System for producing 2,3,5,6-4-methoxymethyl-tetrafluorobenzyl alcohol

A technology of methoxymethyl and tetrafluorobenzyl alcohol, which is applied in the field of continuous production, can solve the problems of high by-products and low purity of crude benzyl alcohol, and achieve the effects of high production safety, short reaction time and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

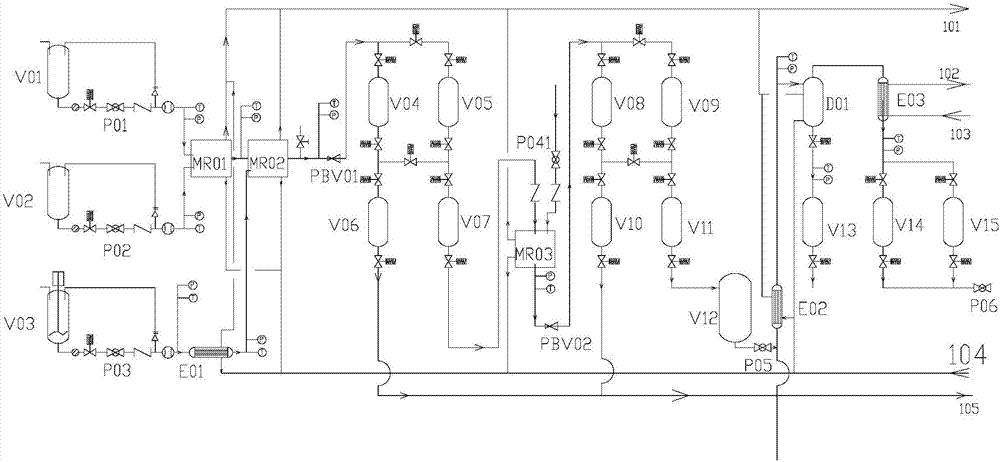

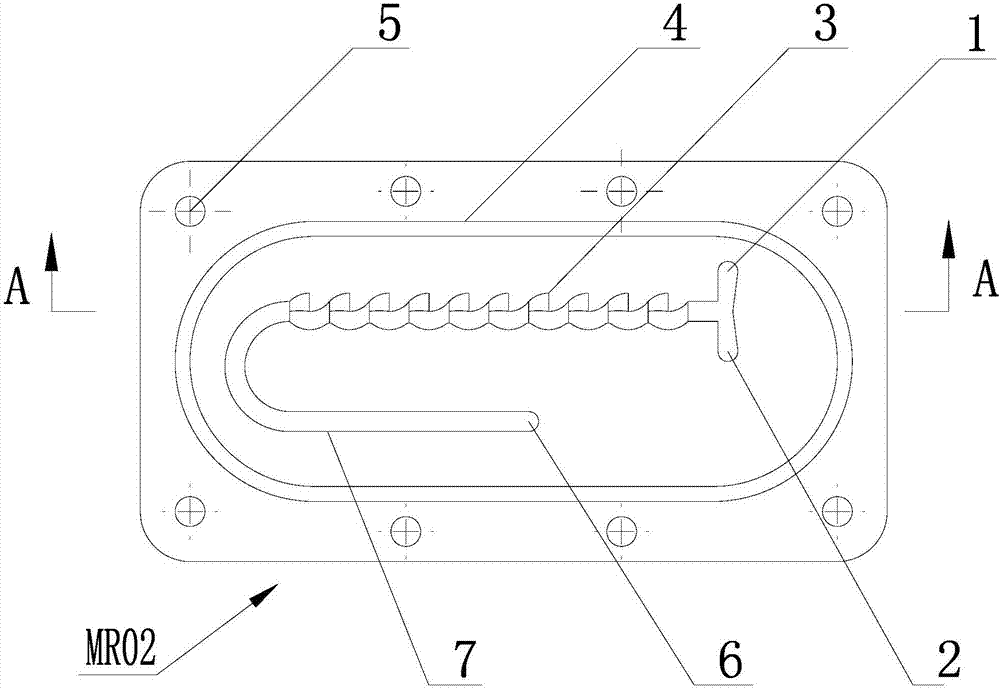

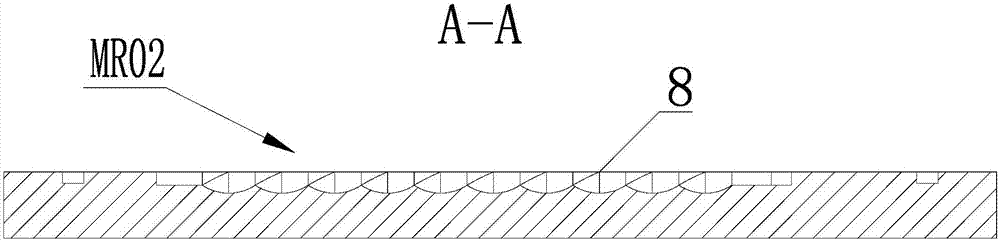

[0039] Such as figure 1 As shown, prepare the aqueous solution of dialcohol alkali, and the molar ratio is diol: caustic soda: reaction water=1:1.5:8 ingredients, prepared and placed in its aqueous solution storage tank V03 for subsequent use; toluene, dimethyl sulfate Add toluene raw material storage tank V01 and dimethyl sulfate raw material storage tank V02 respectively, the molar ratio of materials is diol: dimethyl sulfate: toluene=1:1.5:3; toluene pump P01 and dimethyl sulfate pump P02 is fed at a flow rate of 1.31 liters / minute and 0.86 liters / minute respectively, and the heat exchange setting is 60 degrees. After entering the mixer MR01, the dialcohol alkali aqueous solution after heat exchange with the first heat exchanger E01 is in the microchannel reactor MR02 Inlet confluence, in which the flow rate of dialcohol-alkali water pump P03 is controlled to 1.78 liters per minute, the heat exchange setting is 60 degrees, the back pressure of the back pressure valve I BPV0...

Embodiment 2

[0041] Such as figure 1 As shown, the preparation of diol alkali aqueous solution is diol: tablet alkali: reaction water=1:1.8:5 ingredients in molar ratio, prepared and placed in its dialcohol alkali aqueous storage tank V03 for subsequent use; toluene, dimethyl sulfate Add to toluene raw material storage tank V01 and dimethyl sulfate raw material storage tank V02 respectively, the molar ratio of materials is diol: dimethyl sulfate: toluene=1:1.2:5; toluene pump P01 and dimethyl sulfate pump P02 is fed at a flow rate of 4.38 liters / minute and 1.38 liters / minute respectively, and the heat exchange setting is 70 degrees. After entering the mixer MR01, the aqueous solution of dialcohol alkali after heat exchange with the first heat exchanger E01 is in the microchannel reactor MR02 Inlet confluence, in which the flow rate of dialcohol-alkaline water pump P03 is controlled to 3.54 liters per minute, the heat exchange setting is 70 degrees, and the back pressure of the first back p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com