A kind of anchor for carbon fiber parallel cable and its anchoring method

An anchoring method, carbon fiber technology, applied in construction, building reinforcements, bridge construction, etc., can solve the problems of rod body damage anchorage efficiency, uneven stress distribution in the anchorage area, etc., to increase anchorage efficiency, improve anchorage efficiency, and reduce stress concentrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

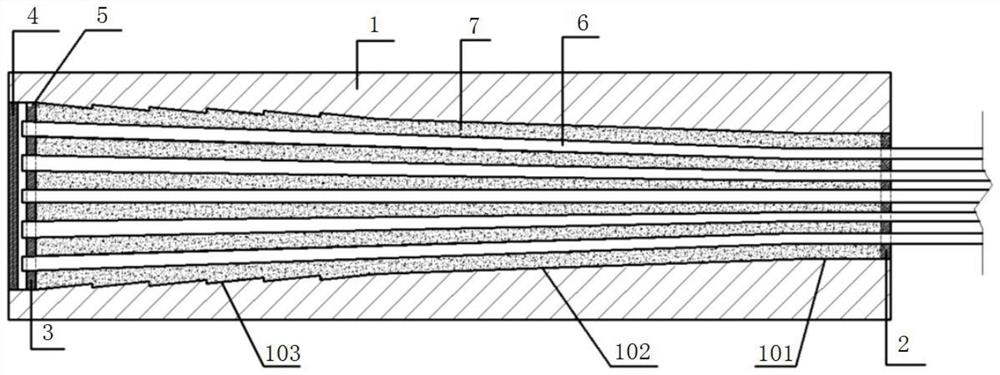

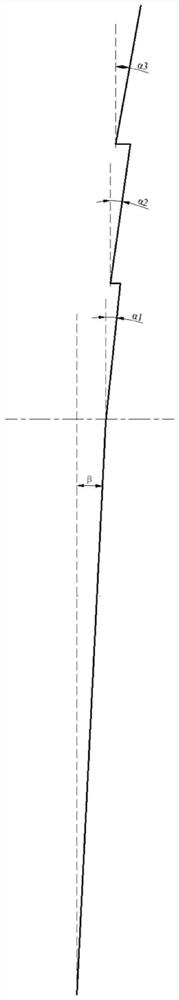

[0028] Embodiment 1. An anchor for carbon fiber parallel cables in this embodiment includes an anchor cup 1, a front-end wire dividing plate 2, a rear-end wire dividing plate 3, and a sealing bolt 4. The sealing bolt 4 is connected to the anchor cup 1. The inner diameter of the rear end is threaded, and the anchor cup 1 is an integral structure composed of a front straight section 101, a middle straight cone section 102 and a rear triangular groove section 103. The inner cavity of the front straight section 101 is cylindrical. The inner cavity of the middle straight cone section 102 is in the shape of a truncated cone, the inner cavity of the rear end triangular groove section 103 is in the shape of a tower-shaped truncated cone, and one end of the rear end wire dividing plate 3 is connected with the inner cavity of the anchor cup 1 The exhaust hole 5 of the rear end triangular groove section 103, the angle between the truncated truncated busbar and the axis of each layer of th...

Embodiment 2

[0029] Embodiment 2. The method of anchoring the carbon fiber parallel cable with the anchor of embodiment 1 is carried out according to the following steps:

[0030] Step 1: Fix the anchor cup 1 on the workbench, insert the carbon fiber rod 6 into the holes on the front end splitter plate 2 and the rear end splitter plate 3 in turn, and then clamp the rear end splitter plate 3 on the anchor cup. The rear end of 1, forming a carbon fiber cable;

[0031] Step 2: Lift the anchor cup 1, perpendicular to the ground, and pour the epoxy iron sand 7 from the front end of the anchor cup 1. The epoxy iron sand 7 is a mixture of epoxy resin and iron sand. It is located at the front end port of the anchor cup 1, and the air is discharged from the exhaust hole 5 on the rear end splitter plate 3 through constant vibration, so that the epoxy iron sand 7 is filled in the anchor cup 1 densely, and then the sealing bolt 4 is screwed on. After heating and curing, the anchoring is completed, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com