Lever oil pump capable of eliminating eccentric wear and directly flushing well

An oil pump and positive washing technology, applied in the field of high-efficiency and energy-saving rod oil pump, can solve the problems of not eliminating eccentric wear, not having, not having positive flushing, etc., and achieve the effect of eliminating eccentric wear and eliminating bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

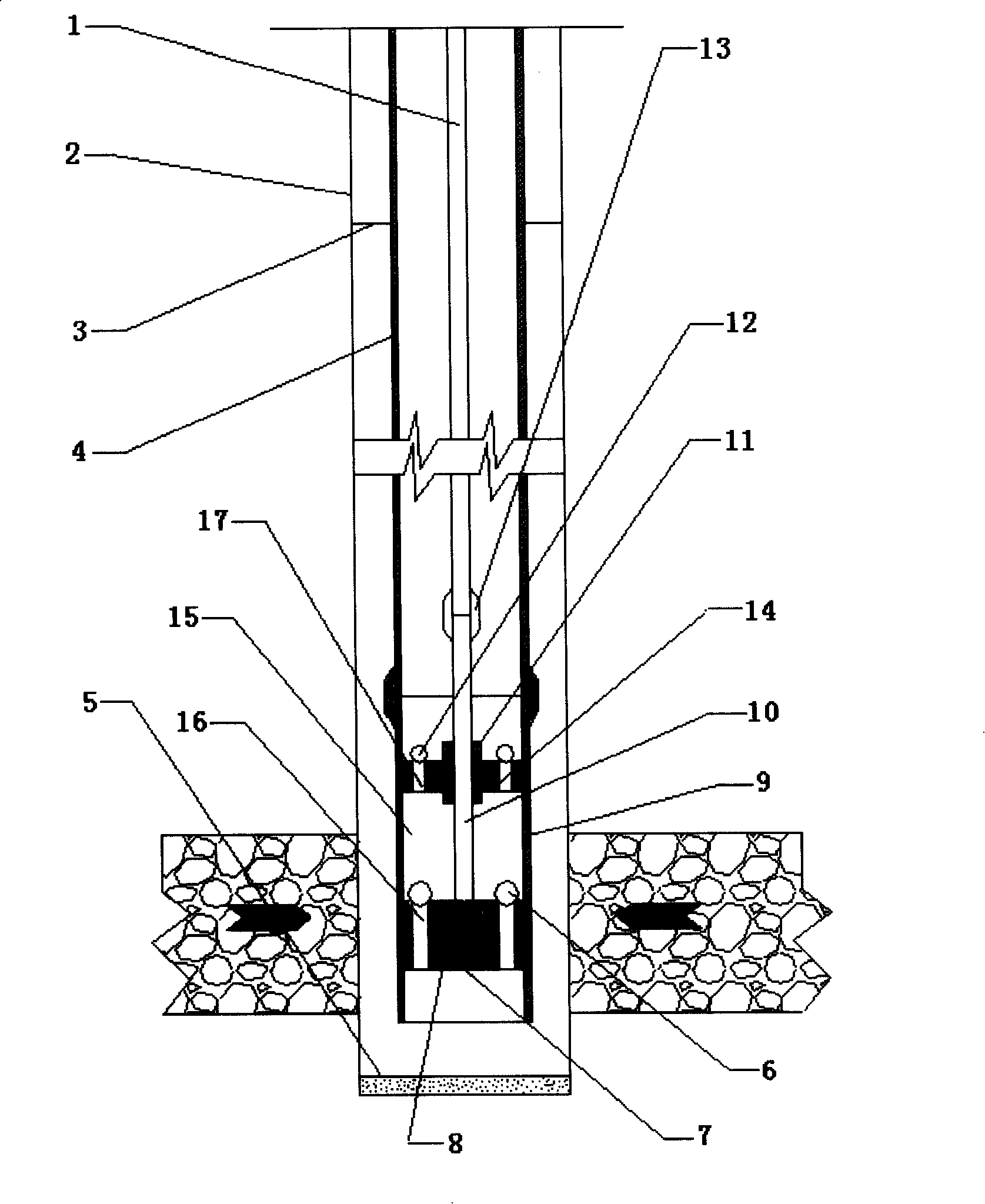

[0019] figure 2 It is a schematic diagram of the first embodiment of a rod well pump that can eliminate eccentric wear and can flush wells in the present invention. The rod well pump that can eliminate eccentric wear and can clean the well includes a sucker rod 21, a casing 22, a fluid surface 23, a tubing 24, a disconnecting mechanism 25, a pull rod 26, a long plunger 27, and a short pump barrel 28 , fixed valve 29, fixed valve base expansion pipe 30, long pump barrel 31, formation 32, pump cavity 33, pump barrel lower diameter expansion pipe 34, short plunger support 35 with flow passage, artificial well bottom 36, short Plunger lower end surface 37, short plunger 38, floating valve 39, fixed valve channel 40, fixed valve seat 41. The upper part of the long pump barrel 31 is connected with the expansion tube 30 of the fixed valve base, and the lower part is connected with the expansion tube 34 of the lower part of the pump barrel; the fixed valve seat 41 is located at the ...

