High-temperature composite machine with high temperature compensation function

A technology of temperature compensation and compound machine, which is applied in the field of compound machine, can solve the problems of precision error and uneven material thickness, and achieve the effects of reducing influence, ensuring precision requirements and avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

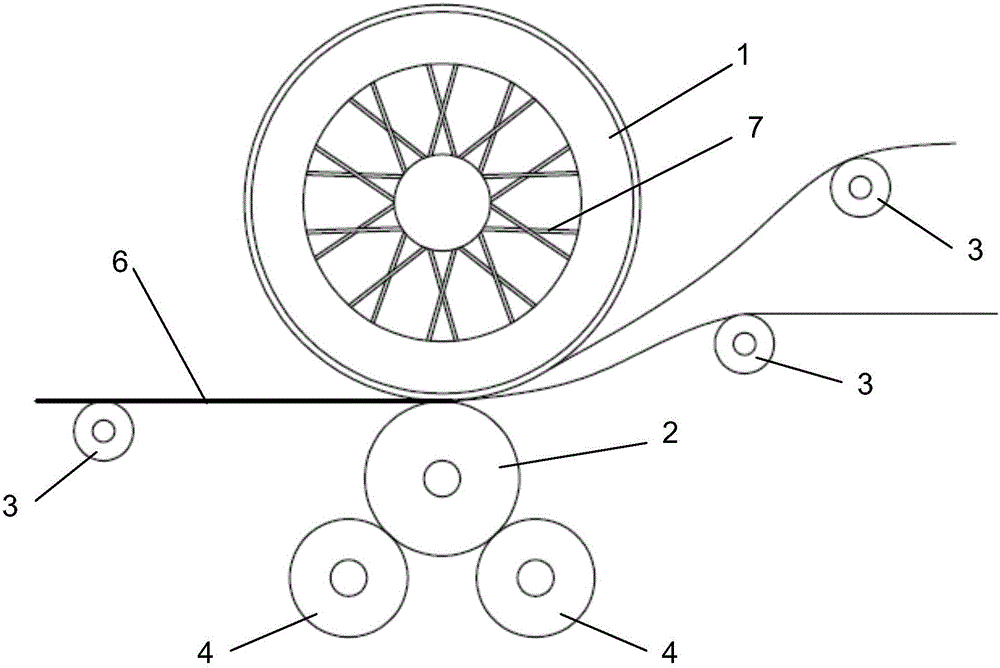

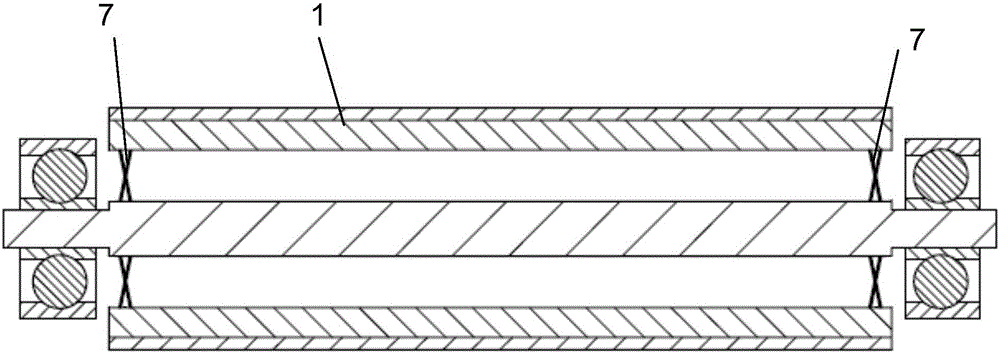

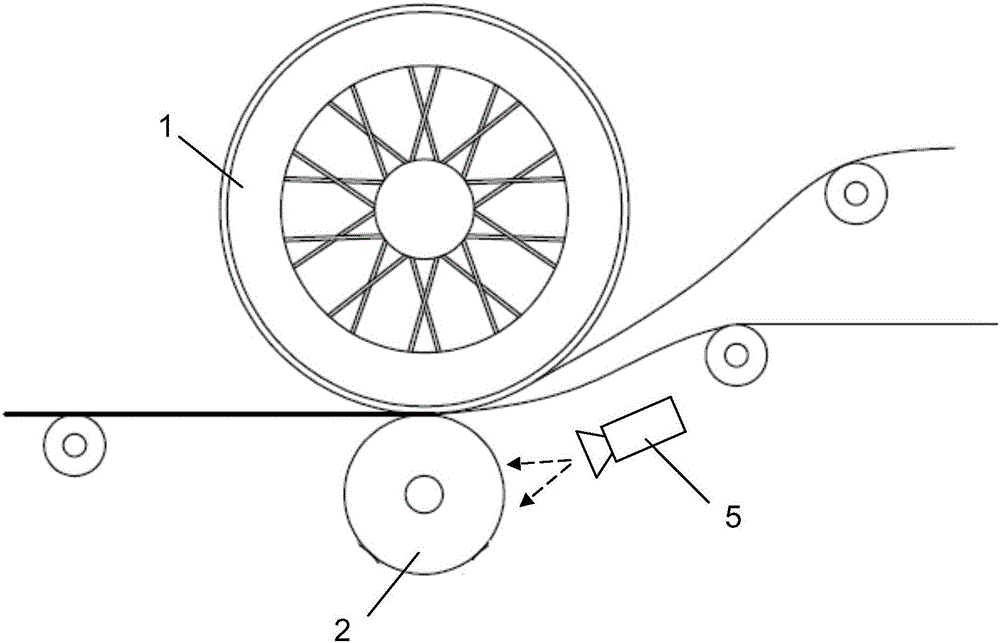

[0016] see Figure 1 ~ Figure 3 As shown, a kind of high-temperature composite machine with temperature compensation function of the present invention is the same as the prior art, and also includes a heating composite roller 1 (metal material) and a rubber roller 2 that are arranged up and down, and is used for composite materials. 6. Conveyor roller 3 for conveying. Different from the prior art, this composite machine also includes a cooling mechanism for cooling (temperature compensation) the rubber roller 2. Through this cooling mechanism, the rubber roller 2 is cooled to below 200°C. Through such temperature compensation, the thermal deformation of the rubber roller surface can be avoided, thereby reducing the influence on the thickness of the composite material, and ensuring that the thickness of the product is accurate and consistent wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com