A partition spray bottle washing device

A technology for rinsing bottles and bottle washing machines, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc. It can solve the problems of increasing equipment investment and operating costs, huge bottle washing settings, and low bottle washing efficiency. Achieve the effects of ensuring the flushing effect and flushing quality, saving water resources, and high bottle washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

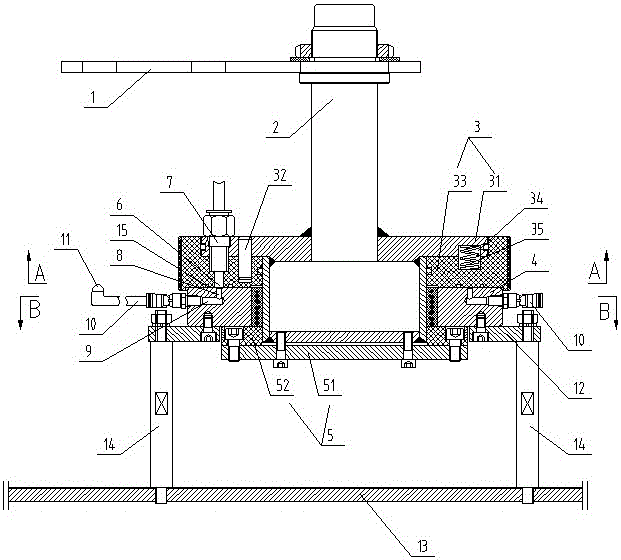

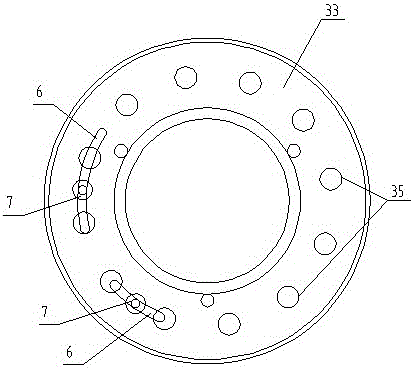

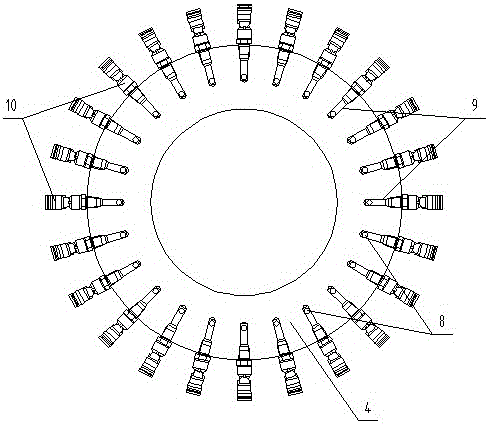

[0015] Such as figure 1 The shown partition spray bottle washing device includes a support frame 1 fixed on the body of the bottle washing machine, a support shaft 2 is installed on the support frame 1, and an upper pressing plate 3, The distribution plate 4 and the lower ring plate 5, the lower surface of the upper pressing plate 3 and the upper surface of the distribution plate 4 rotate and seal, the distribution plate 4 is driven by the power device connected to the body of the bottle washing machine, and the lower part of the support shaft 2 is also The lower ring plate 5 is installed to press the distribution plate 4 and the upper pressure plate 3. The upper pressure plate 3 includes the upper pressure plate 31 fixed on the support shaft 2 and the upper pressure plate 31 connected to the upper pressure plate 31 through the insertion column 32. The upper water distribution plate 33, the joint surface of the upper pressure plate 31 and the upper water distribution plate 33 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com