Rotary index device in machine tool

A technology for working machines and indexing devices, which is applied to metal processing machinery parts, mechanical equipment, manufacturing tools, etc., can solve problems such as the reduction of machining accuracy, and achieve the effect of preventing the reduction of machining accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

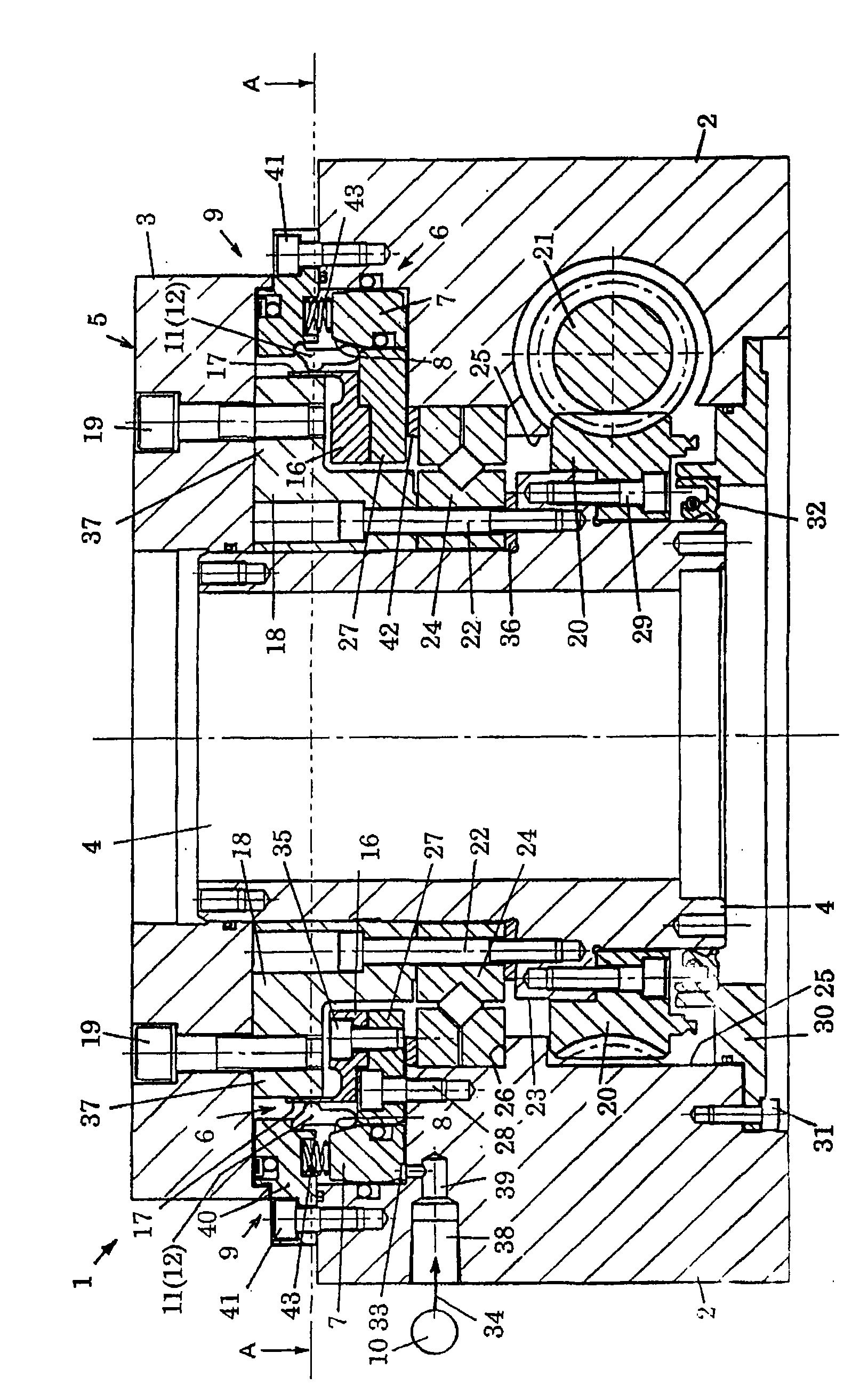

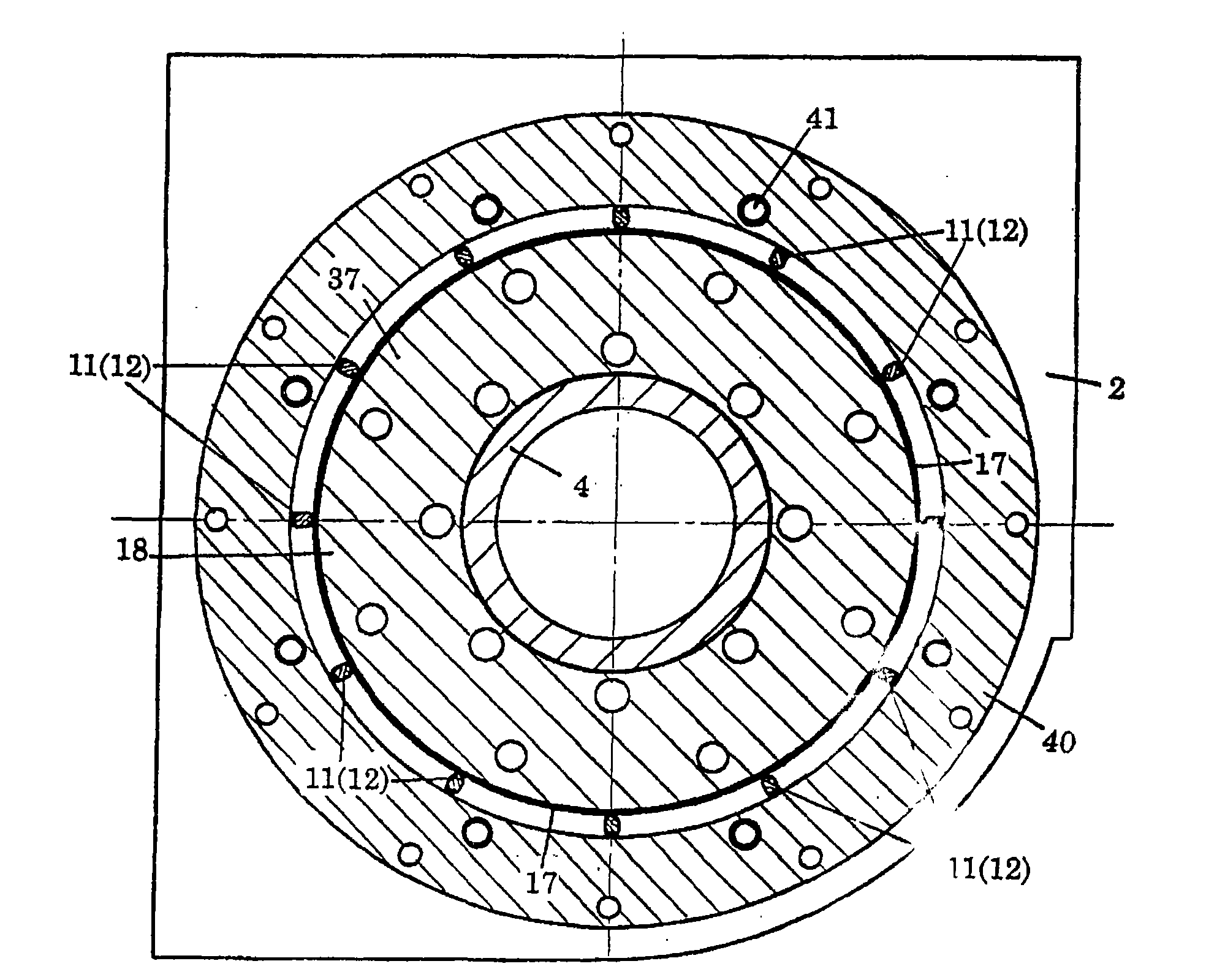

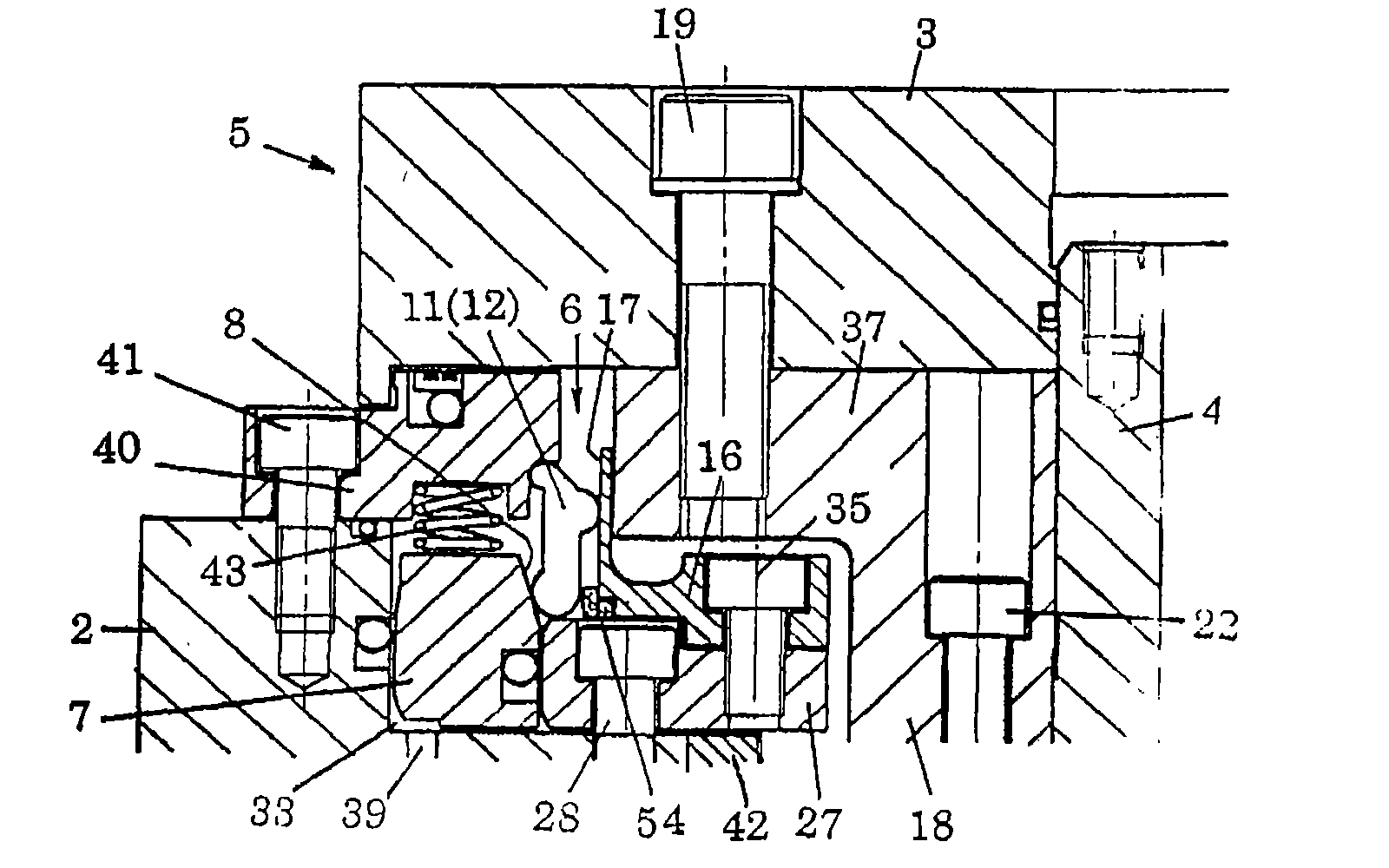

[0062] 1 to 4 show typical examples of applying the rotary indexing device 1 for machine tools according to the present invention to a rotary table device. In these Figures 1 to 4, the rotary indexing device 1 of a working machine includes: a rotary shaft 4 freely rotatably provided in a casing 2, a rotary body 5 including this rotary shaft 4, and a The clamping device 6 acts on the body 5 in the radial direction of the rotating shaft 4 and maintains the indexed rotational angle position of the rotating body 5 .

[0063] The rotating shaft 4 is, for example, a hollow body rotatably provided inside the receiving hole 25 of the casing 2, and the circular table 3 as a member to be driven to rotate is attached relatively non-rotatably to the end thereof. This round table 3 is arranged parallel to one surface of the block-shaped casing 2, and is fitted to the rotating shaft 4 at the central hole portion, and is fixed to a part of the rotating body 5 by a plurality of mounting bolts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com