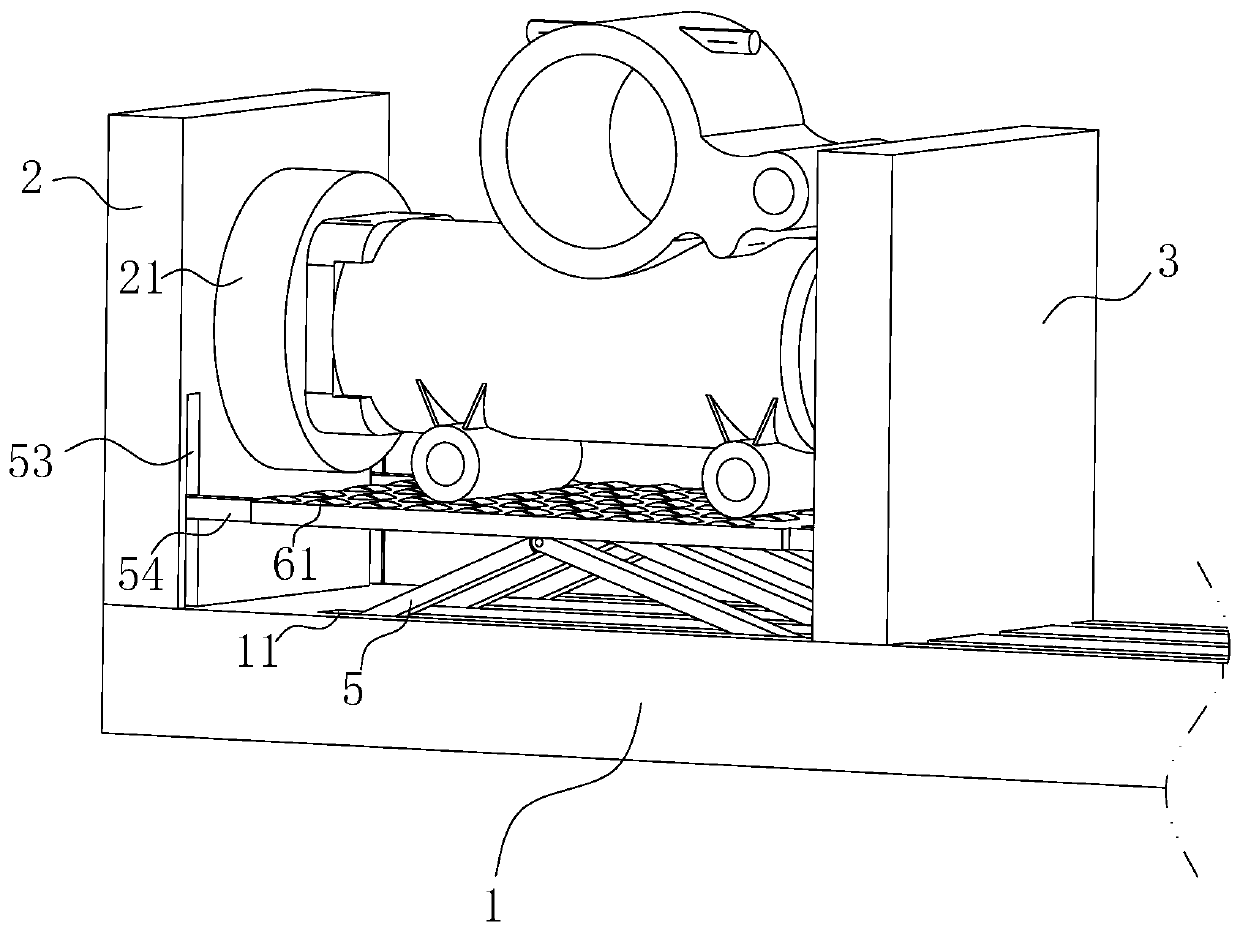

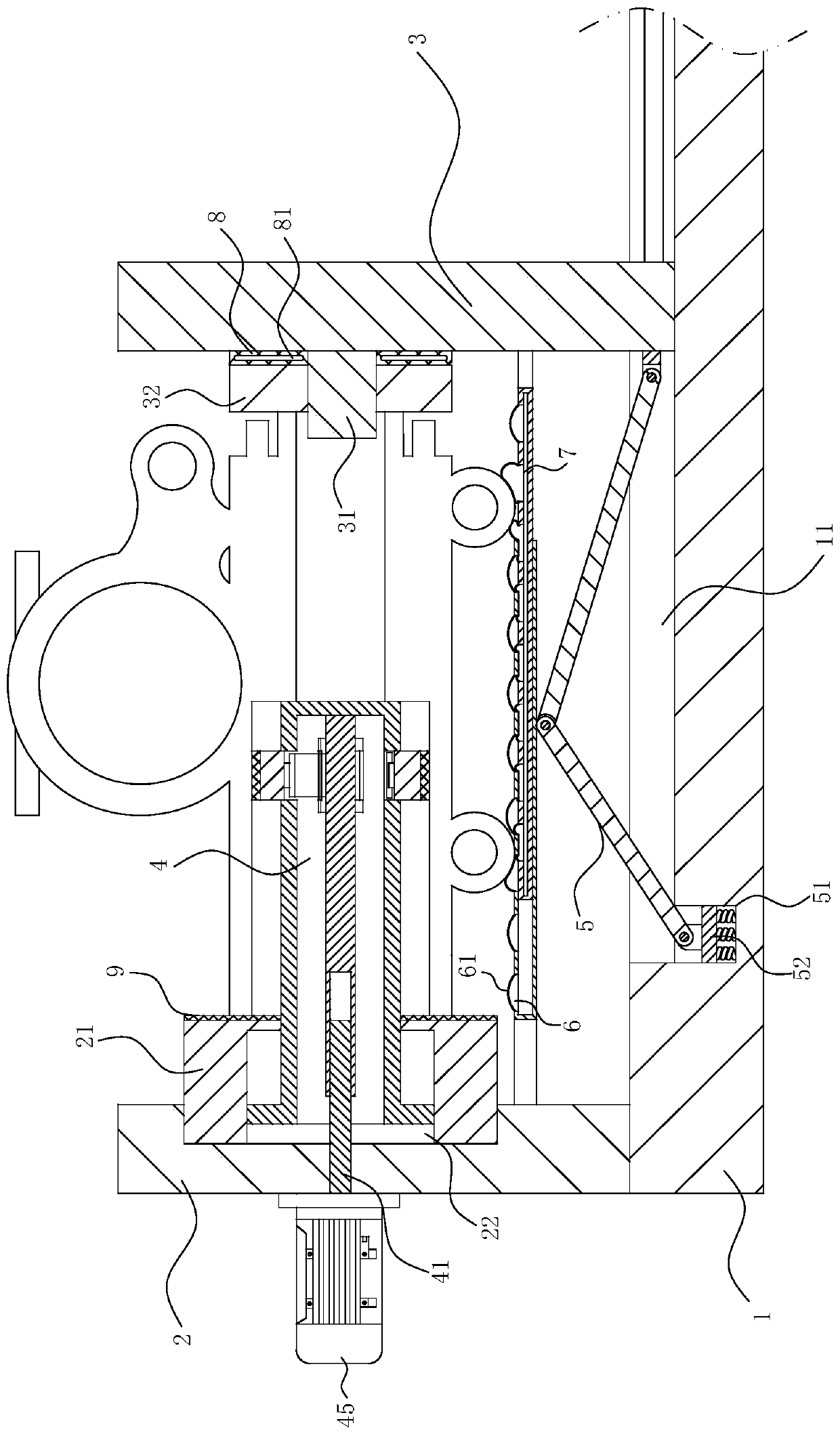

Automobile steering machine shell arm hole boring fixture

A steering gear and housing technology, which is used in clamping, manufacturing tools, drilling/drilling equipment, etc., can solve the problems of insufficient tightening of fixtures and different specifications of steering gear housings, so as to improve quality and enhance tightness. Solid effect and damage avoidance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

