Temperature-changeable baking method of orange osmanthus oolong tea

A roasting method and technology of oolong tea, applied in the tea treatment before extraction, etc., can solve the problems such as the impact on the quality of Dangui oolong tea, and achieve the effect of distinctive quality characteristics, strong floral fragrance, and sufficient heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A variable temperature roasting method for osmanthus oolong tea, comprising the steps of:

[0020] (1) Spread the osmanthus oolong tea evenly in the baking frame, the thickness of the spread leaves is 1-1.5cm;

[0021] (2) First bake at a high temperature of 120°C for 20 minutes to remove the green grass and roughness remaining in the raw tea.

[0022] (3) Slowly roast for 130 minutes at a low temperature of 90° C. to transform the quality of the tea leaves.

[0023] (4) Finally, increase the aroma at a high temperature of 120°C for 30 minutes to produce fire incense.

[0024] The roasted tea leaves are cooled and evenly stacked, and subjected to sensory evaluation. The particles are compact, the color sand is green and slightly red, even and relatively clean; the fragrance of flowers is strong and the fire is strong; The soup color is golden and bright; the leaf bottom is thick, soft and bright, relatively uniform, with slightly red edges and other quality characteri...

Embodiment 2

[0026] A variable temperature roasting method for osmanthus oolong tea, comprising the steps of:

[0027] (1) Spread the osmanthus oolong tea evenly in the baking frame, the thickness of the spread leaves is 1-1.5cm.

[0028] (2) In the high-temperature impurity removal stage, bake at 110°C for 30 minutes.

[0029] (3) In the low-temperature slow-baking stage, bake at 90°C for 140 minutes.

[0030] (4) Bake at 130°C for 10 minutes in the stage of high-temperature aroma enhancement.

[0031] The roasted tea leaves are cooled and evenly stacked, and subjected to sensory evaluation. The particles are compact, the color sand is green and slightly red, even and relatively clean; the fragrance of flowers is strong and the fire is strong; The soup is golden and bright; the leaf bottom is thick, soft and bright, relatively even, with slightly red edges.

