Internal gear-wheel pump comprising reinforced channels

a gear wheel and channel technology, applied in the direction of pump components, positive displacement liquid engines, rotary piston liquid engines, etc., can solve the problems of affecting the stability of the housing, high cost of known fuel pumps, etc., and achieve the effect of low strength and particularly cost-effective production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

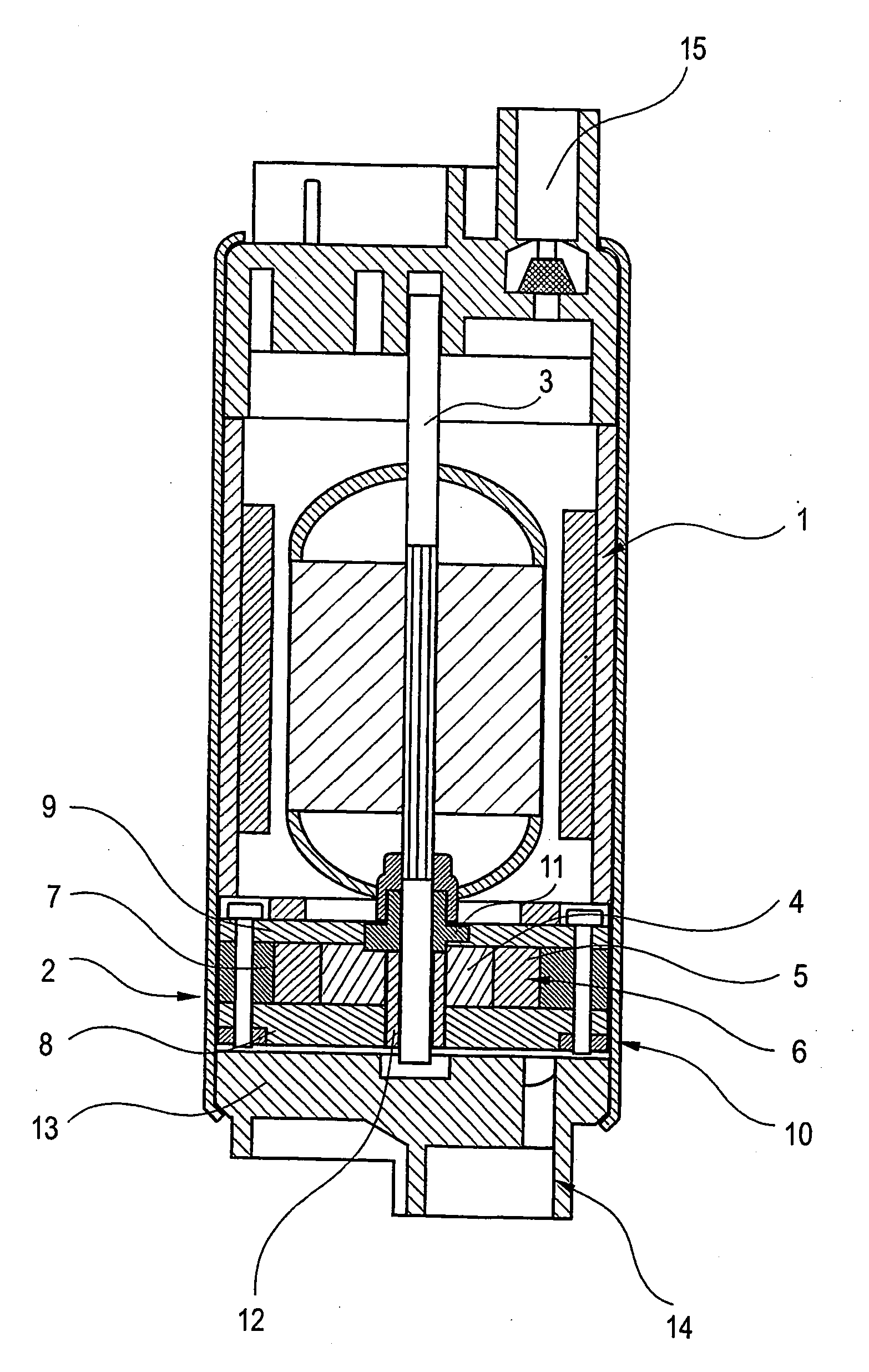

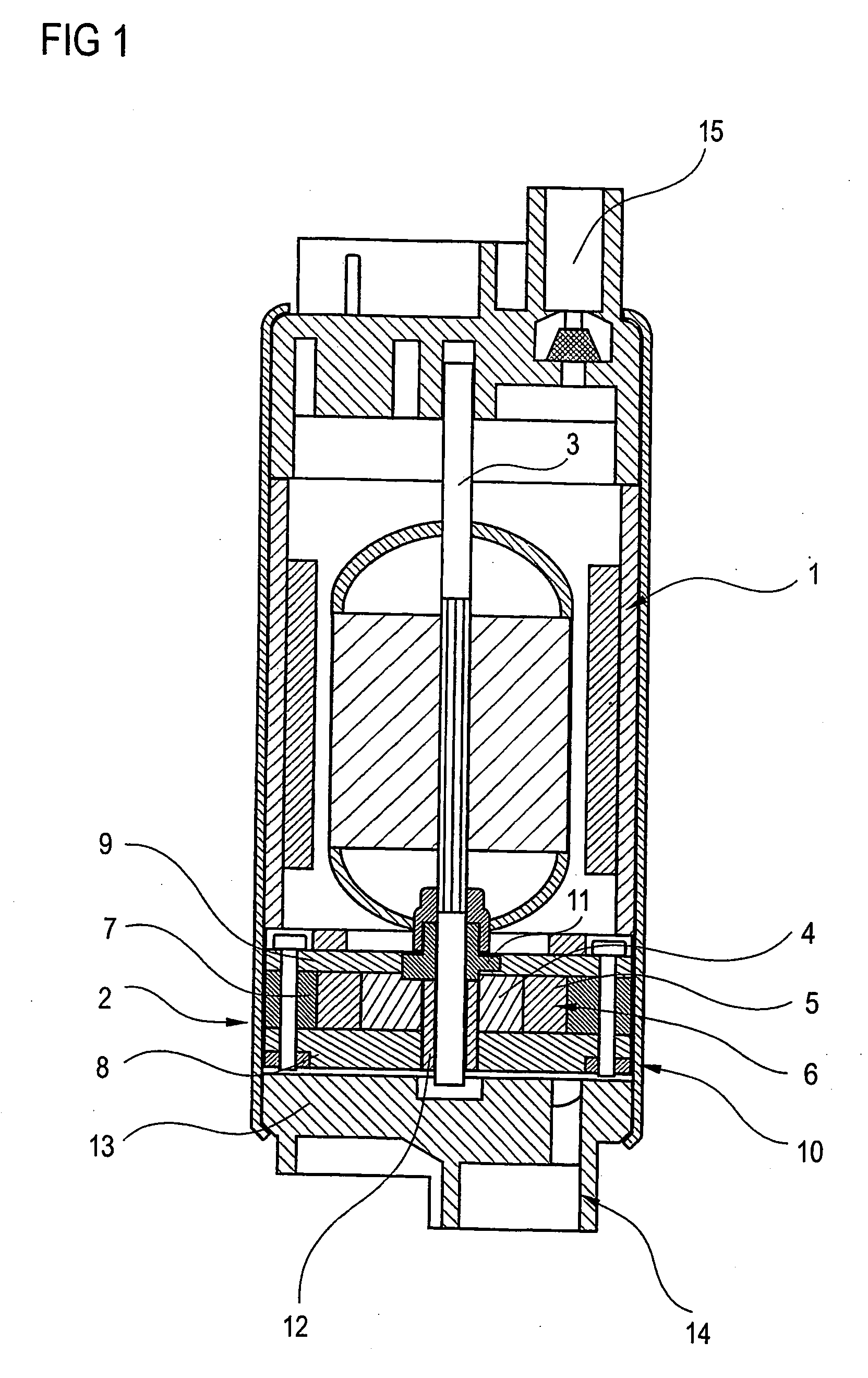