no. 2 approach

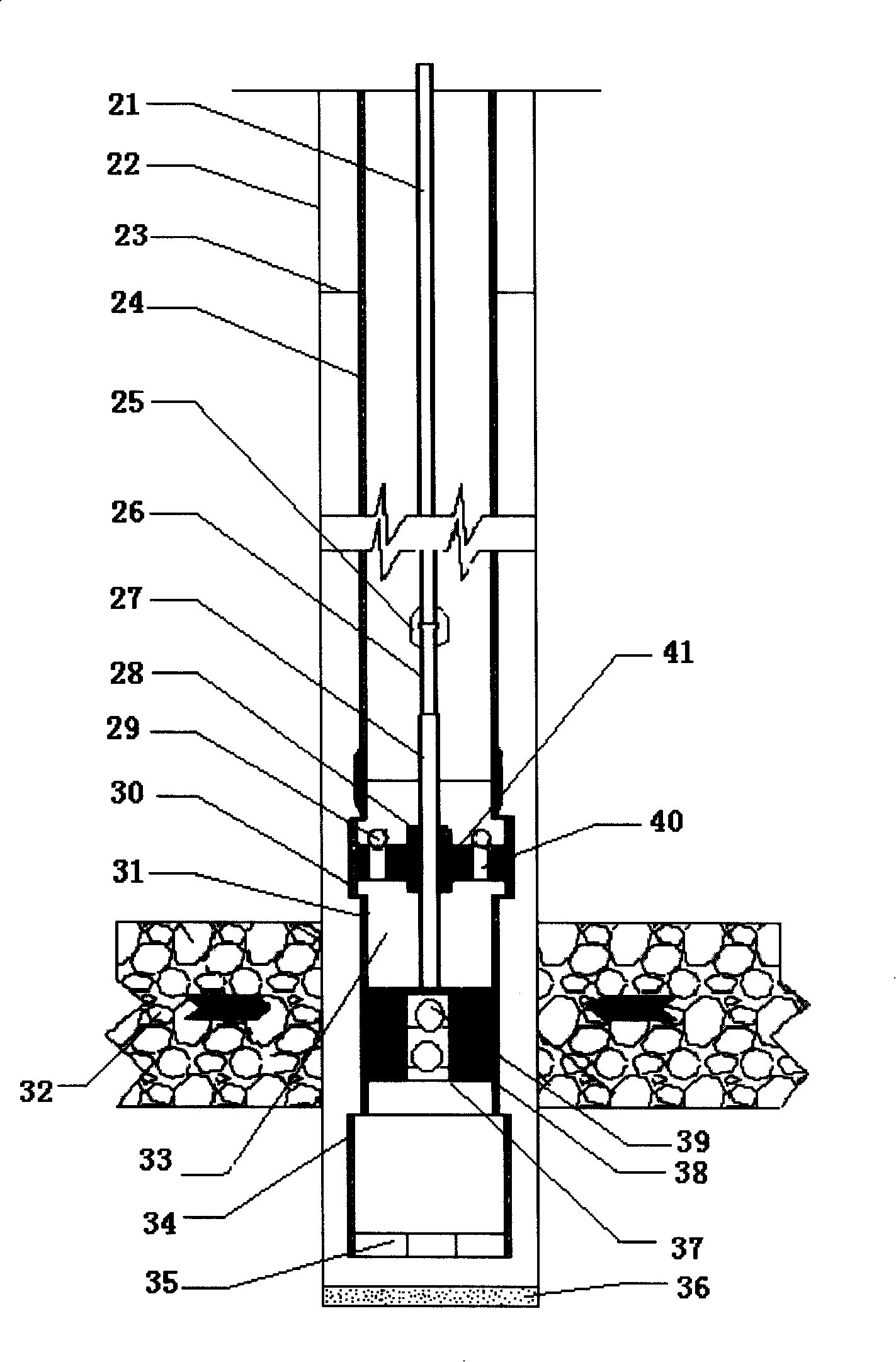

[0035] Figure 4 It is a schematic diagram of the normal oil pumping situation according to the second embodiment of the present invention, Figure 5 It is a schematic diagram of positive injection in the second embodiment of the present invention. From Figure 4 , 5 It can be seen that the second embodiment only changes the pull rod 26. Compared with the first embodiment, the pull rod 26 of the second embodiment no longer requires the diameter of the pull rod to be reduced, but the pull rod 26 is provided with a Groove 261, its slotting length will be greater than the length of short pump barrel 28, so that there is a fluid flow channel between the pull rod 26 and the short pump barrel 28, providing a fluid flow channel for positive well washing, positive injection and oil drainage.

