Method for recovering zinc from acid pickling waste liquid by using solvent extraction

A technology of pickling waste liquid and extraction, which is applied in the field of zinc recovery, can solve the problems of increased difficulty in zinc recovery and utilization, and achieve the effects of low operating cost, simple process, and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

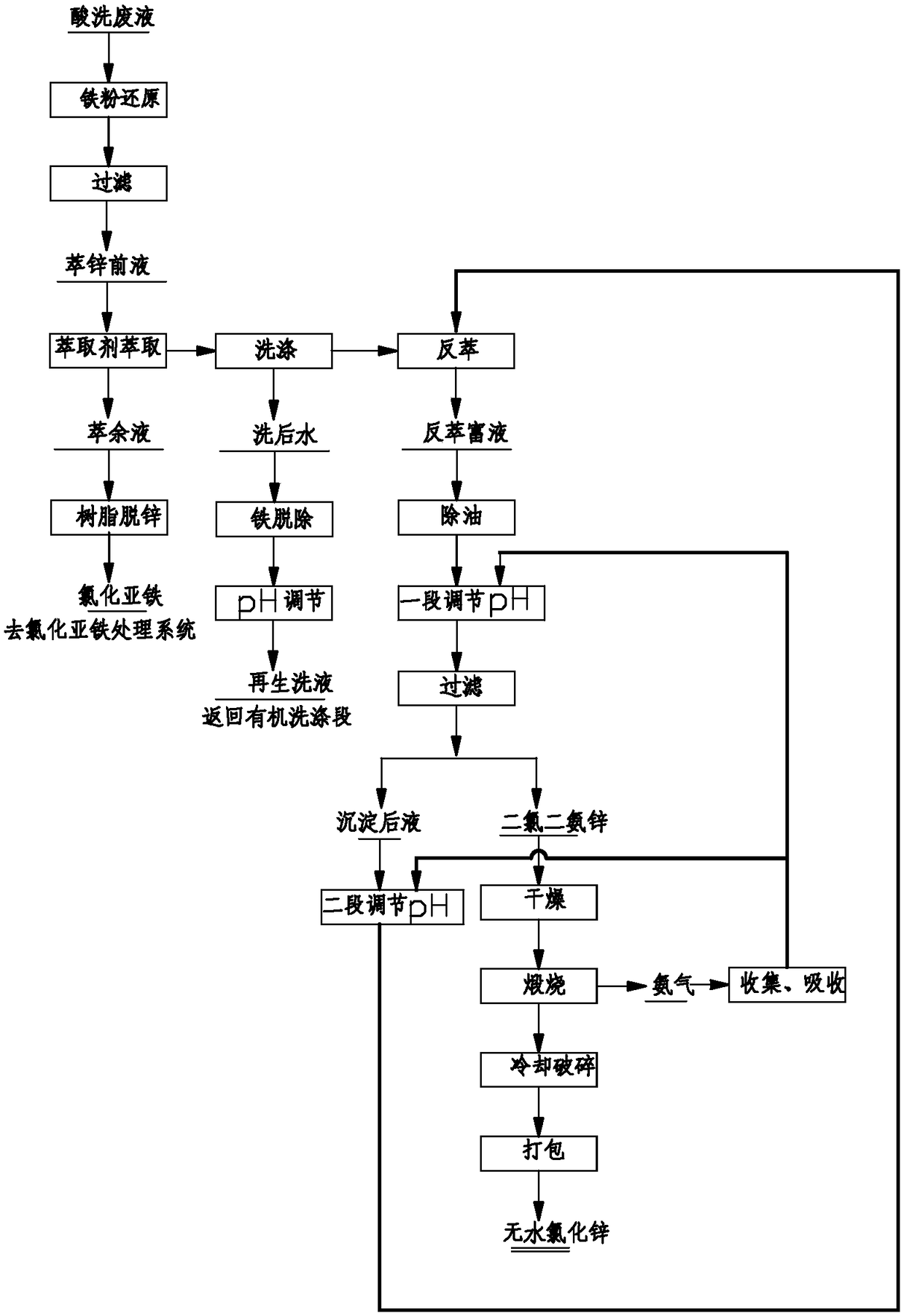

Image

Examples

Embodiment Construction

[0027] A kind of method adopting solvent extraction to reclaim zinc from pickling waste liquid, described step comprises:

[0028] a) Reduce the pickling waste liquid containing zinc and iron ions through iron powder, reduce the ferric iron in the pickling waste liquid to ferrous iron, and use hydrochloric acid to control the acidity of the pickling waste liquid, and the pickling waste liquid The pH is controlled at less than 1.0.

[0029] b) Filtrating the pickling waste liquid obtained in step a) to obtain the pre-zinc extraction liquid.

[0030] c) Mix and extract the pre-zinc extraction solution obtained in step b) with the extractant. The extractant is a neutral extractant. The extraction temperature is 20-50 degrees, the shaking time is 1-10 minutes, and the load is obtained by standing and stratifying. Organic as well as raffinate of zinc chloride. In this embodiment, the zinc content of the obtained raffinate is less than 0.5g / L, and the resin method can be used to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com