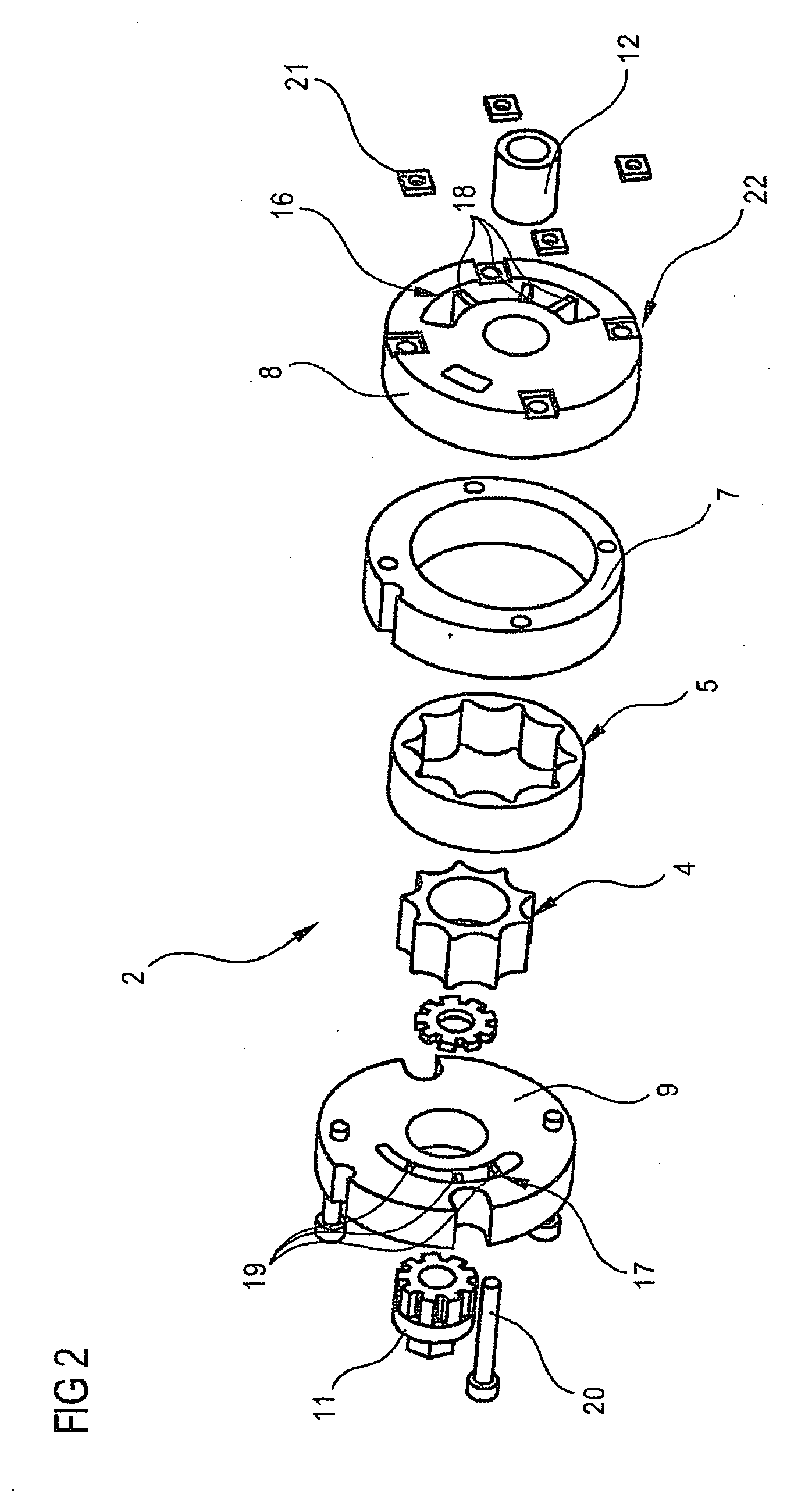

[0014]FIG. 1 shows a section illustration through a feed unit for feeding diesel fuel from a fuel tank (not illustrated) of a motor vehicle to an internal combustion engine having a fuel pump 2 which is driven by an electric motor 1. The fuel pump 2 has an inner rotor 4 which is connected to a shaft 3 of the electric motor 1 and forms a rotor pair 6 with an outer rotor 5. The outer rotor 5 is mounted radially in an annular element 7 and axially between two housing parts 8, 9 of a housing 10. A coupling 11 is arranged on the shaft 3 of the electric motor 1 and is connected in a rotationally fixed manner to the inner rotor 4. In addition, the shaft 3 has a radial bearing with a bush 12 in that housing part 8 of the fuel pump 2 which faces away from the electric motor 1. A pump cover 13 has an intake pipe 14. On its end facing away from the fuel pump 2, the feed unit has a connecting pipe 15 for a fuel line which leads to the internal combustion engine. As a result, the supplied fuel f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com