Cigarette roaster box

A technology of flue-cured tobacco box and cigarette body, applied in the field of flue-cured tobacco box, can solve the problem of low heat utilization efficiency, and achieve the effects of improving heat utilization rate, large smoke volume and sufficient baking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

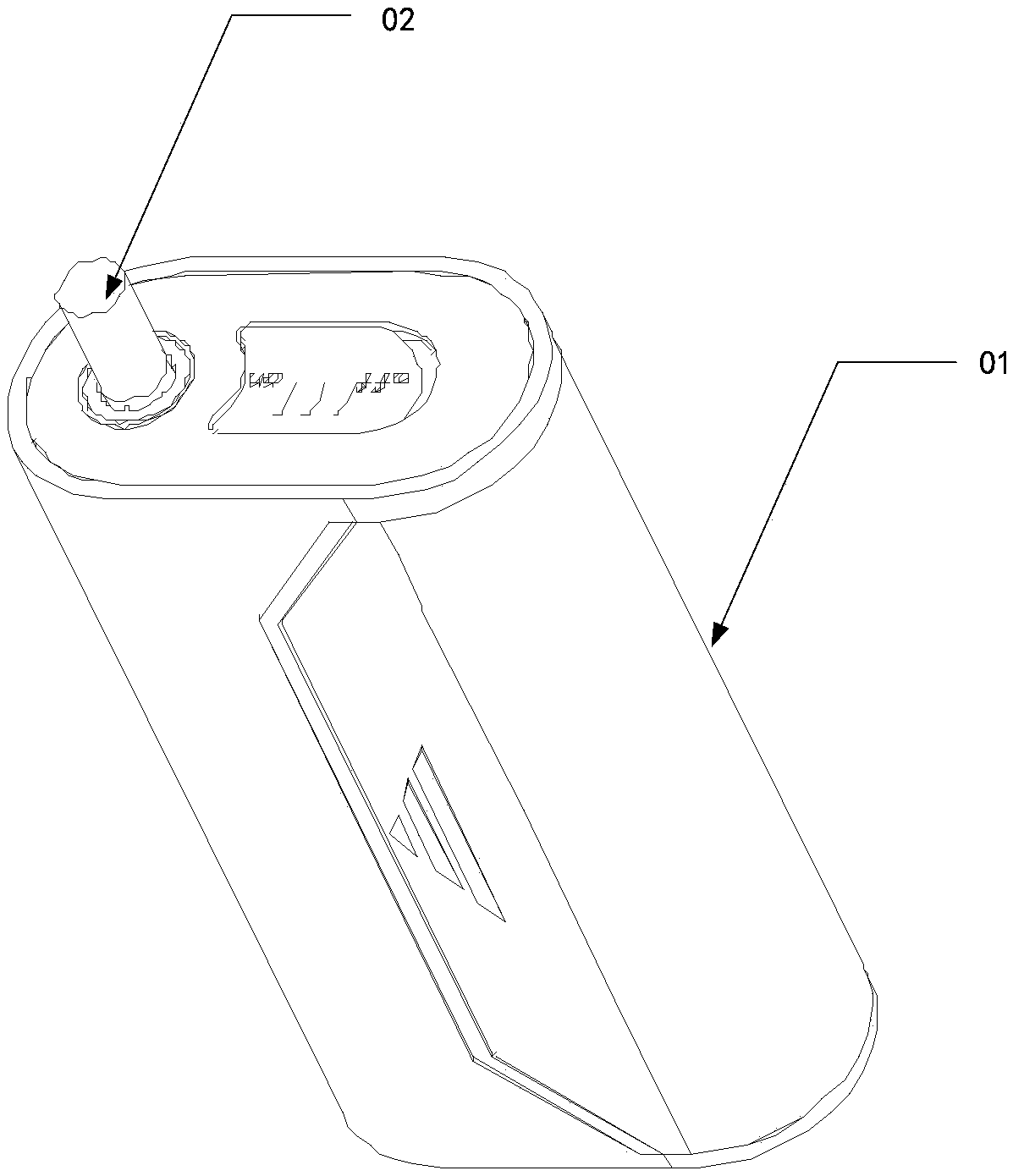

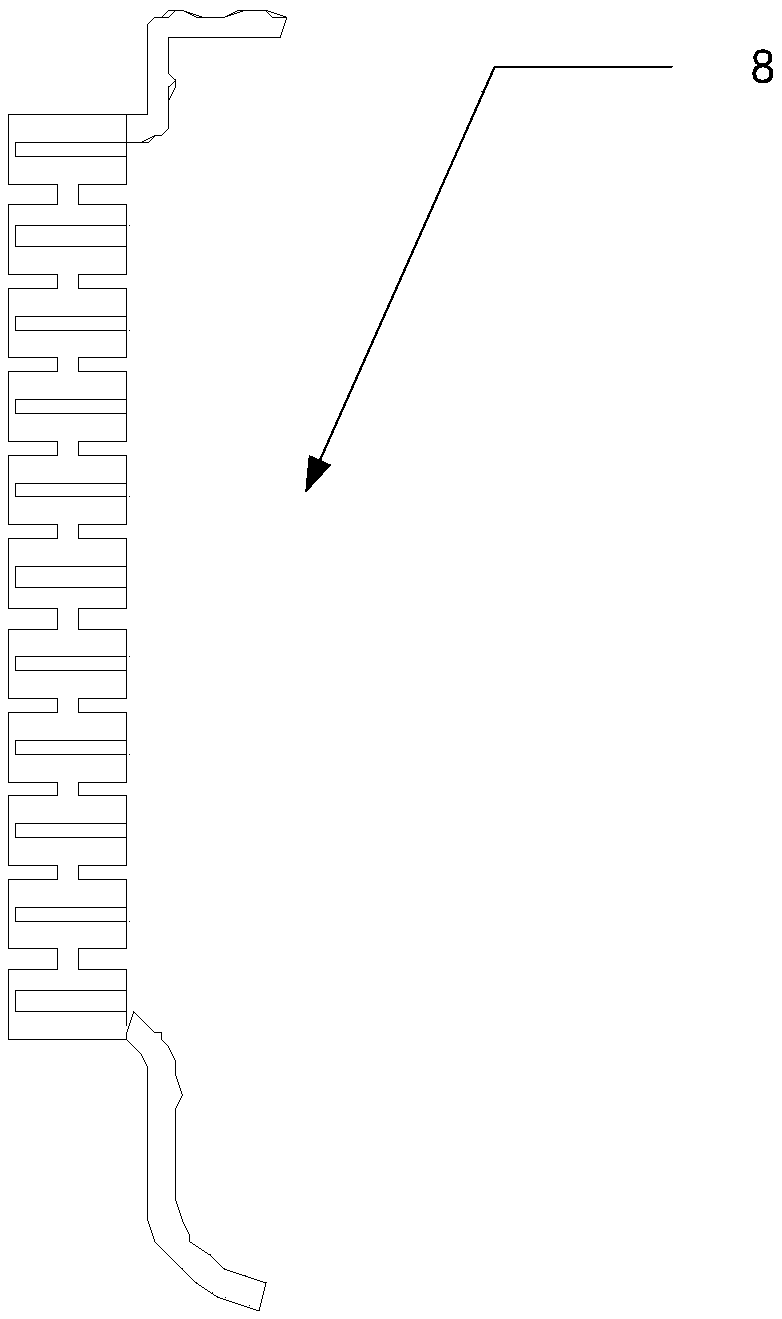

