Three-blade concave face ball-tooth dill bit applicable to self-drilling type hollow anchoring system

An anchoring system and self-drilling technology, which is applied in construction and other fields, can solve the problems of lower drilling efficiency, side teeth slipping, lack of drill bits, etc., and achieve the effect of improving cleaning effect, wide cutting range and good cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

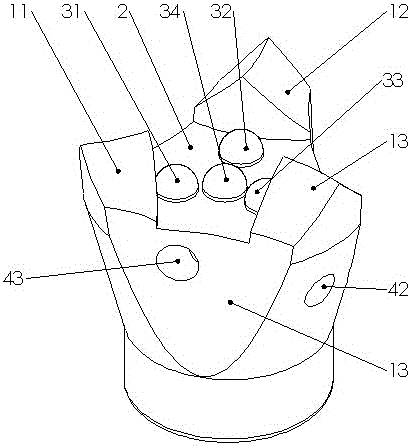

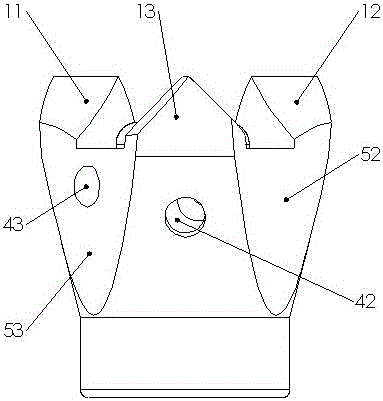

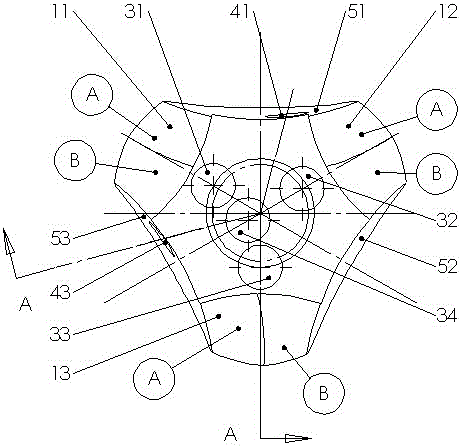

[0037] like Figure 1-4 As shown, the three-edged concave button drill bit suitable for the self-drilling hollow anchor system of the present invention includes two parts, the head and the trouser body. The head is provided with three cutting edges, a lower groove 2 and 4 button teeth distributed in the lower groove 2 . There are three arc-shaped chip removal grooves evenly distributed on the outer wall of the trousers, which are used for chip removal during drilling; the first water outlet hole 41 and the second water outlet hole 43 are distributed in the chip removal groove, and the outer wall of the trousers is provided with 1 water hole 42, used for passing pressure water, flushing cuttings and cooling drill bit cutting edge. There is a threaded cavity inside the trouser body, which can be screwed with the external thread of the self-drilling rod body, and realizes the energy transmission required for drilling, and communicates with the water hole 42 through the internal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com