Novel low smoke zero halogen fire resistant armoured cable

A low-smoke flame-retardant, armored cable technology, applied in the field of wire and cable, can solve the problems of poor tear resistance, shortened service life, low elongation at break, etc., to achieve wide application prospects, good social benefits and economic effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

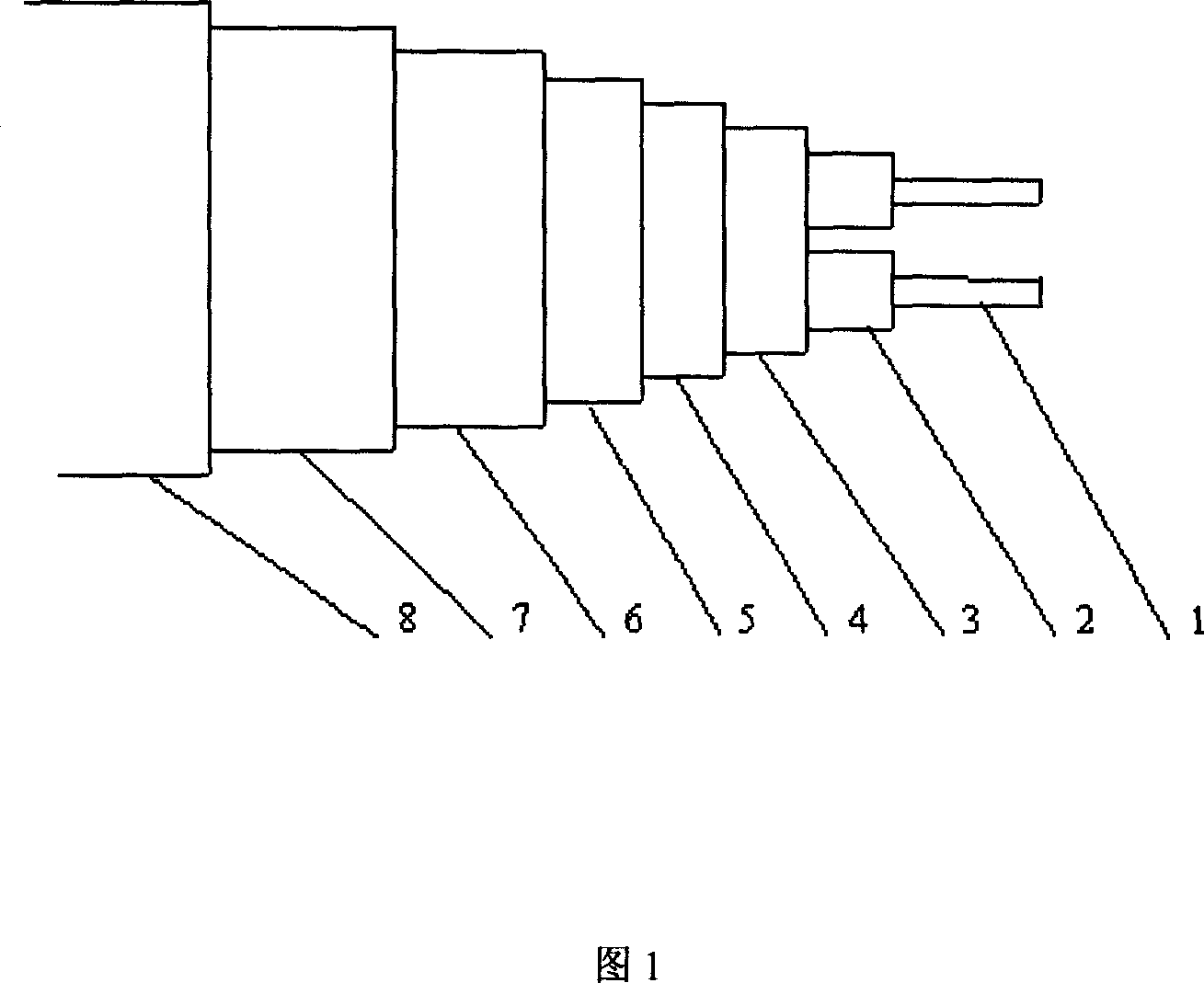

[0027] Halogen-free low-smoke flame-retardant XLPE insulated polyolefin sheathed steel tape armored power cable, WDZ-JYY 23 3×50 0.6 / 1kV:

[0028] 50mm 2 Copper conductor 1, cross-linked polyethylene insulation 2, three-core insulated core 9 twisted cable 11, wrapped with a layer of non-woven fabric 3, polyolefin inner sheath 5, double-layer interval wrapped steel tape armor 6, wrapped Two layers of halogen-free low-smoke glass ribbon 7, extruded halogen-free low-smoke flame-retardant polyolefin outer sheath 8.

Embodiment 2

[0030] Halogen-free low-smoke flame-retardant steel tape armored computer cable, WDZ-DJYYP 2-23 20×2×0.5450 / 750V:

[0031] 0.5mm 2 Copper conductor 1, polyethylene insulation 2, 2 insulated wire cores 9 twisted into a wire group 10, 20 wire groups 10 twisted cables 11, polyester wrapping tape 3, copper tape wrapping shielding 4, polyolefin inner sheath 5 , double-layer spaced steel tape armor 6, wrapped with two layers of low-smoke halogen-free glass ribbon 7 and a layer of non-woven fabric 7, extruded low-smoke halogen-free flame-retardant polyolefin outer sheath 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com