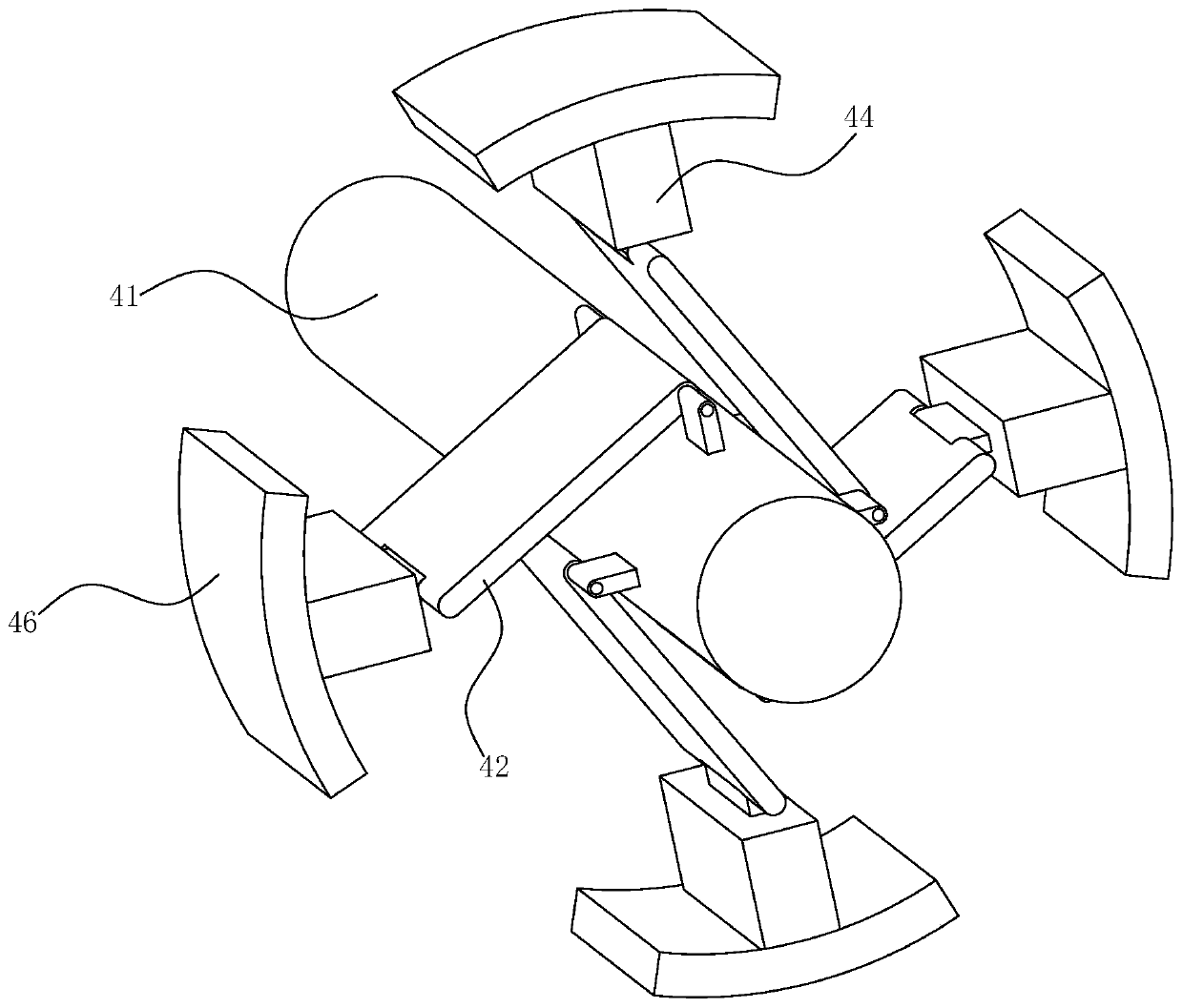

[0023] As an embodiment of the present invention, the sliding block 44 is fixedly connected with a rubber pad 46 on the outer surface of the positioning column 23; a reinforcing rod 47 is evenly arranged inside the rubber pad 46; the reinforcing rod 47 has two guide rods When working, the motor 45 rotates so that the hinge plate 42 pushes the sliding block 44 to squeeze the inner wall of the steering machine housing, and then fixes the steering machine housing. Outside the third chute 43 of the sliding block 44 When the displacement occurs, the rubber pad 46 fixed on the surface of the sliding block 44 first contacts the inner wall of the through hole of the steering gear housing. At the same time, with the continuous displacement of the sliding block 44, pressure is gradually exerted on the rubber pad 46. 47 first generates pressure with the inner wall of the through hole of the steering machine housing, and as the pressure increases, the reinforcing rod 47 gradually rotates a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com