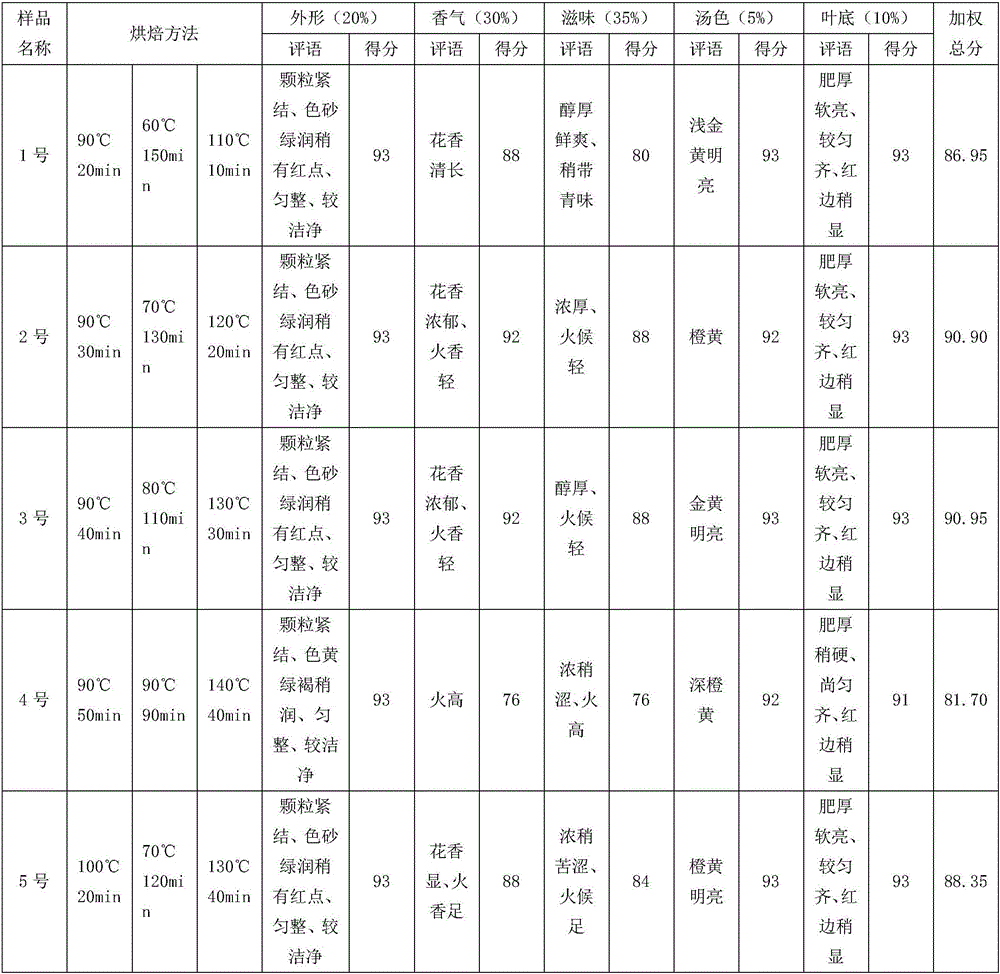

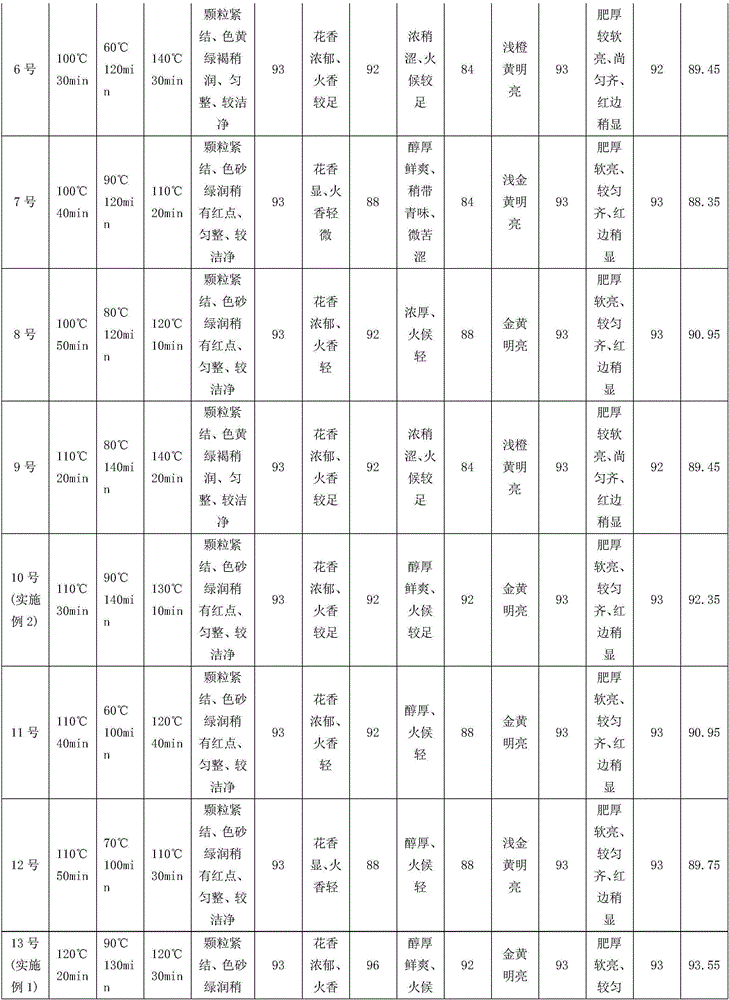

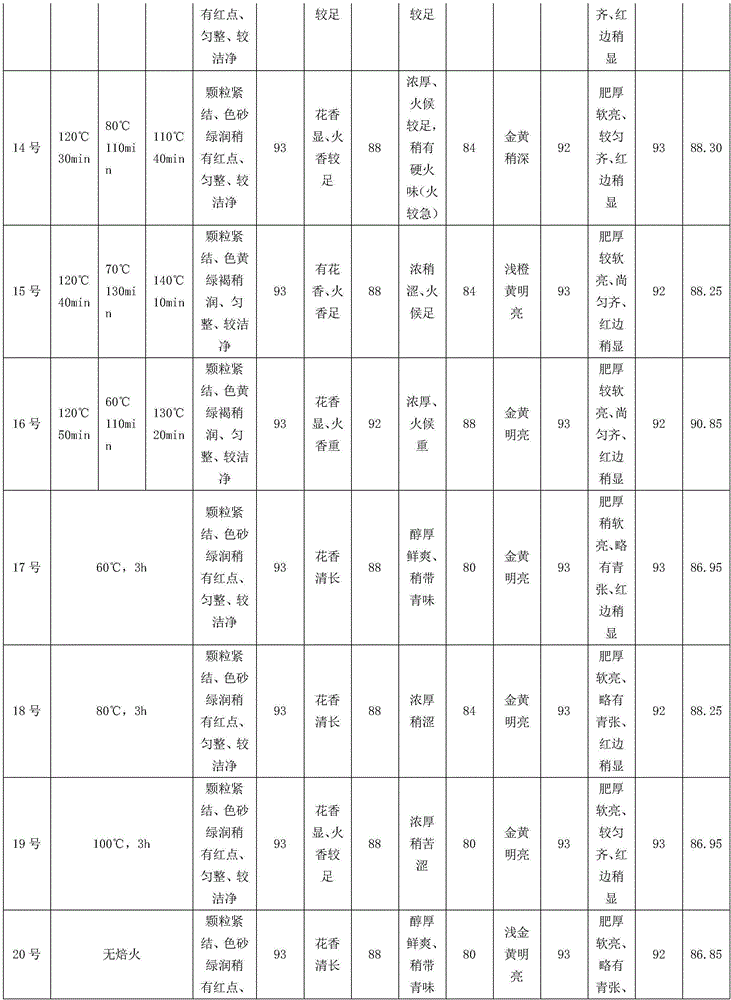

[0032] The applicant has carried out sensory evaluation on the Dangui oolong tea prepared by the method of the above-mentioned E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com