Smoke generating device for induction heating in folding air passage

A smoking device and induction heating technology, applied in the direction of tobacco, etc., can solve the problems of heat shrinkage of the support section material, low heat capacity, excessive relative temperature difference, etc., and achieve increased length, uniform baking, and reduced axial direction. effect of length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

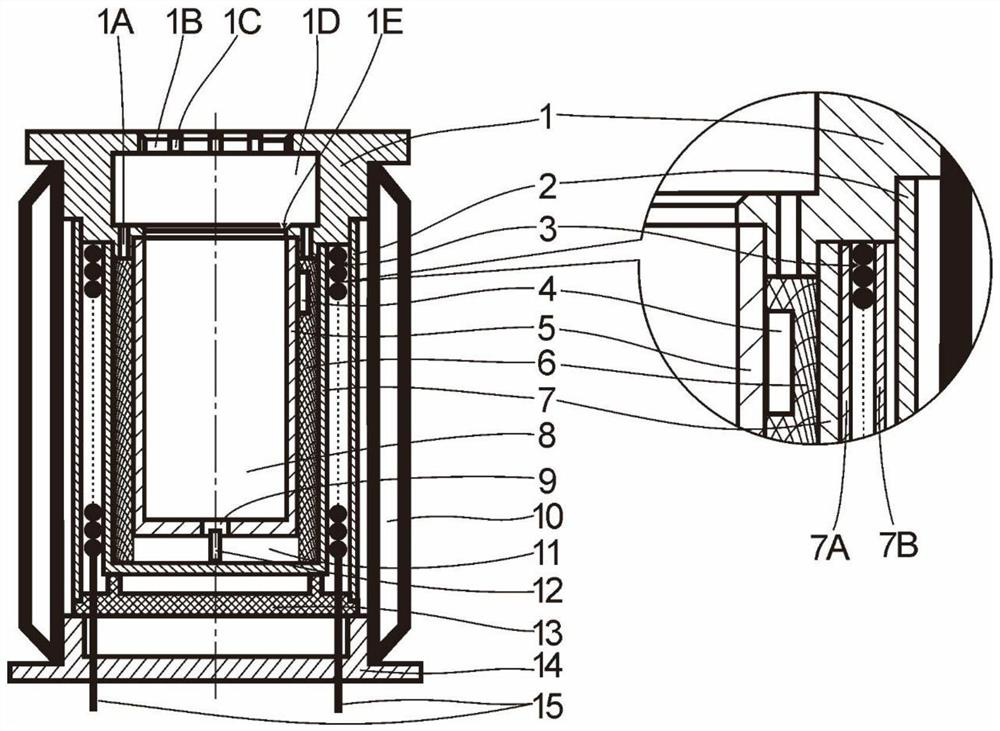

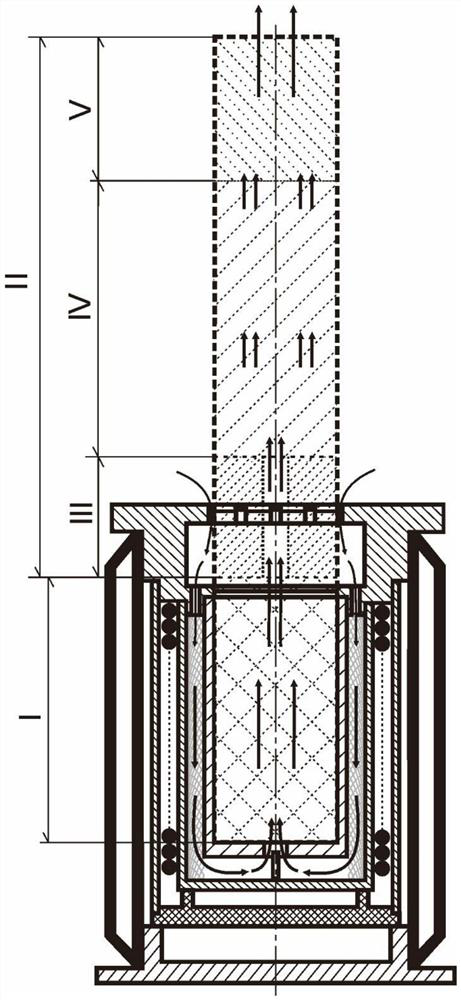

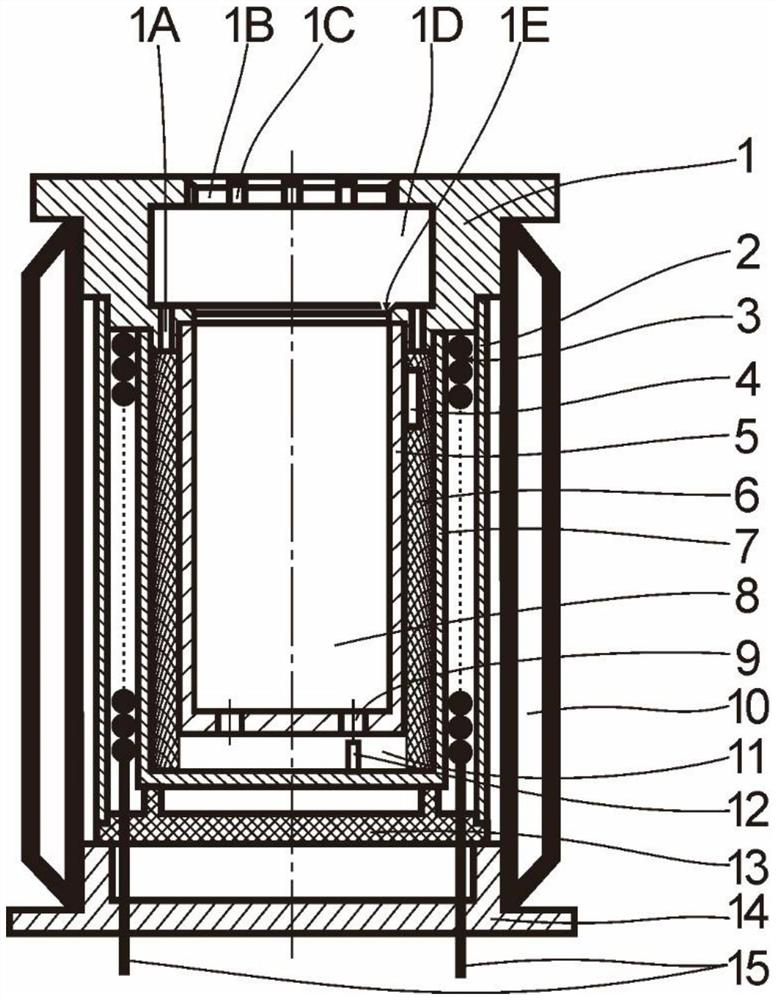

[0066] Such as figure 1 , a sensor device in the folded airway includes: a cigarette introduction tube 1, an electromagnetic isolating ring 2, an induction coil 3, a first temperature measuring element 4, a heating cup 5, a heating element 6, a magnetically conductive sealing body 7, an insulating and heat insulating Layer 7A, insulation and high temperature resistant wrapping layer 7B, cigarette accommodating chamber 8, air intake hole 9, heat insulation chamber 10, soaking chamber 11, second temperature measuring element 12, heat insulation seat 13, base 14, connecting wire 15.

[0067] Wherein, the cigarette introduction pipe 1 is arranged at the upper end of the smoking device, which is a hollow pipe structure, and the inner cavity is a mixing chamber 1D, and the center of the upper end of the cigarette introduction pipe 1 is a first introduction hole 1B, the center of the lower end is the second introduction hole 1E, the outer ring of the first introduction hole 1B is pro...

Embodiment 2

[0091] The difference between this embodiment and Embodiment 1 is that the cup bottom of the heating cup 5 has a plurality of circularly distributed air inlets 9, and the schematic diagram of the longitudinal section of the smoking device is as follows: image 3 . The second temperature-measuring element 12 is arranged in the uniform heat chamber 11 formed between the bottom of the heating cup 5 and the bottom of the magnetic seal 7, and is facing or biased to any one of the air inlets 9 (with An air intake hole 9 represents on the far right). At this time, in the air passage, heated air enters from the uniform heat chamber 11 into the cigarette accommodating chamber 8 through a plurality of annularly distributed air intake holes 9, and the degree of dispersion of the air is higher. The heating effect is more uniform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com