Composite material for producing bakeware and bakeware produced with the material

A technology of composite materials and baking trays, applied in the direction of baking cans, etc., can solve the problems of insufficient baking of food, high cost, and affecting the taste of food, and achieve the effect of good rigidity, low cost, and improved taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] The present invention is used for making the composite material of bakeware, and described composite material is made up of following components according to mass percentage:

[0025] Liquid crystal polymer LCP 40~65% Polyethersulfone PES 4~40%

[0026] Polytetrafluoroethylene PTFE 1~15% Glass fiber 15~45%

[0027] Mica 0.5~5% Calcium carbonate 2~10%

[0029] In this embodiment, the composite material used to make the bakeware of the present invention consists of the following components in terms of mass percentages:

[0030] Liquid Crystal Polymer LCP 50% Polyethersulfone PES 5%

[0031] Polytetrafluoroethylene PTFE 5% Glass Fiber 30%

[0032] Mica 2% Calcium Carbonate 3% Talc 5%

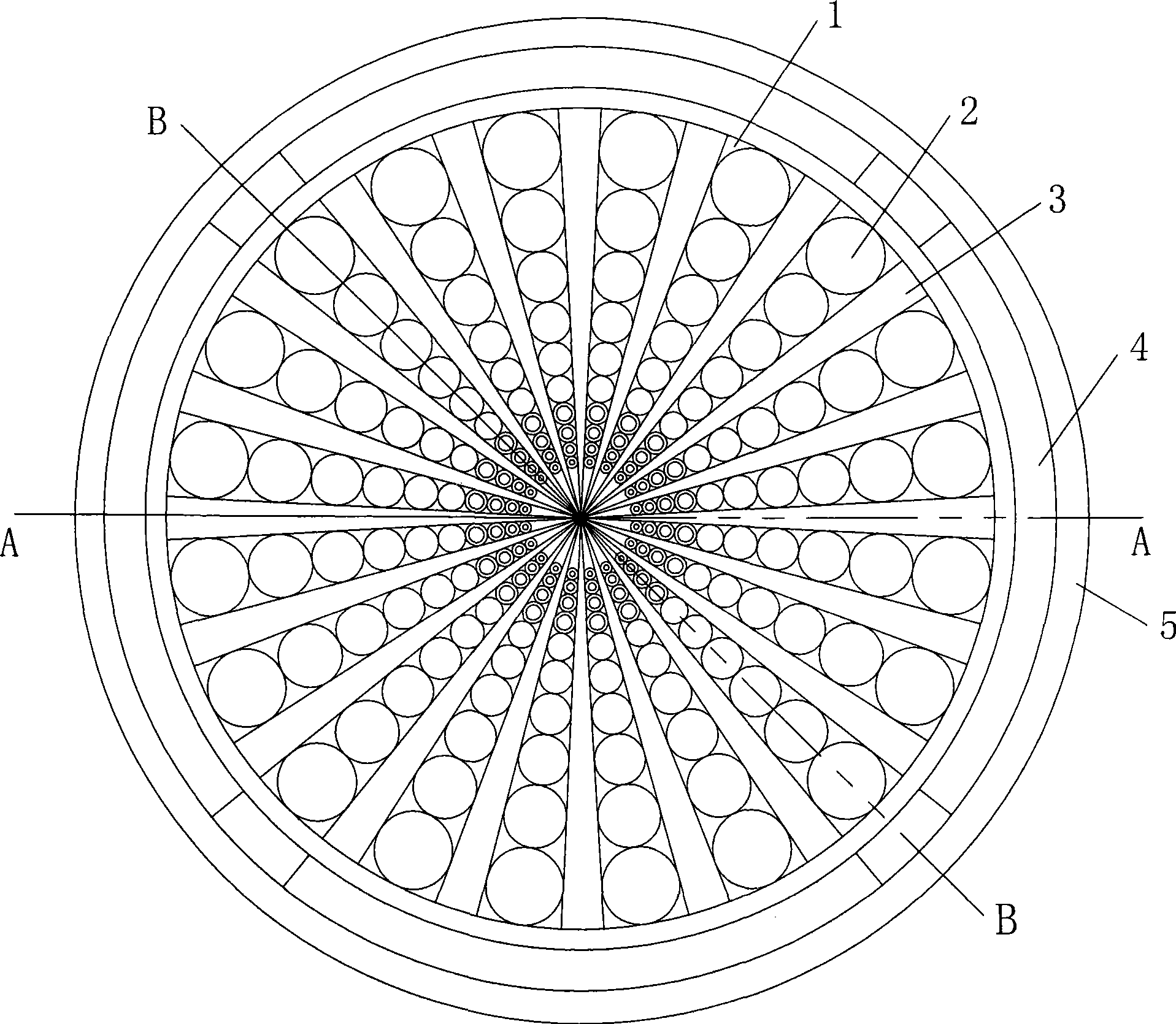

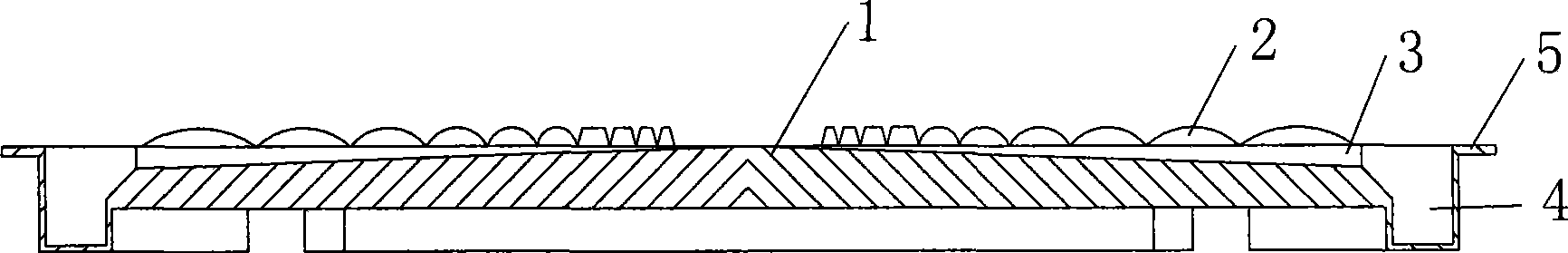

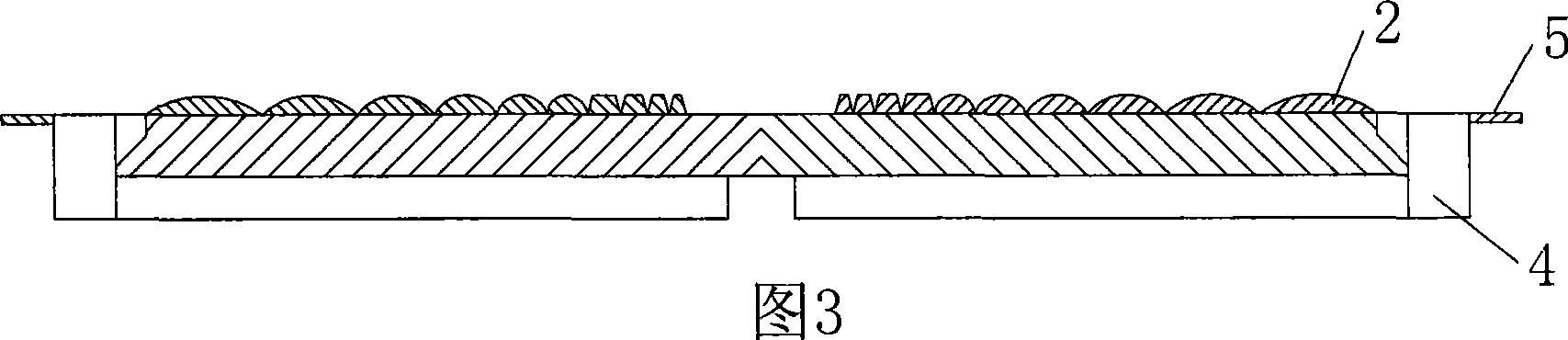

[0033] The baking pan made of the above-mentioned materials in the present invention has a structural schematic diagram as figure 1 , 2 As shown in , 3, the baking pan 1 is made into a plate shape, and the upper surface of the baking pan 1 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com