Flattening method and flattening apparatus

a flattening apparatus and flattening method technology, applied in the direction of lapping tools, semiconductor devices, decorative arts, etc., can solve the problems of high-throughput processing difficulty with the care method, significantly low processing rate as compared to grinding, cmp, etc., and achieve high precision, sufficient processing rate, and enhance the effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

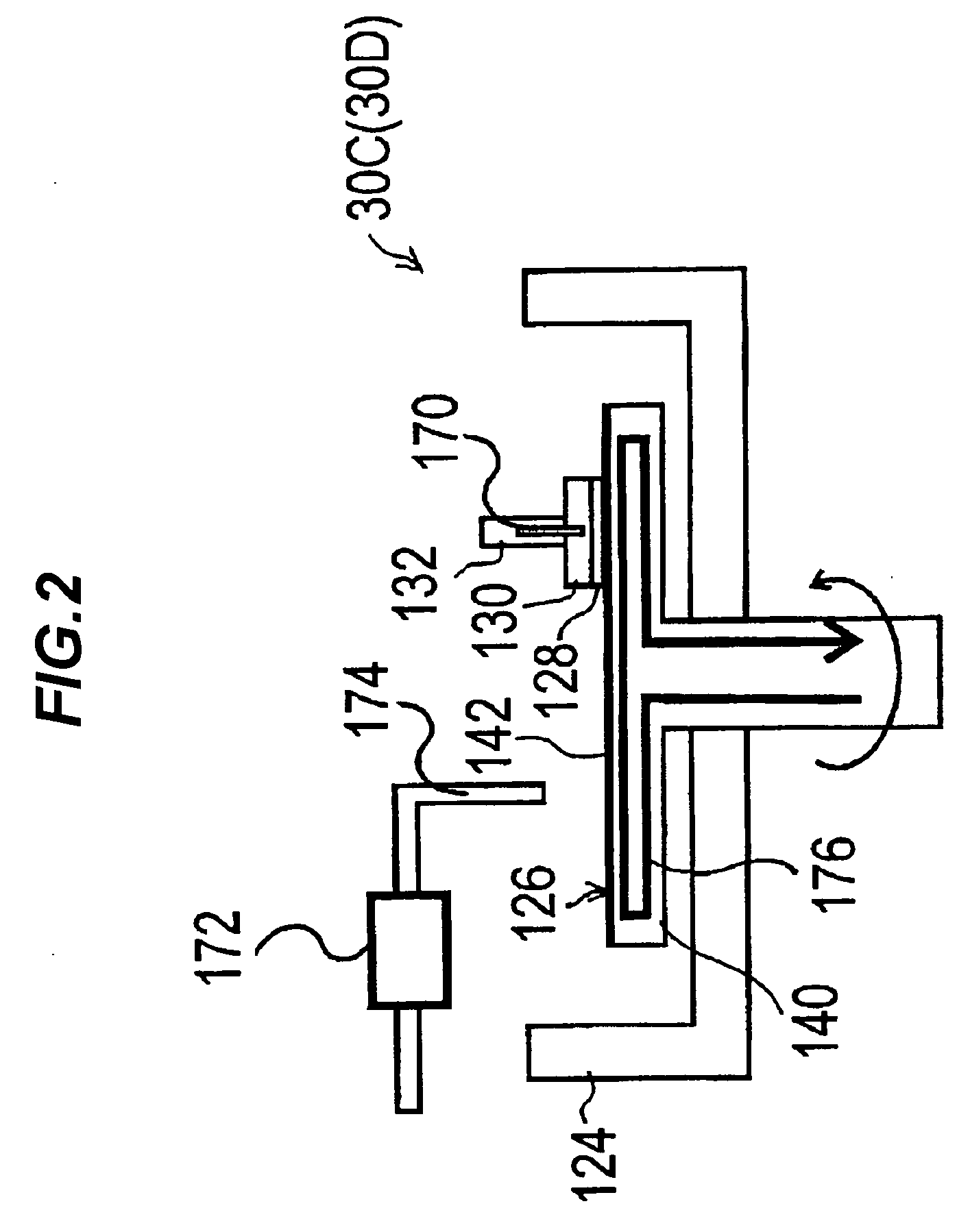

[0053]Preferred embodiments of the present invention will now be described with reference to the drawings. The following description illustrates the case of using hydrofluoric acid (HF) as a processing solution and platinum as a catalyst, and processing and removing a surface (surface to be processed) of a substrate, such as an SiC wafer, into a desired flatness.

