Rubber cutting machine capable of carrying out precise machining

A technology of precision processing and rubber cutting machine, which is applied in metal processing and other directions, and can solve problems such as difficulty in guaranteeing rubber cutting accuracy, obstruction of staff, and large manual operation errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

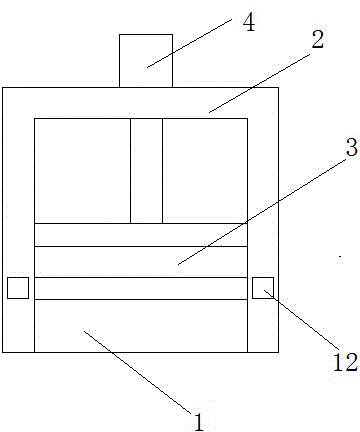

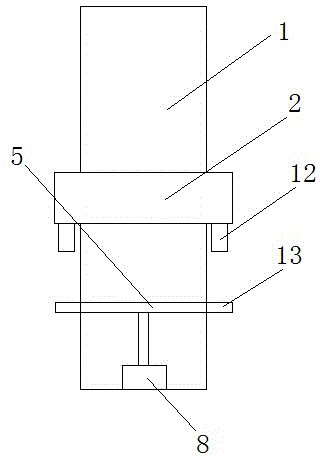

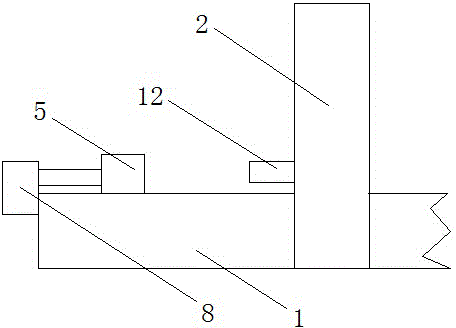

[0023] Such as figure 1 , figure 2 and image 3 A rubber cutting machine capable of precise processing is shown, which includes a rubber guide seat 1 for placing rubber, a frame 2 is arranged in the rubber guide seat, and the opposite end faces of the frame 2 and the rubber guide seat 1 are provided with The rubber cutting knife 3 is controlled by the hydraulic cylinder 4 arranged on the upper end of the frame; in the rubber cutting machine capable of precise processing, the end of the rubber guide seat 1 is vertical to the rubber cutting knife 3 A baffle 5 is provided between the planes; a slide rail 6 is provided at the junction of the upper end surface and the side end surface of the rubber guide seat 1 , and the baffle 5 extends to the inside of the slide rail.

[0024] As an improvement of the present invention, such as Figure 4 As shown, the two ends of the lower end of the baffle plate 5 are provided with pulleys 7 extending to the inside of the slide rail 6 ; the ...

Embodiment 2

[0031] As an improvement of the present invention, two laser range finders 12 are arranged in the frame 2, which are respectively arranged in the frame 2, and are located on the outer parts of the two sides of the side end surface of the rubber guide seat 1; The side end surface of the plate 5 is provided with a distance measuring plate 13 extending vertically outside the side end surface along the length direction of the baffle plate. An electrical connection is adopted between the range finder 12 and the pneumatic cylinder 8 . With the above design, it can make the laser rangefinder effectively measure the distance between the baffle and the frame, and through the pneumatic cylinder electrically connected to it, the baffle can be accurately positioned to the required processing distance, thereby further improving the processing accuracy; At the same time, the above solution avoids the impact on rubber transmission by setting the laser range finder outside the rubber guide se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com