Improved glazing inspection system

A technology for inspection systems and glass substrates, applied in the field of inspection systems, can solve problems such as imperfect cleaning and sensitivity to pollutants, and achieve improved inspection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

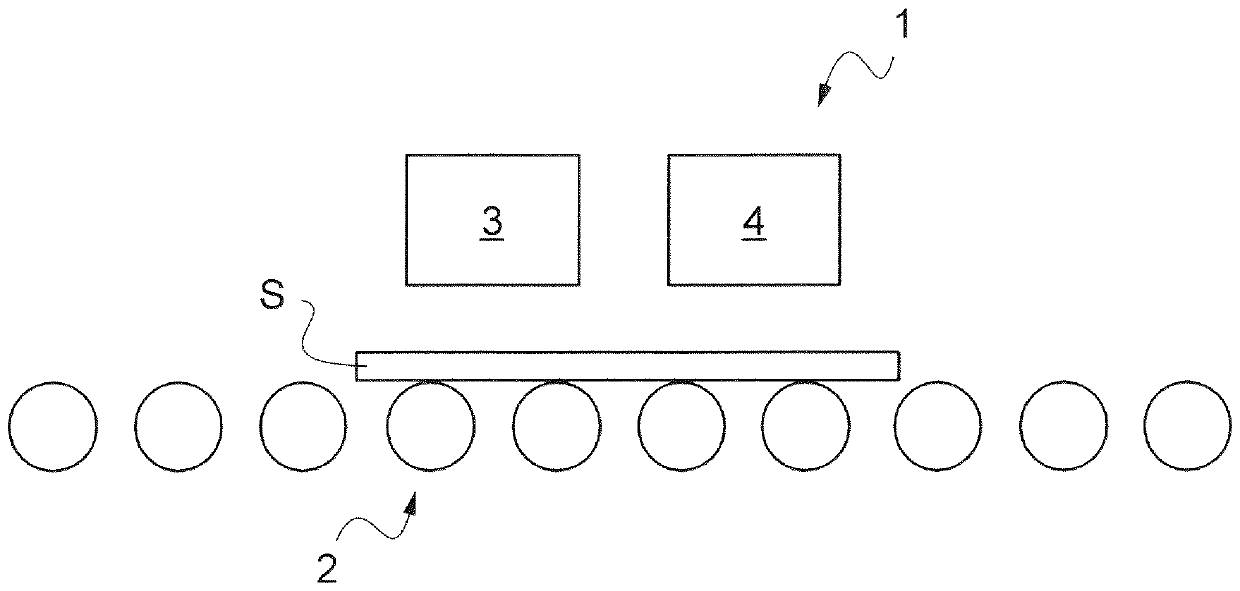

[0033] in figure 2 An inspection system 100 for inspecting a substrate S according to the present invention is shown in FIG. The substrate S is, for example, a wide glass substrate, such as a flat glass plate with a “mega” size (6 m×3.21 m) from the float glass process. Of course, the inspection system for inspecting the substrate S according to the present invention can be applied to substrates of different sizes. The substrate is inspected before processing.

[0034] The inspection system 100 includes a transport tool 102 for transporting the glass substrate S. Such a transfer tool 102 may take the form of two parallel rails on which a chassis is arranged, and the chassis is provided with supports for glass substrates. The transfer tool 102 may also take the form of two parallel rails on which are mounted wheels that enable the substrate to move. Then some wheels are connected to the motor to enable the base plate to be driven.

