Method for producing non-orientation electric steel plates with insulation coatings

A technology for oriented electrical steel sheets and manufacturing methods, which is applied to coatings, manufacturing tools, and other manufacturing equipment/tools, can solve the problems of high manufacturing costs and low production efficiency, and achieve improved bonding, good punching properties, and durability good heat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1-6

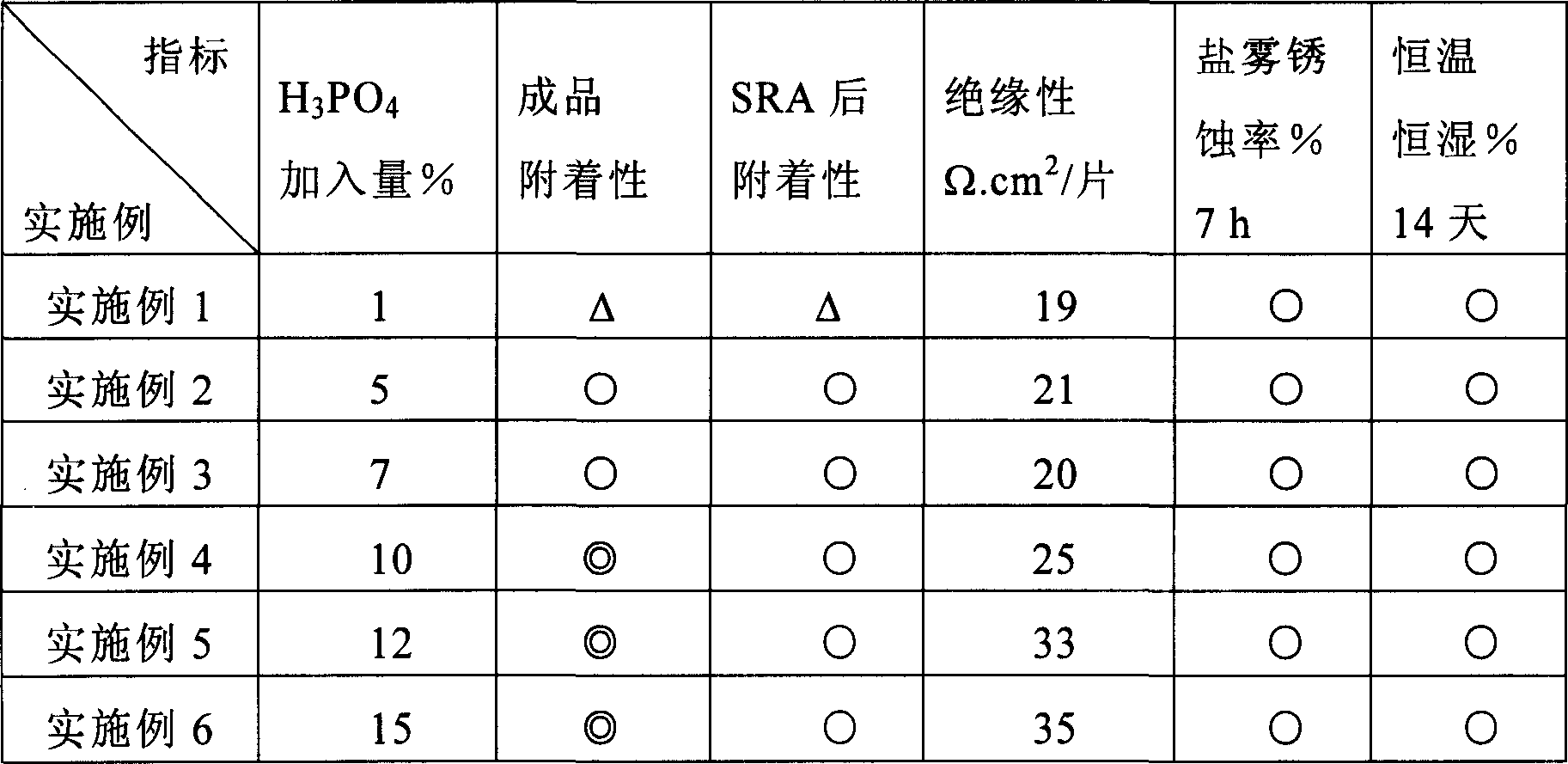

[0035] Example 1-6: Immerse an annealed electrical steel sheet with a thickness of 0.5mm into the following 1%, 5%, 7%, 10%, 12%, 15% and other concentrations of H 3 PO 4 In the solution for a few seconds, after performing post-cleaning, prepare the treatment solution according to the following coating formula:

[0036] a. Chromic acid or chromate containing two or more metals such as Mg, Ca, Zn, etc., with a weight percentage of 2-20%;

[0037] b. Organic resin, the weight percentage is 1-10%;

[0038] c. Reducing agent, the weight percentage is 0.5 to 5%;

[0039] d. Boric acid, the weight percentage is 0.5 to 5%;

[0040] The balance is water.

