Fine-processing rice shelling equipment

A technology of fine processing and paddy, applied in grain hulling, grain processing, grain pod removal, etc., can solve the problems of low processing precision, inability to completely separate rice and rice bran, and doping, etc., to improve processing precision and facilitate thorough The effect of separation work, improving the speed of separation and the quality of discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

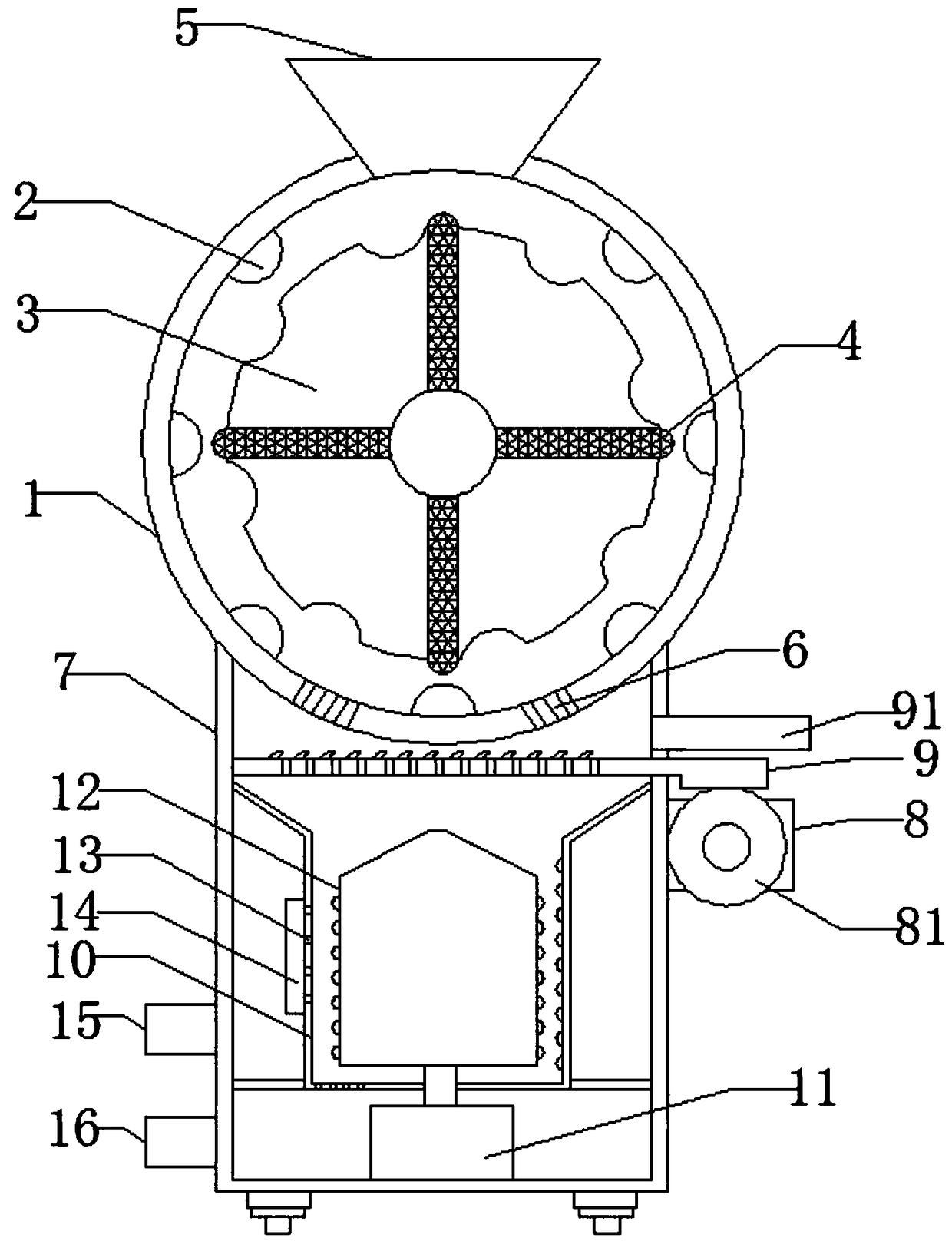

[0017] See Figure 1-2 This embodiment provides a finely processed rice dehulling equipment, which includes a dehulling cylinder 1. The inner side of the dehulling cylinder 1 is fixedly connected with a number of protrusions 2, and the middle of the dehulling cylinder 1 is rotatably connected with a rotating roller 3, which rotates The side of the roller 3 is fixedly installed with a cutter head 4, the upper end of the shelling cylinder 1 is provided with a feed port 5, a number of first through holes 6 are opened under the shelling cylinder 1, and the lower end of the shelling cylinder 1 is fixedly connected with a box body 7. A first motor 8 is fixedly installed at the right end of the body 7, the output shaft of the first motor 8 is connected with a shelling plate 9, and the shelling plate 9 slides through the box body 7, and a first rice bran outlet 91 is opened above the right end of the box body 7. The box body 7 is fixedly connected with a fixed frame 10, the lower end o...

Embodiment 2

[0020] See Figure 1-2 , A further improvement is made on the basis of the first embodiment: the output shaft of the first motor 8 is fixedly connected with a gear 81, and the side of the gear 81 is slidably connected with a shelling plate 9. The upper end of the hulling plate 9 is fixedly connected with a number of teeth, and the hulling plate 9 is provided with drop holes. The first motor 8 is used to drive the hulling plate 9 to move through a gear 81, and then the teeth are used to remove the rice bran from the first rice bran. The outlet 91 is discharged, and the millet falls into the fixed frame 10 from the drop hole.

[0021] Among them, the left side of the fixed frame 10 is provided with a number of second through holes 13, and the left end of the fixed frame 10 is fixedly installed with an axial fan 14. The model of the axial fan 14 is T35-11, and the output end of the axial fan 14 is connected to the second Corresponding to the hole 13, after being hulled again by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com