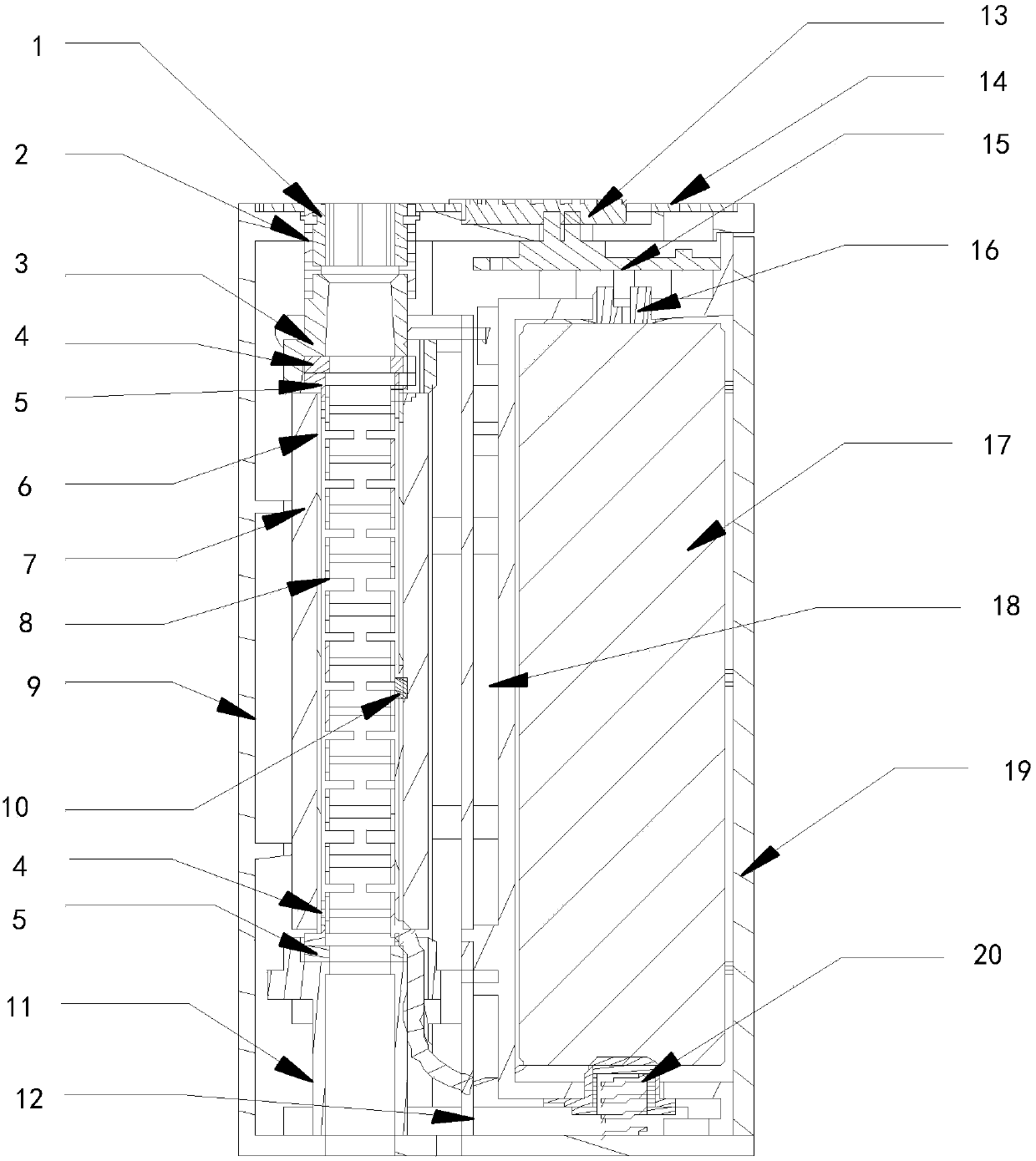

[0023] Please refer to Figure 1 to Figure 3 , Figure 1 to Figure 3 It shows the flue-cured tobacco box proposed by a preferred embodiment of the present invention, wherein, figure 1 It is a schematic diagram of the three-dimensional structure of a preferred embodiment of the flue-cured tobacco box of the present invention, figure 2 It is a structural schematic diagram of the heat pipe in the preferred embodiment of the flue-cured tobacco box of the present invention, image 3 It is a schematic cross-sectional view of the flue-cured tobacco box of the present invention.

[0024] Such as Figure 1 to Figure 3 As shown, the preferred embodiment of the flue-cured tobacco box of the present invention includes a box body 9, and a heating device for heating the smoke body 01 of a cigarette is installed in the box body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com