Preparation method for nano-titanium dioxide film photocatalyst

A nano-titanium dioxide, photocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of fast formation of titanium gel, complex synthesis methods, large types and quantities of organic reagents, etc. To achieve the effect of delaying hydrolysis and polycondensation reactions, easy control of reaction conditions, and reduction of types and dosages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

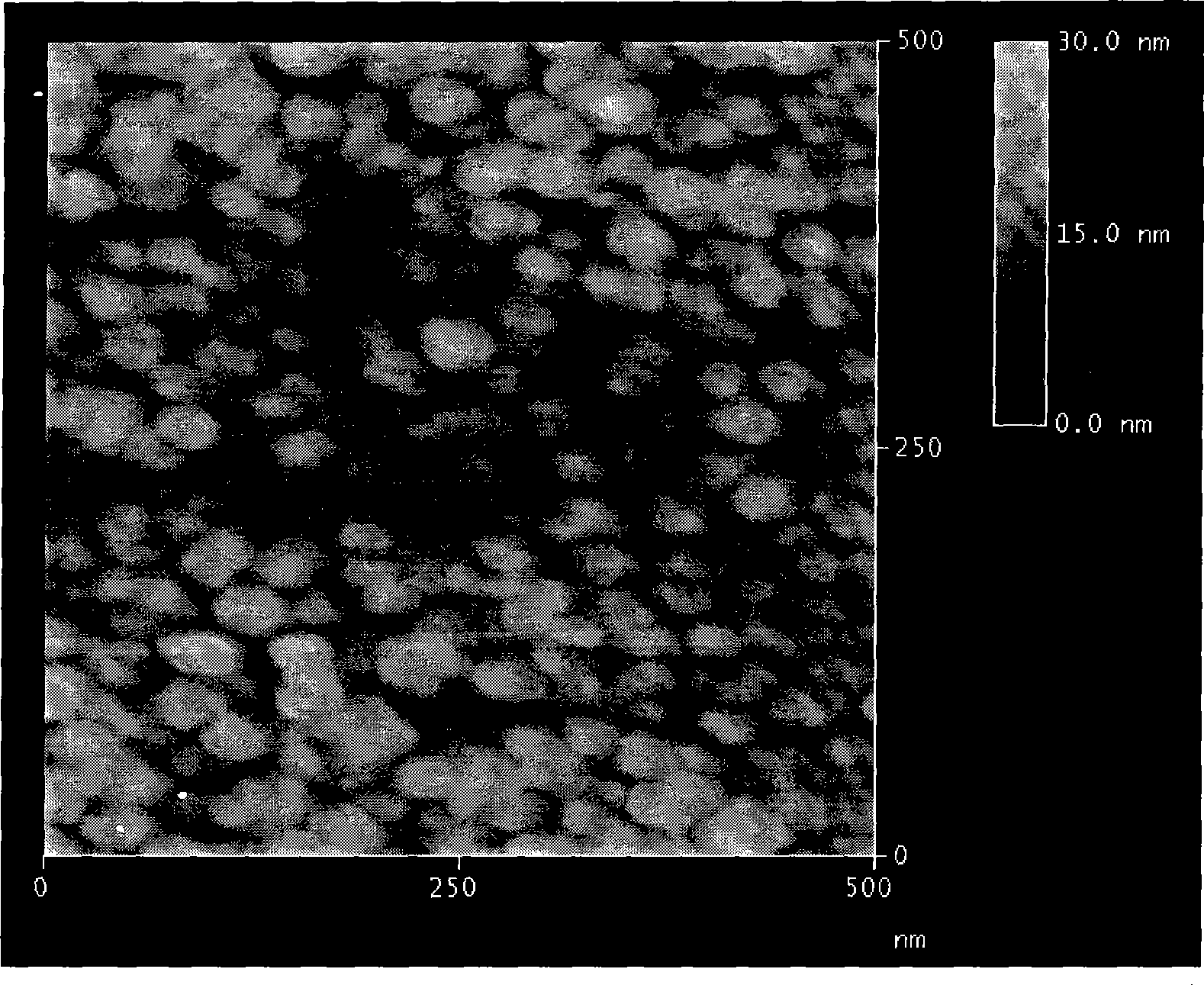

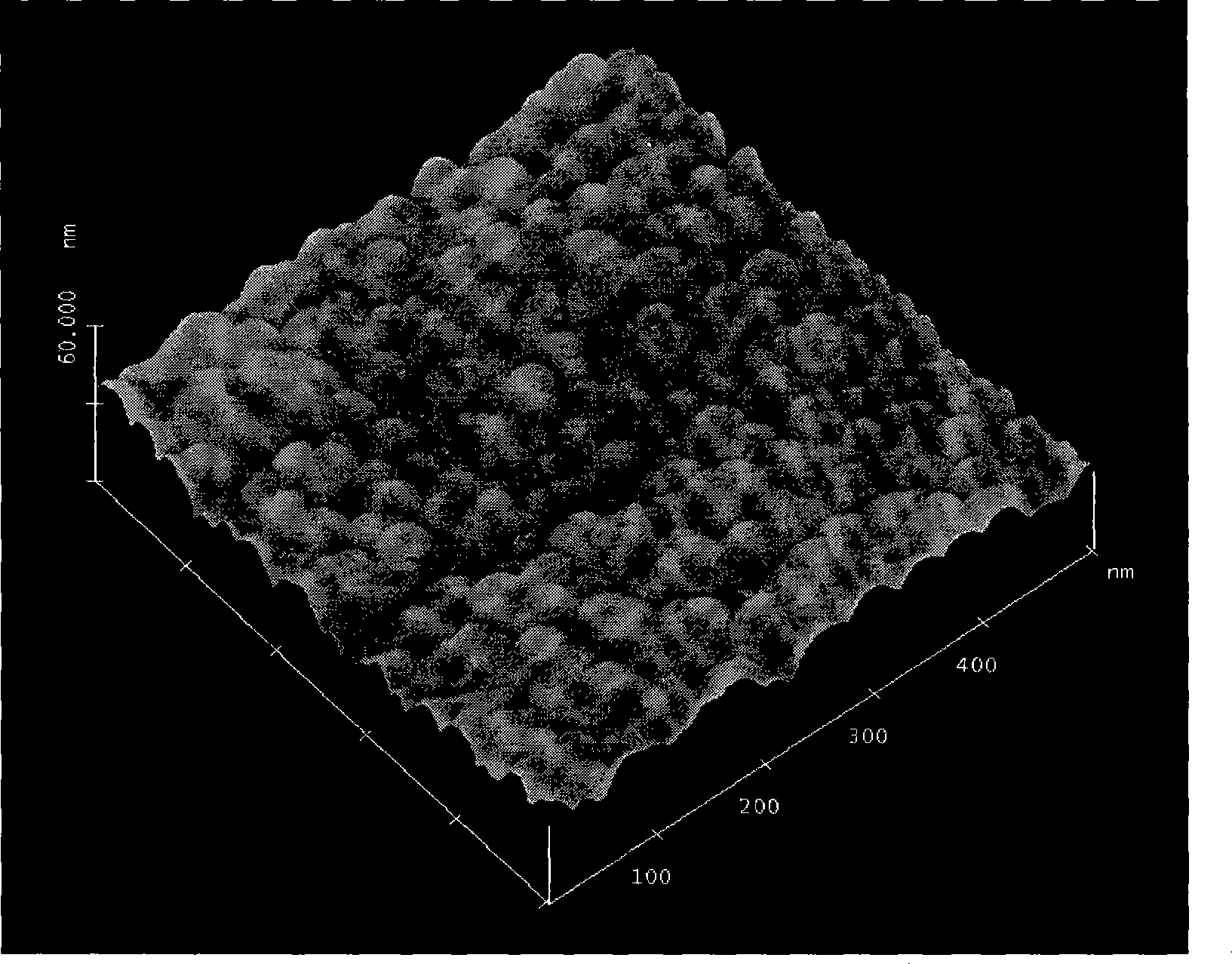

Image

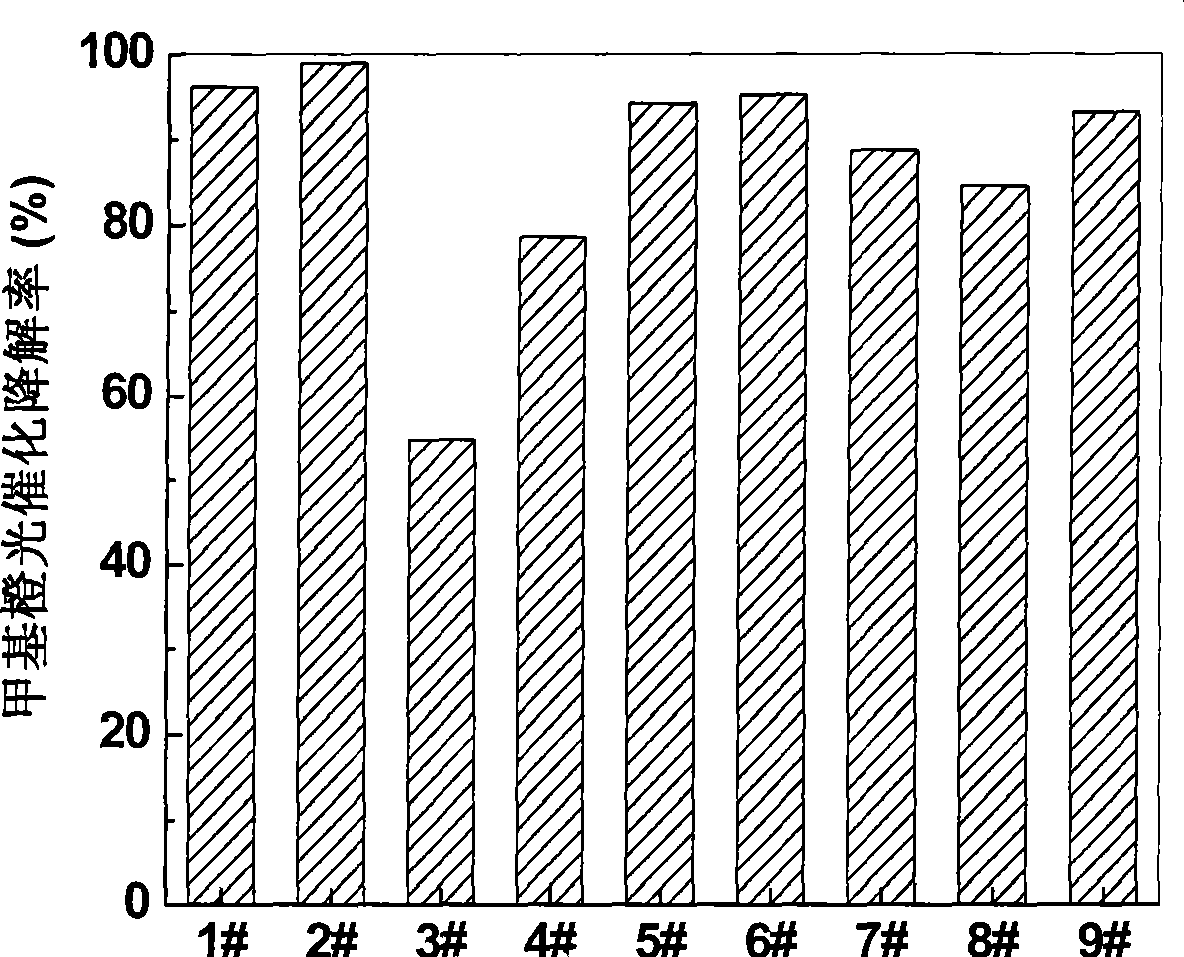

Examples

Embodiment 1

[0019] (1) Add 0.5g of n-butyl titanate dropwise to 5mL of 10% acetic acid solution by volume percentage, and stir continuously for 3h to obtain an acetic acid solution of n-butyl titanate; add 0.1g of non-ionic templating agent (Polyoxyethylene-polyoxypropylene-polyoxyethylene) was dissolved in 5mL of absolute ethanol, stirred until dissolved to obtain an ethanol solution of a non-ionic templating agent, and then added dropwise to the acetic acid solution of n-butyl titanate Stirring was continued for 1 hour to obtain a titanium sol, which was ultrasonically dispersed for 5 minutes, then transferred to an airtight container for aging for 24 hours to obtain a titanium gel.

