New method for washing chlorine of nickelous hydroxide

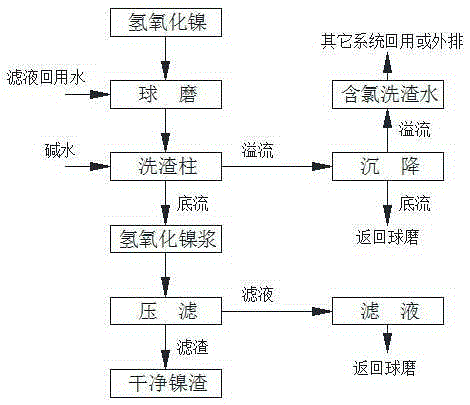

A technology of nickel hydroxide and a new method is applied in the field of slag washing section in the chemical and metallurgical fields, which can solve the problems of large investment, high operating cost, long process, etc., and achieve the effect of simplifying the slag washing process and reducing labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

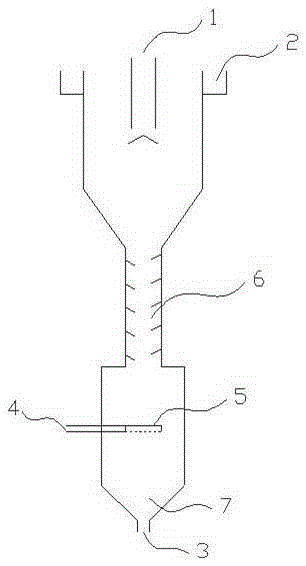

[0019] A nickel hydroxide sample contains 45% nickel and 0.5% chlorine on a dry basis, with a nickel-to-chlorine ratio of 90. After it is ball-milled to -300 mesh by a ball mill, it enters the material inlet (1) at the top of the slag washing column for slag washing. Simultaneously, the alkaline water with the pH of 13.5 prepared with new water and sodium hydroxide enters the washing water inlet (4) below the slag washing column.

[0020] After being washed by the slag washing column, the clean nickel hydroxide slurry is discharged from the material outlet (3) at the bottom of the slag washing column, and the slag washing water overflows from the washed water outlet (2) above the slag washing column. After the slag washing water overflowed from the washing water outlet (2) of the slag washing column passes through the sedimentation, the overfl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com