[0041]The coating is applied on a grooved roller coater, and then it is dried and baked in a baking oven. The baking temperature of the steel plate is controlled at 150~360℃, the baking time is 20~60 seconds, and the thickness of the dry film is controlled at 1.8~2.8. g / m 2 , The results are shown in Table 1.

[0042] Tab...

example 7-12

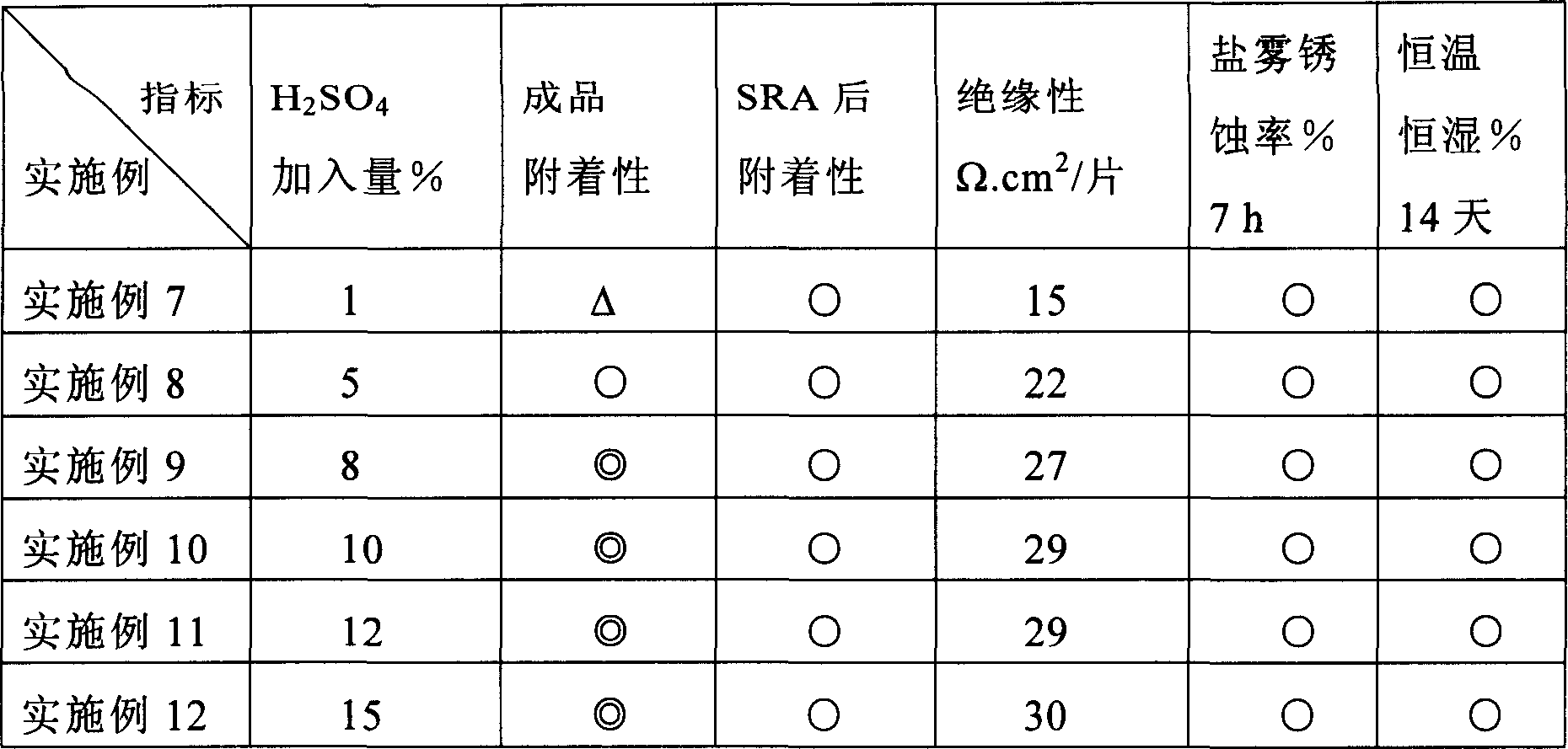

[0045] The 0.5mm thick electrical steel plate is immersed at room temperature and contains 1%, 5%, 8%, 10%, 12%, 15% and other different contents of H 2 SO 4 After drying, prepare the treatment solution according to the same semi-organic thick coating formula of Example 1-6, and apply it on the grooved roller coater, and then enter the baking oven for drying and baking. The temperature of the steel plate is controlled at 150~360℃, the baking time is 20~60 seconds, and the film thickness is controlled at 1.8~2.8g / m 2 , Examples 7-12, the results are shown in Table 2.

