Aluminum bar low-bar-level storage frame

A material storage rack and aluminum rod technology, which is used in furnaces, lighting and heating equipment, furnace components, etc., can solve the problem of inconvenient rod production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

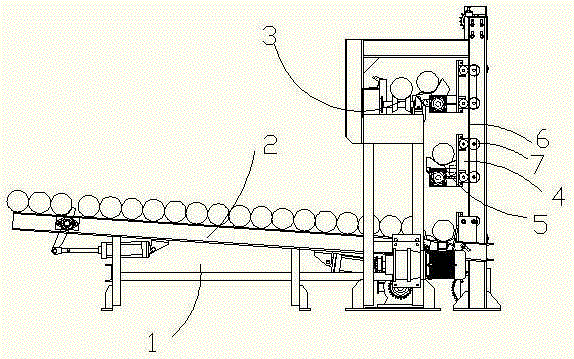

[0013] Such as figure 1 As shown, a storage rack with low rod position for aluminum rods includes a furnace rack 1, and a material rack 2 is arranged obliquely inside the furnace rack 1, and the lower end of the material rack 2 is a discharge port. An aluminum rod lifting mechanism is also provided to slide along the up and down direction. The furnace frame 1 is provided with an aluminum rod outlet, and the aluminum rod outlet is located above the discharge port of the material rack 2. The aluminum rod An aluminum rod conveying roller 3 is provided at the exit, and the aluminum rod lifting mechanism includes a sliding frame 4, a V-shaped aluminum rod turni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com