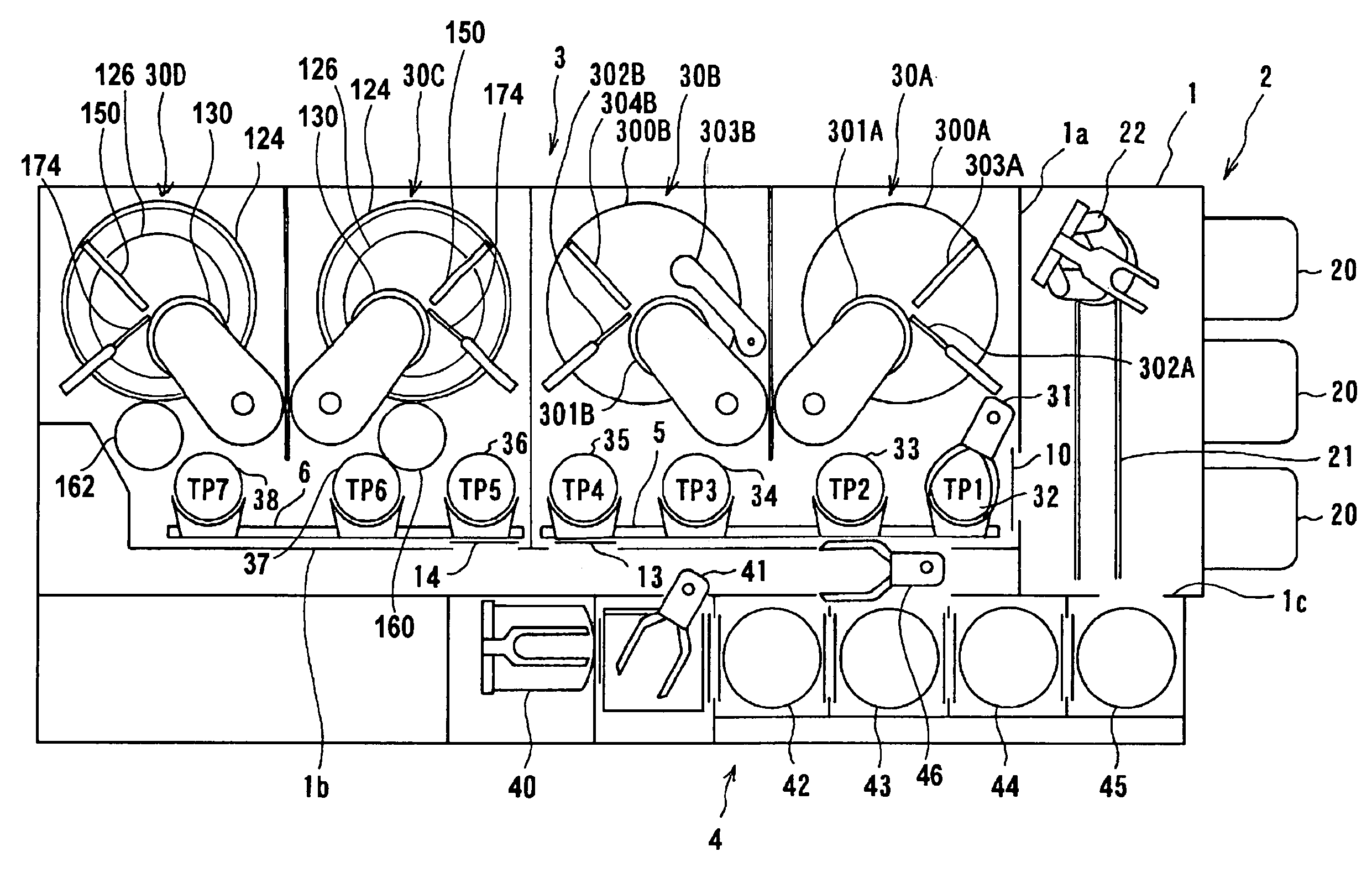

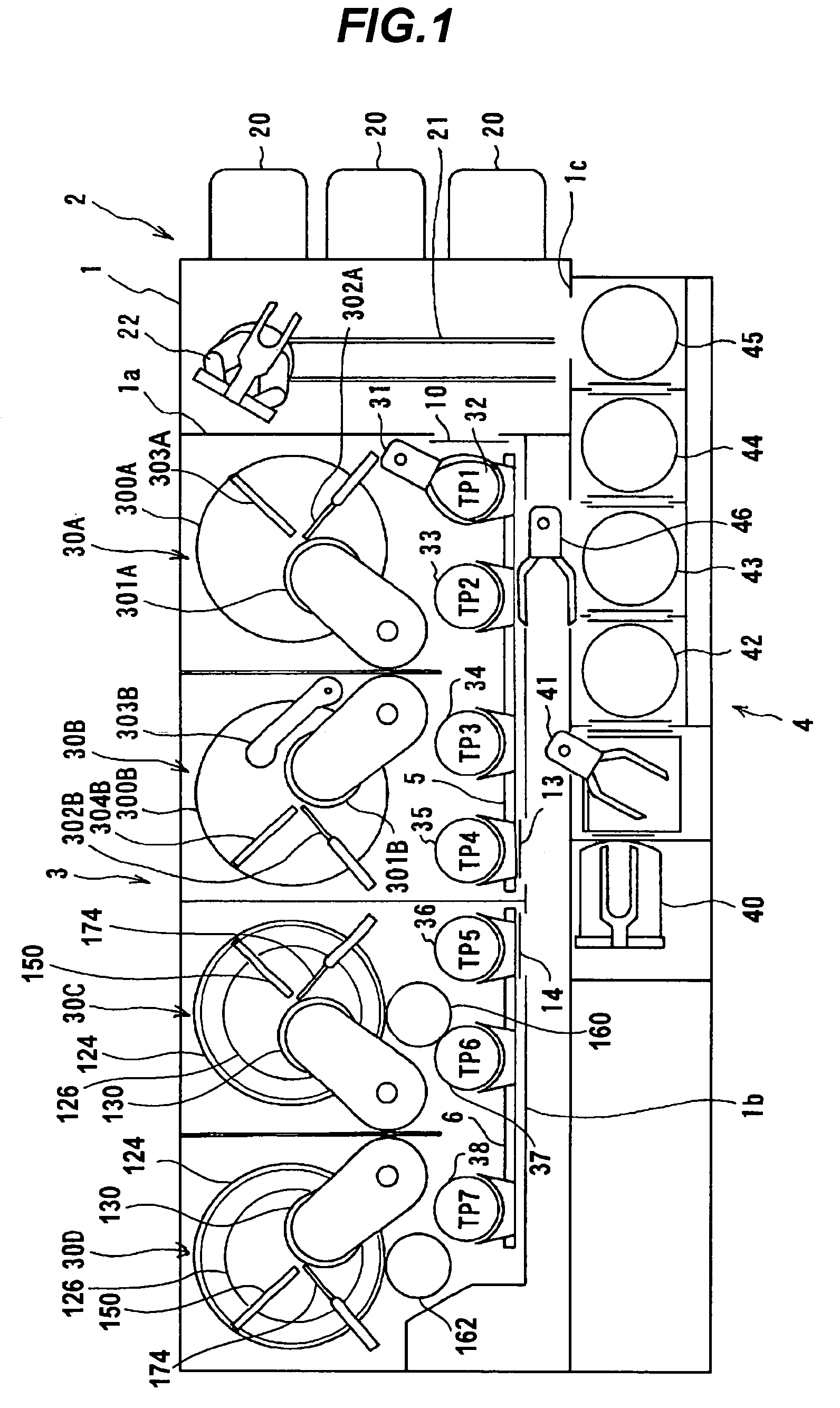

[0054]FIG. 1 is a plan view showing the overall construction of a flattening apparatus according to an embodiment of the present invention. As shown in FIG. 1, the flattening apparatus of this embodiment includes a generally rectangular housing 1 whose interior is divided by partition walls 1a, 1b, 1c into a loading / unloading section 2, a surface removal processing section 3 and a cleaning section 4. The loading / unloading section 2, the surface removal processing section 3 and the cleaning section 4 are independently fabricated and independently ventilated.

[0055]The loading / unloading section 2 includes at least two (three in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| groove depth | aaaaa | aaaaa |

| groove depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com