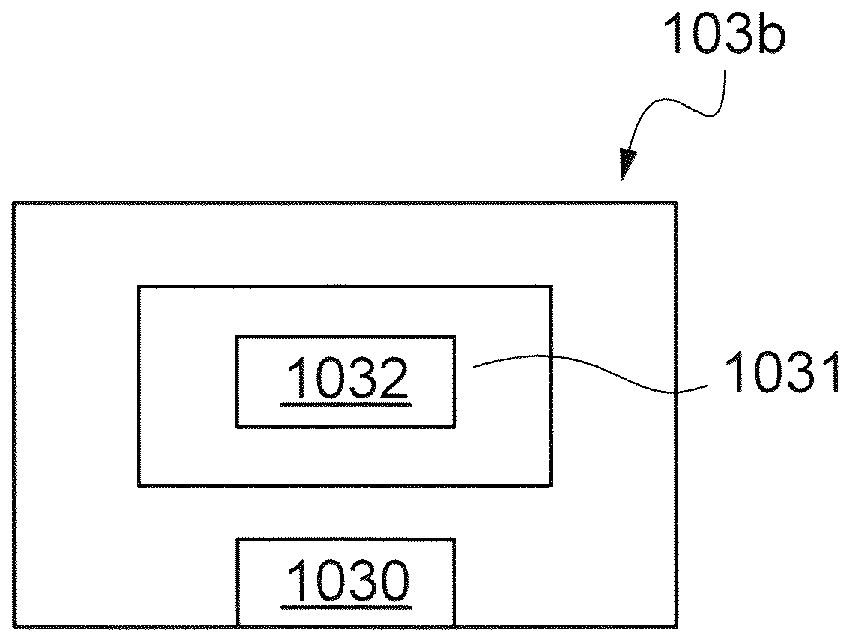

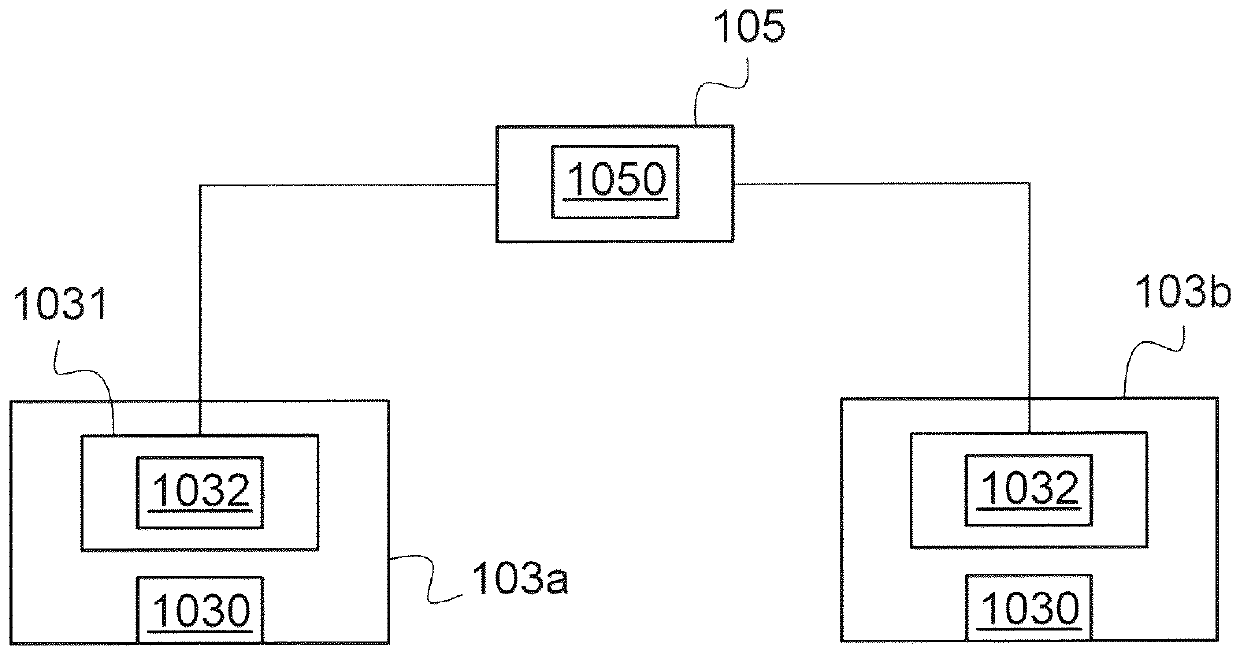

[0035] The inspection system 100 includes a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com