Inlet and outlet damping expansion joint of anti-fatigue type pump

An anti-fatigue, expansion joint technology, used in pipeline expansion compensation devices, pipes/pipe joints/pipes, damage protection, etc. The radial and axial deformation of the bellows, the short service life of the expansion joint, etc., can improve the service life, reduce the radial deformation, and reduce the radial stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

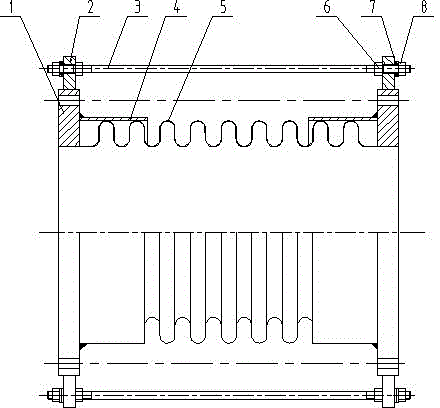

[0017] The anti-fatigue pump inlet and outlet shock-absorbing expansion joints shown in the accompanying drawings include flange 1, limit sheath 4 and bellows 5; flange 1 is welded to both ends of bellows 5; There is an ear plate 2, the pull rod 3 passes through the ear plate 2, and the two ends are connected together by nuts 8; the inner end of the ear plate 2 is provided with an adjusting nut 6; A spherical gasket and a conical gasket assembly 7 are provided between them.

[0018] The inner wall of the bellows 5 is provided with a corrosion-resistant layer. In this embodiment, the corrosion-resistant layer is a Teflon coating.

[0019] The limit sheath 4 is set on the bellows 5, and its inner wall is in contact with the crest of the bellows 5. In this embodiment, the limit sheath 4 contains two sections of bellows, and there are two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com