Integral forging near net shaping process for triple gear block, and prepared gear shaft

A near-net forming and integral forging technology, applied to components with teeth, belts/chains/gears, mechanical equipment, etc., can solve problems such as inability to assemble, high requirements for machining equipment, and large material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Further detailed description will be given below in conjunction with the accompanying drawings.

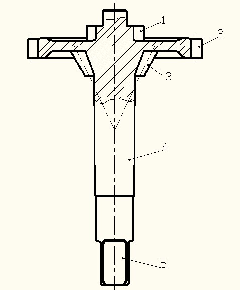

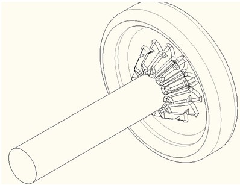

[0026] As shown in the figure, wherein: 1 is a small spur gear, 2 is a large spur gear, 3 is a bevel gear, 4 is a handle, 5 is a handle end, and 6 is a positioning sleeve.

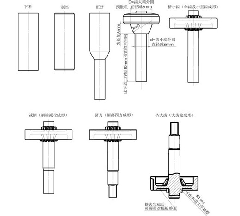

[0027] Firstly, the cold forging process is simulated according to the three-dimensional modeling software, and the mold making and material preparation are designed. The raw material of the bevel gear shaft in this embodiment is 20CrMnTi round steel bar. see Figure 1 to Figure 5 Its process steps are:

[0028] 1. Take the 20CrMnTi round steel bar and saw and cut it. After blanking, the weight of the raw material billet is greater than 8% of the weight of the finished forging billet.

[0029] 2. Machining to make billets, machining to remove the oxide skin on the surface of the raw billet, and ensuring that the weight of the billet is 3% greater than the weight of the finished forging billet.

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com