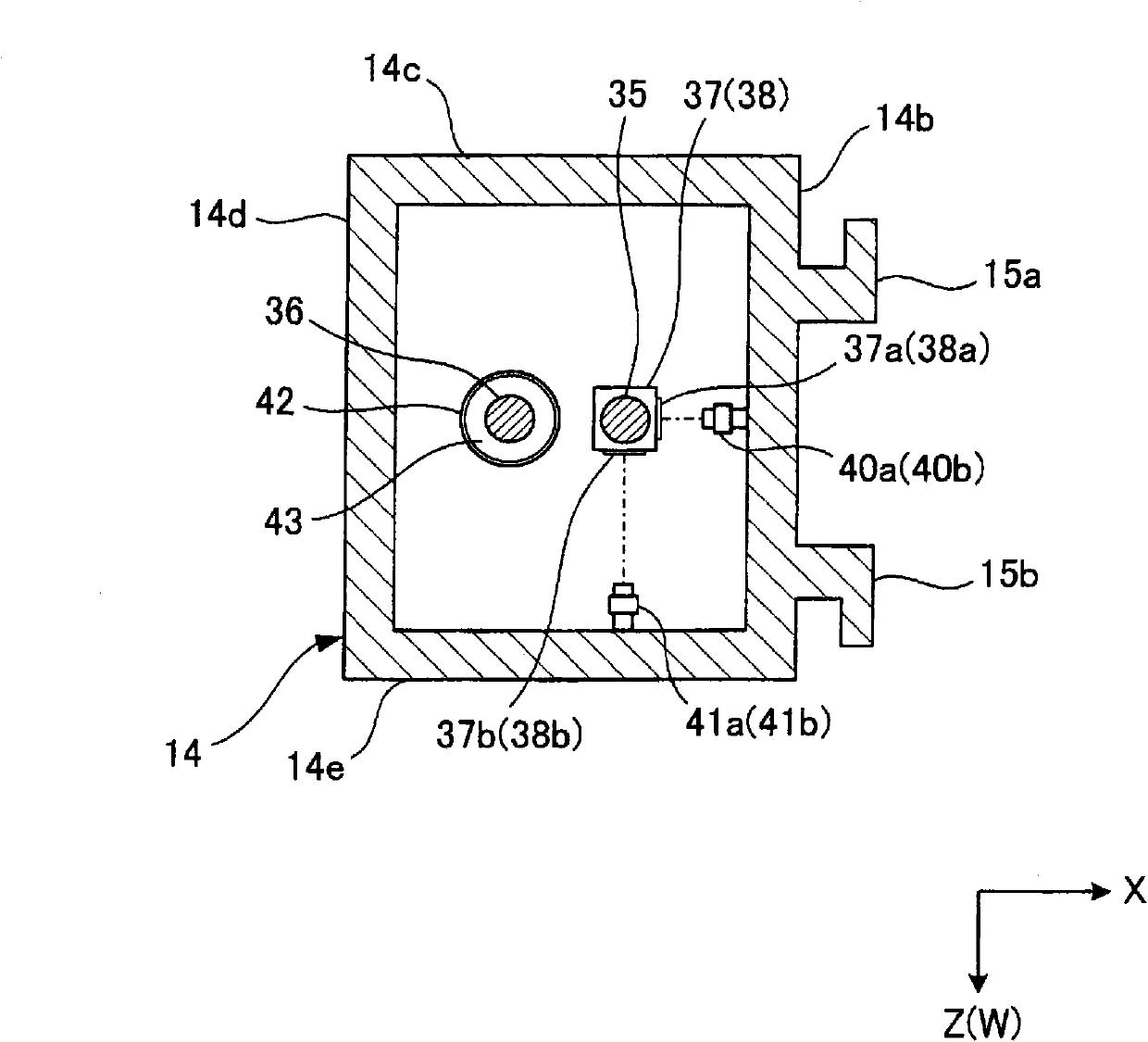

[0048] A machine tool according to an embodiment of the present invention will be described in detail below with reference to the accompanying drawings. figure 1 is a schematic perspective view of a machine tool according to an embodiment of the present invention. figure 2 is an overall configuration diagram illustrating the column deformation detection equipment. image 3 is the cross-sectional view of the column. Figure 4 is a schematic diagram illustrating how the column deforms along the X-axis. Figure 5 is a schematic diagram showing how the column deforms along the Z-axis. In each drawing, directions indicated by X, Y, and Z(W) represent orthogonal three-axis directions, which are orthogonal to each other, and specifically, respectively represent front-rear directions, The vertical direction of the machine tool and the width direction of the machine tool. In addition, an embodiment to be described below is an application of the machine tool according to the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com