Intelligent fixture clamping protecting device

A protection device and fixture technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of bending, damage, and affecting product quality at the edge of the steel coil, and achieve the elimination of bending at the edge of the steel coil, which is suitable for popularization and application , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

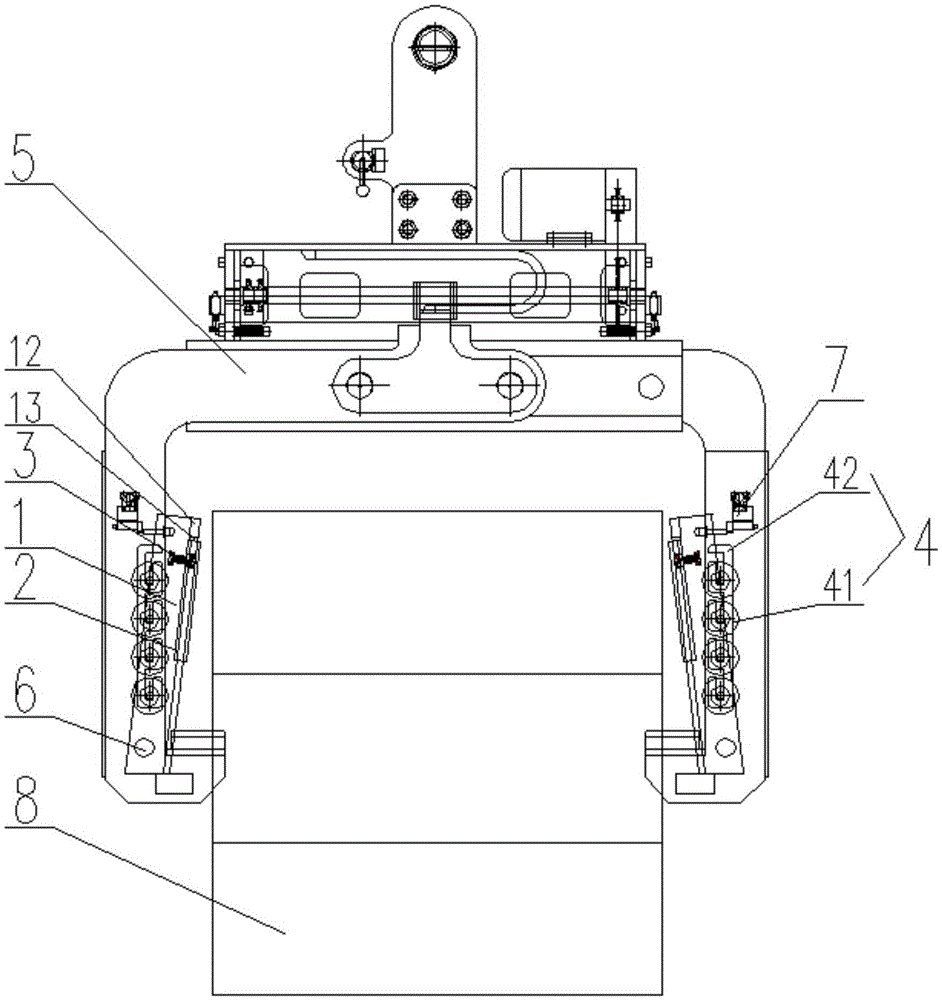

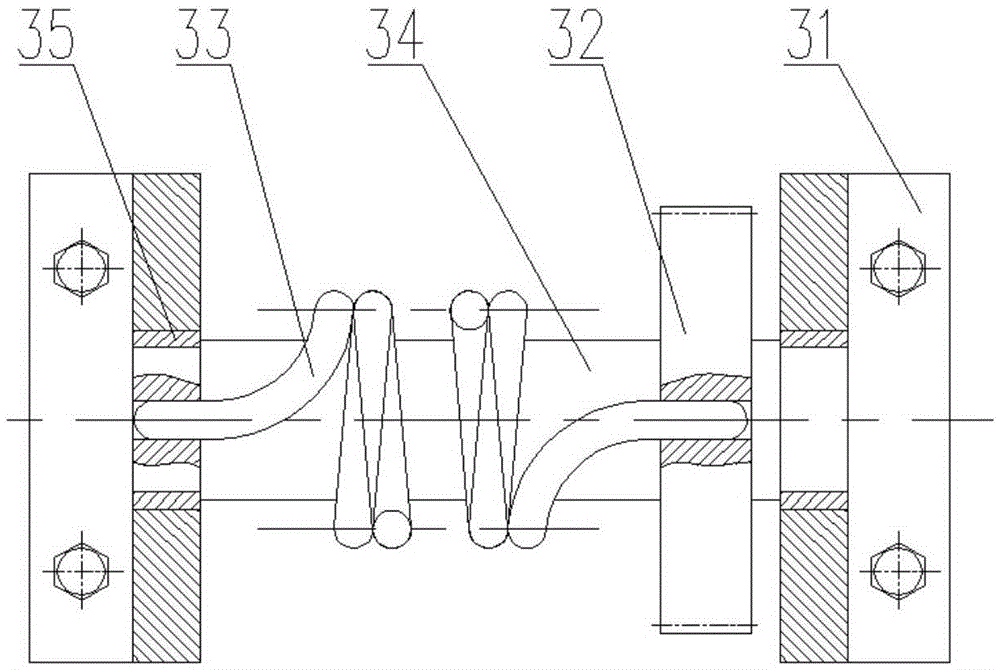

[0021] As shown in the figure, the intelligent fixture clamping protection device in this embodiment includes a swing frame 1, a sliding plate 2, a driving device 3 and a rolling device 4. The swing frame 1 is hinged on the fixture body 5, and the sliding plate 2 is fitted on the swing frame 1 and can move up and down along the swing frame 1. The driving device 3 is arranged on the swing frame 1 and cooperates with the sliding plate 2. The rolling device 4 is matched with the sliding plate 2 and is correspondingly arranged on the On the fixture body 5. This device enables the contact part between the fixture body 5 and the steel coil 8 to move up and down freely with the steel coil 8 through the sliding plate 2, and the sliding plate 2 automatically recovers through the action of the driving device 3, so as to ensure that the sliding plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com