[0020] (2) Clean the pre-cut ITO coated glass with a size of 12×5.7cm, dry it, immerse it in the titanium gel prepared above for 1min, and dip and pull it to form a film at a pulling speed of 1mm / s. Dry at 120°C for 10 minutes to obtain the precursor membrane.

[0021] (3) The precursor film was calcined ...

Embodiment 2

[0023] (1) Add 2.0g of n-butyl titanate dropwise to 10mL of 50% acetic acid solution by volume percentage, and stir continuously for 8h to obtain the acetic acid solution of n-butyl titanate; add 0.3g of nonionic template (Polyoxyethylene-polyoxypropylene-polyoxyethylene) was dissolved in 5mL of absolute ethanol, stirred until dissolved to obtain an ethanol solution of a non-ionic templating agent, and then added dropwise to the acetic acid solution of n-butyl titanate Stirring was continued for 3 hours to obtain a titanium sol, which was ultrasonically dispersed for 5 minutes, and then transferred to an airtight container for aging for 48 hours to obtain a titanium gel.

[0024] (2) Clean the pre-cut ITO coated glass with a size of 12×5.7cm, dry it, immerse it in the titanium gel prepared above for 5min, dip and pull it into a film at a pulling speed of 4mm / s, and Dry at 60°C for 360 minutes to obtain the precursor membrane.

[0025] (3) The precursor film was calcined at a ...

Embodiment 3

[0027] (1) Add 5.0g of n-butyl titanate dropwise to 100mL of 10% acetic acid solution by volume, and stir continuously for 6h to obtain the acetic acid solution of n-butyl titanate; add 0.3g of nonionic template (Polyethylene glycol) was dissolved in 5 mL of absolute ethanol, stirred until dissolved to obtain an ethanol solution of a non-ionic template agent, and then added dropwise to the acetic acid solution of n-butyl titanate and continued to stir for 12 hours to obtain a titanium sol , after ultrasonically dispersing the titanium sol for 10 min, transfer it to an airtight container and age it for 1 h to obtain a titanium gel.

[0028] (2) Clean the pre-cut ITO coated glass with a size of 12×5.7cm, dry it, immerse it in the titanium gel prepared above for 10 minutes, dip and pull it at a pulling speed of 4mm / s to form a film, and Dry at 120°C for 10 minutes to obtain the precursor membrane.

[0029] (3) The precursor film was calcined at a high temperature of 250° C. for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com