[0036] The following analyzes how this embodiment eliminates the eccentric wear phenomenon. To eliminate the eccentric wear phenomenon in this embodiment, it is enough to ensure that the dia...

no. 3 approach

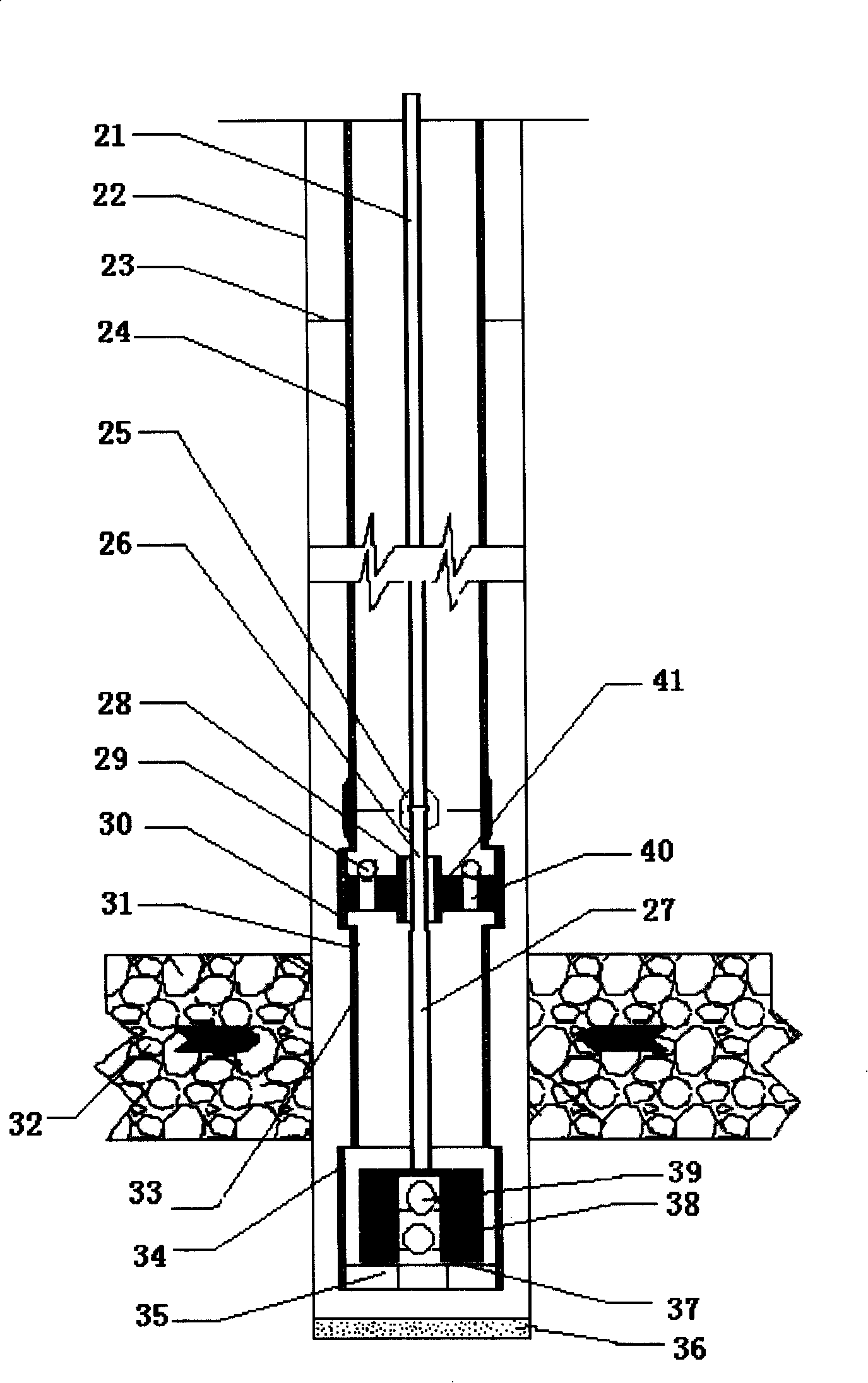

[0038] Figure 6 It is a schematic diagram of the normal oil pumping situation according to the third embodiment of the present invention, Figure 7 It is a schematic diagram of positive injection in the third embodiment of the present invention. From Figure 6 , 7 It can be seen that the third embodiment also changes the pull rod. Compared with the first embodiment, the pull rod 26 of the third embodiment no longer requires the diameter of the pull rod to be reduced, but opens the center on the pull rod. Hole 263 and open vertical hole 262,264 at the top and bottom of pull rod, vertical hole 262,264 communicates with center hole 263, the distance of upper and lower vertical hole 262,264 is greater than the length of short pump cylinder 28, makes the hole on the pull rod 262, 263, 264 become fluid flow channels, thereby providing fluid flow channels for positive well washing, positive injection and oil drainage.

[0039] The following analyzes how this embodiment eliminate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com