Miniature rotary compressor, and methods related thereto

a compressor and miniature technology, applied in the field of miniature rotary compressors, can solve the problems of insufficient cooling effect, non-mobile, bulky, etc., and achieve the effect of sufficient cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

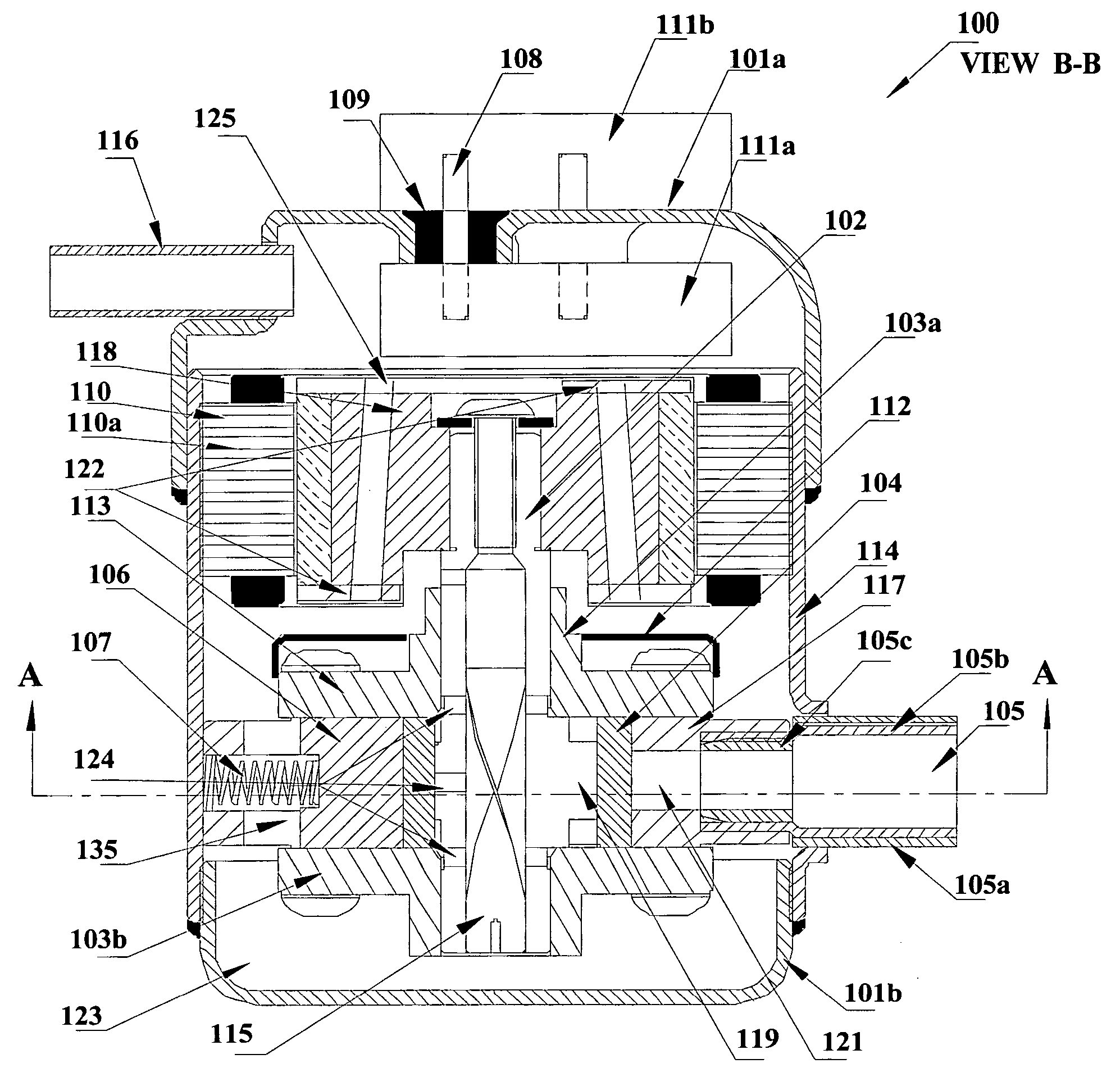

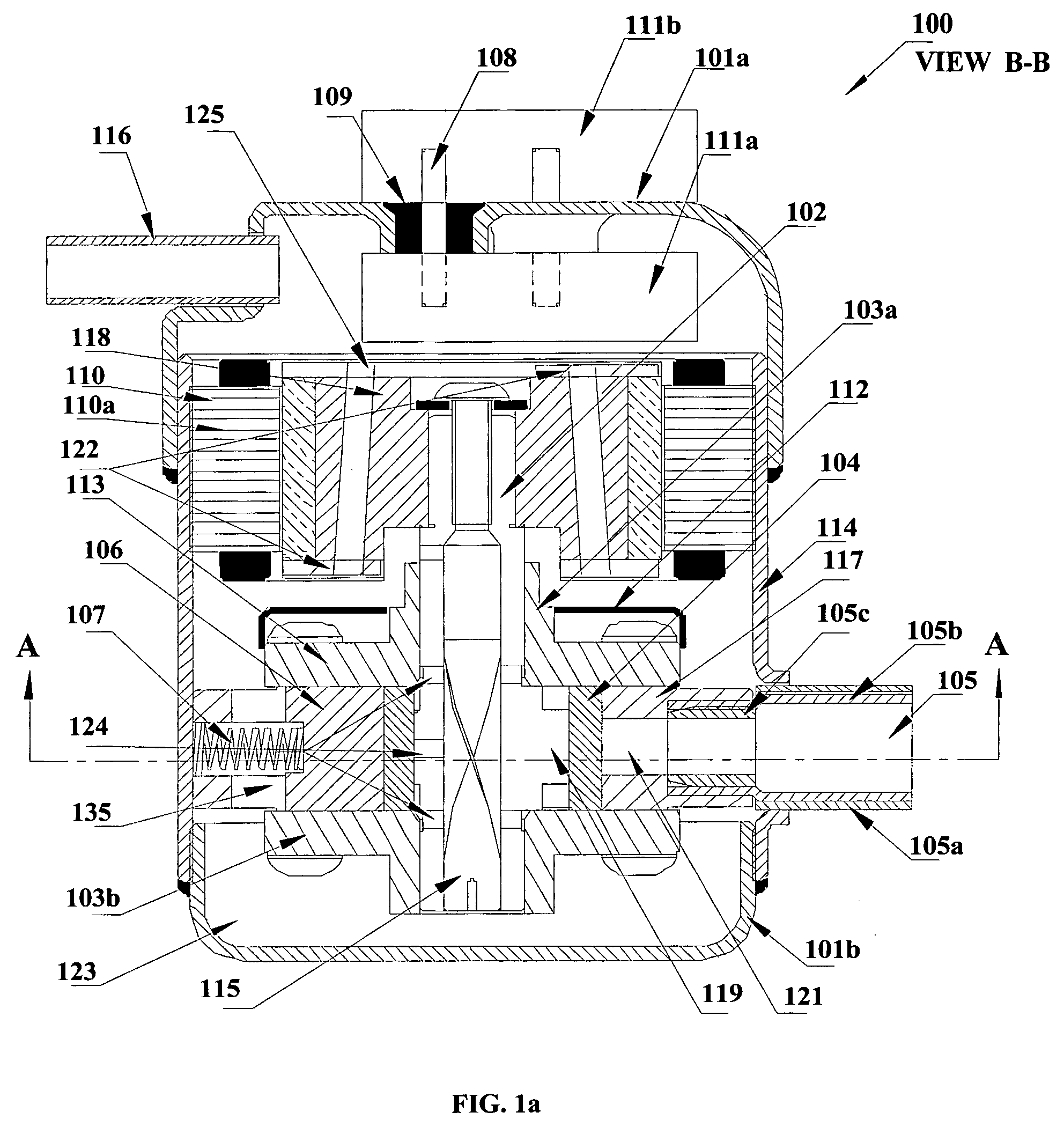

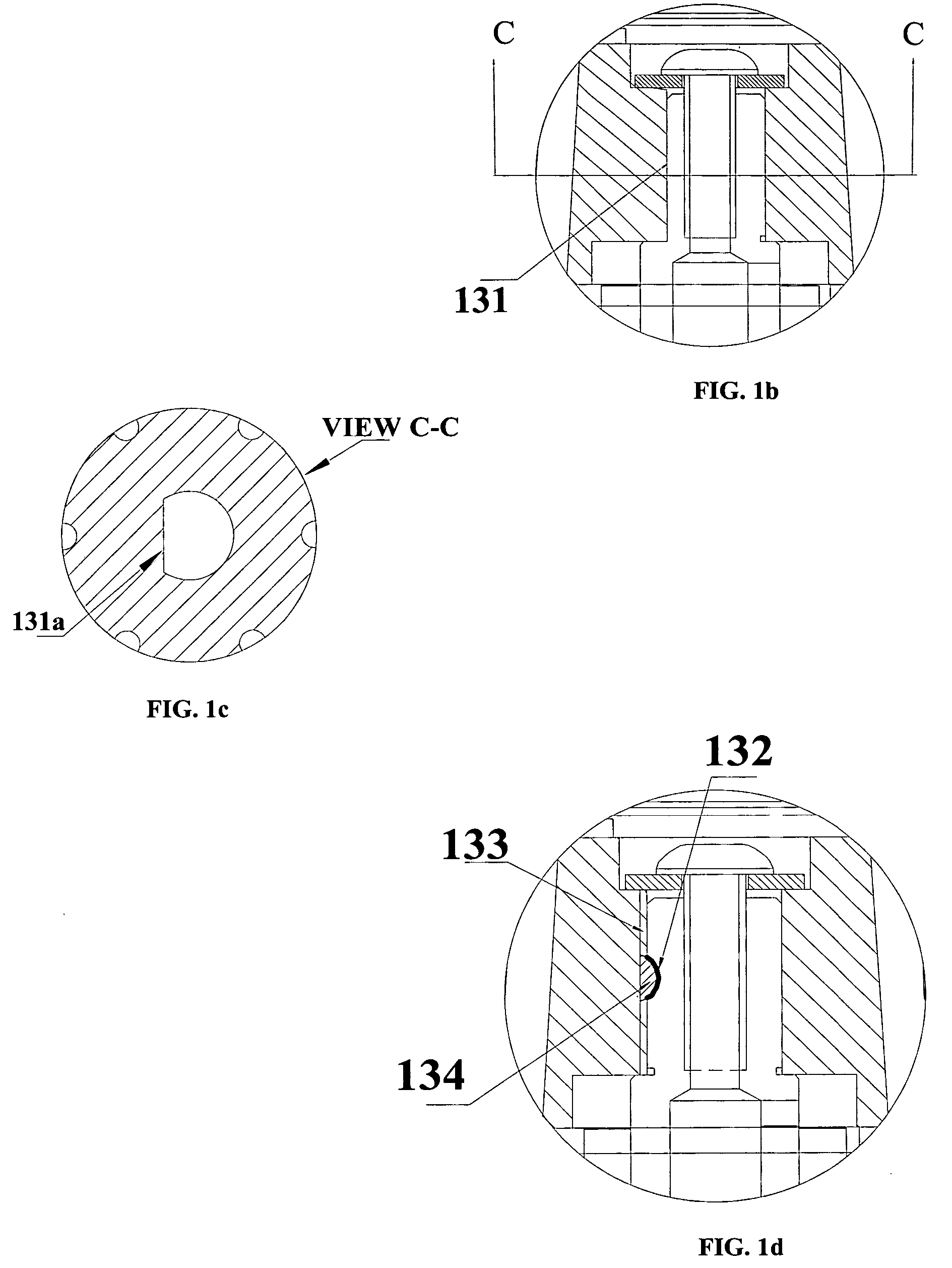

[0034] The present invention pertains to a miniature rolling piston rotary compressor for primary refrigerants designed primarily for portable refrigeration applications, such as in personal cooling systems, small refrigerators and freezers, portable blood coolers, beverage coolers, etc. where size, weight, and factors, such as efficiency, do not inhibit functionality. This miniature rolling piston rotary compressor is also suitable for small stationary applications, such as cooling for microprocessors, lasers, x-rays, and other electronic components that generate substantial amounts of heat.

1. Definitions

[0035] The term “ultralight” or “ultralight weight”, as used herein, refers to a mass that is low enough that when included within a complete refrigeration system with portable power supply, it can be mounted upon a person comfortably without encumbrance. Within this context, a compressor weight of less than 2.0 pounds and a cooling capacity of about 100 to about 500 Watts, can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com