[0046] Table 2 The actual performance of the quality index of the insulating coating

[0047]

example 13-17

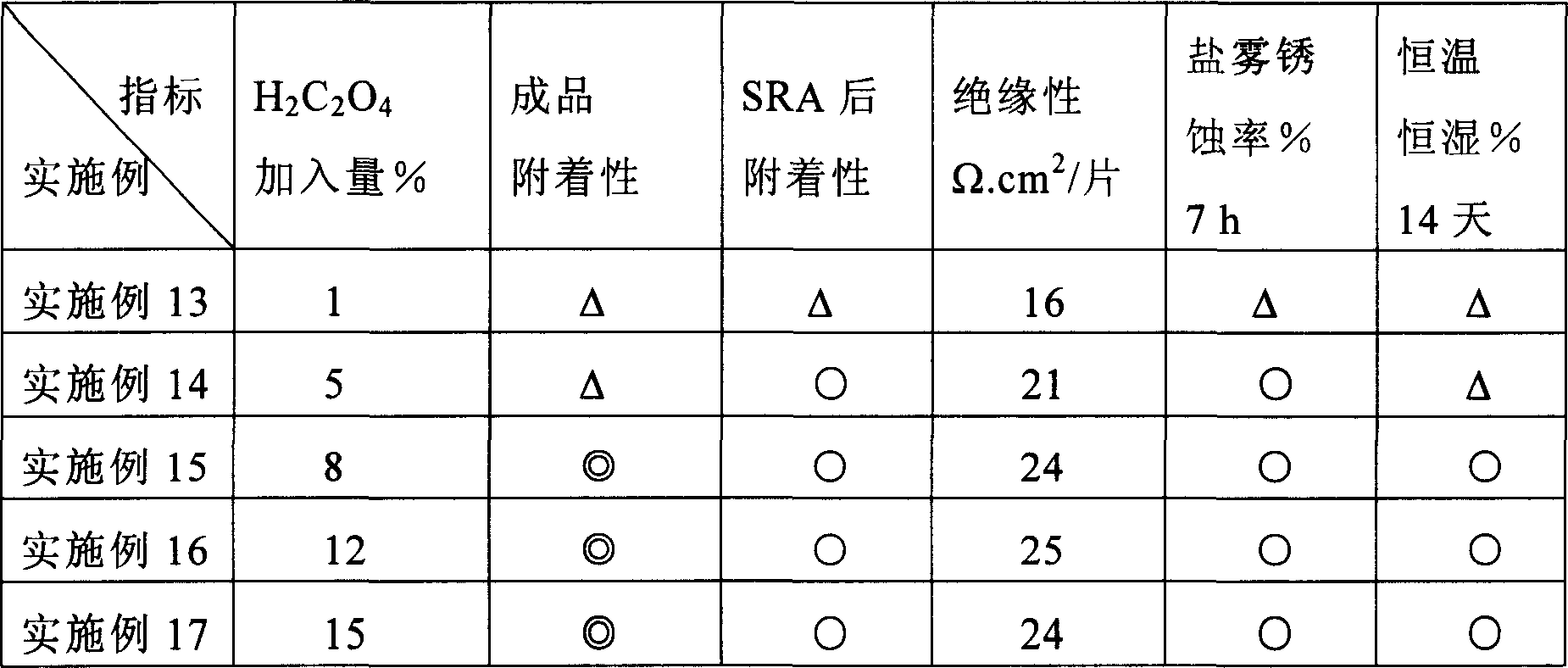

[0049] The 0.5mm thick electrical steel plate is immersed at room temperature and contains 1%, 5%, 8%, 12%, 15% and other different contents of H 2 C 2 O 4 After drying, prepare the treatment solution according to the same semi-organic thick coating formula of Examples 1, 2, and 3, and apply it on the grooved roller coater, and then enter the baking oven for drying and baking. The baking temperature is controlled at 150~360℃, the baking time is 20~60 seconds, and the dry film thickness is controlled at 1.8~2.8g / m 2 , Examples 13-17, the results are shown in Table 3.

[0050] Table 3 Performance of the quality index of insulating coating

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com