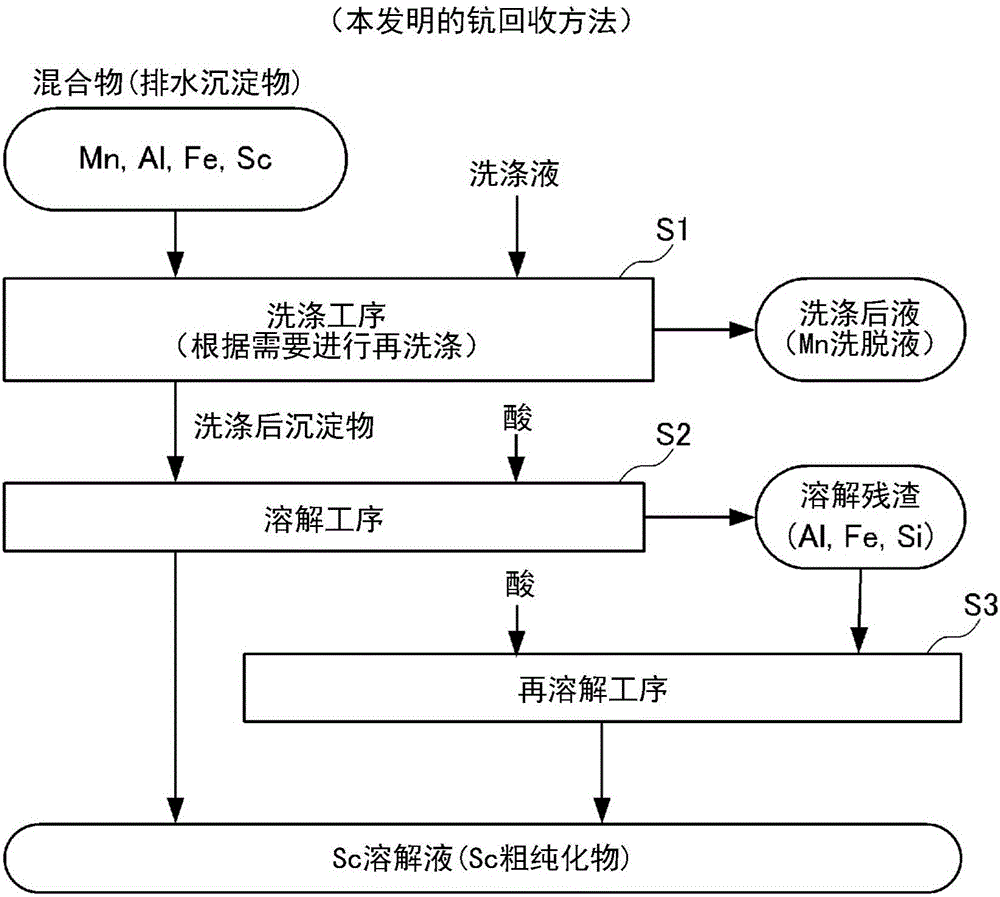

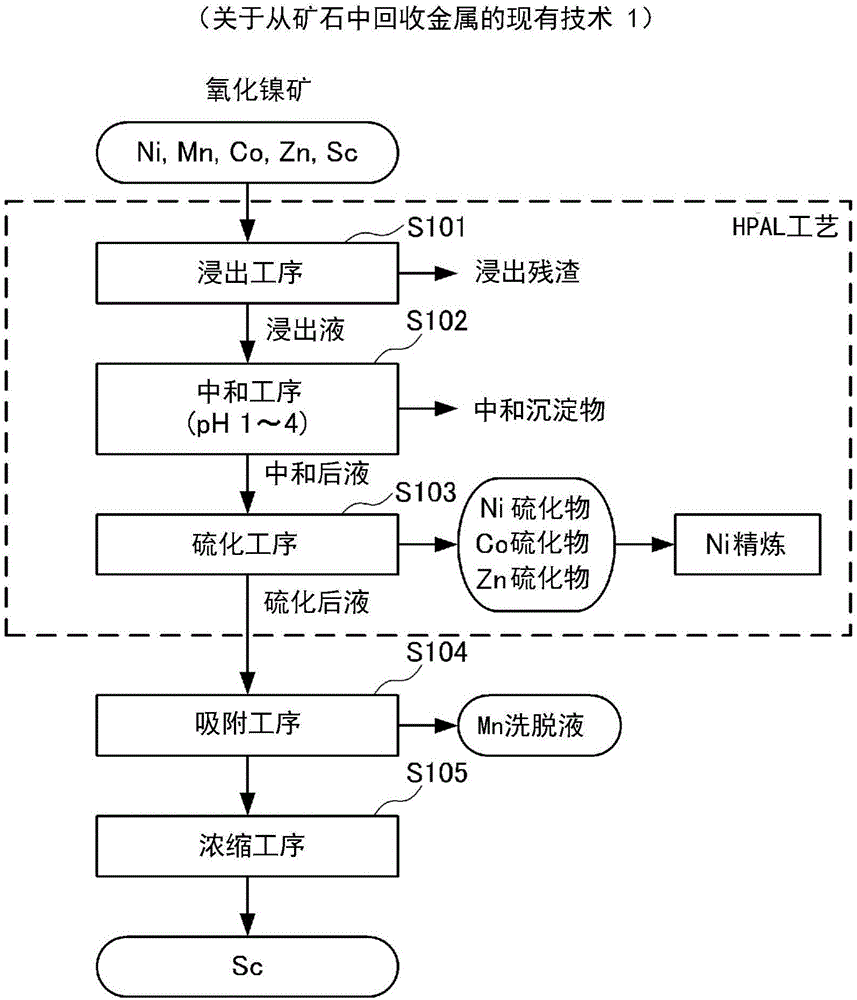

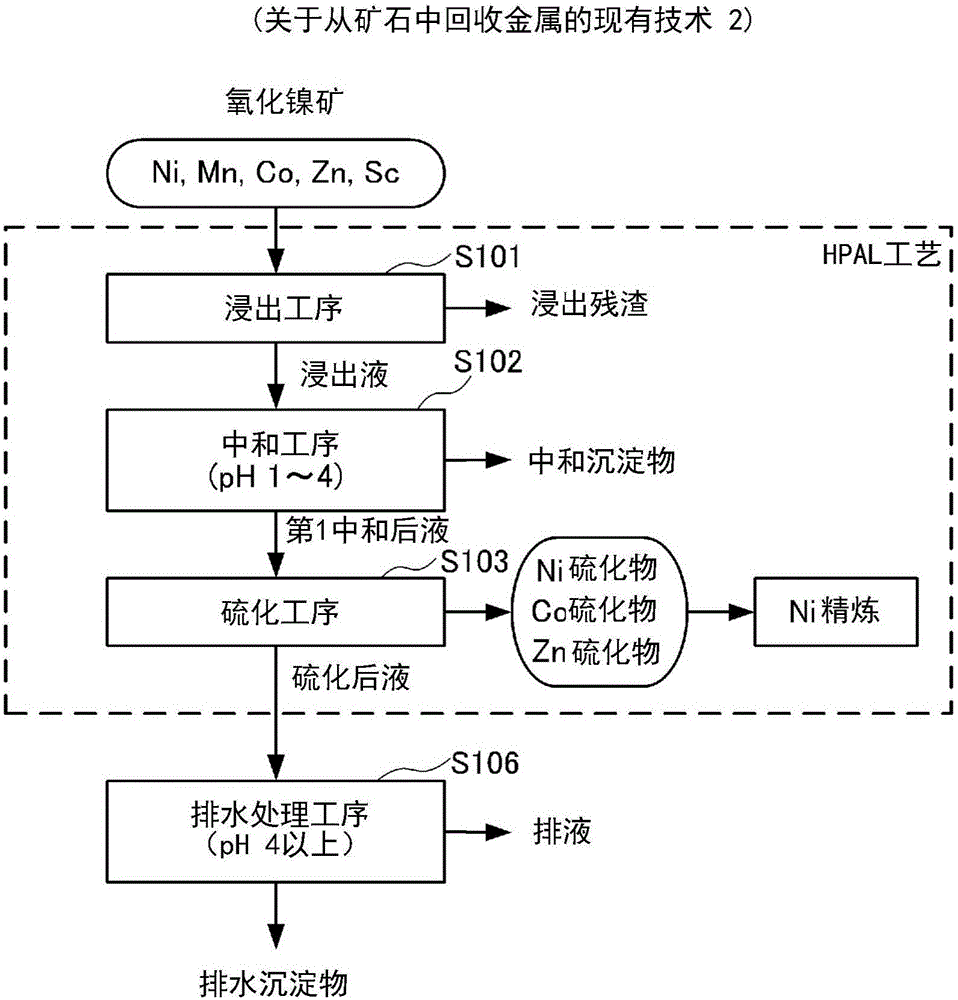

Scandium recovery process

A recovery method, scandium oxide technology, applied in the field of scandium hydroxide, scandium oxide and/or scandium carbonate as resource recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] [Washing of drain sediment]

[0067] The above-mentioned drained sediment was used as a 20% by weight slurry, stirred at room temperature for 30 minutes, and then the washed washing liquid and the washed precipitate were subjected to solid-liquid separation using a suction filter (ヌッチェ) and a filter bottle. Water was added to the washed precipitate again, and re-washed in the same manner as above. Table 3 shows the composition of the rewashed precipitate after washing and rewashing.

[0068] [table 3]

[0069] Composition of precipitate after rewashing (unit: weight %)

[0070] Ni

Fe

Cr

Si

Al

Ca

Mg

mn

sc

0.04

33.00

1.30

3.20

2.10

7.50

0.49

0.07

0.0009

[0071] As can be seen from Table 3, about 90% of the manganese component contained in the neutralized precipitate can be removed by washing and rewashing.

[0072] [Dissolution of precipitate after rewashing]

[0073] A sulfuric acid solutio...

Embodiment 2

[0075] Except that the washing liquid and the washing precipitate were subjected to solid-liquid separation, the washing precipitate was not washed again, and the washing precipitate was directly dissolved in sulfuric acid solution, the same method as in Example 1 was used to obtain scandium Dissolved solution and dissolved residue. This scandium solution was used as a sample of Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com