Baking system in LED (Light Emitting Diode) packaging

An LED packaging and oven technology, which is applied in the field of baking systems, can solve problems such as uneven oven temperature, and achieve the effects of improving baking effect, performance, and baking speed and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

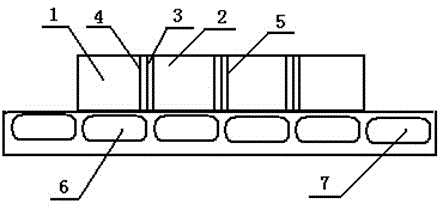

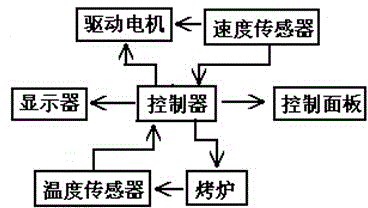

[0036] Specific embodiment one, such as figure 1 As shown, a baking system in LED packaging includes a controller, an oven, a transmission device, and several temperature sensors. The oven includes multiple temperature zones, and a temperature sensor is arranged in each temperature zone. The controller They are respectively connected to the oven, the transmission device, and several temperature sensors. A heat insulation device is provided between two adjacent temperature zones of the oven. Taking the first temperature zone 1 and the second temperature zone 2 as examples, the first temperature zone A heat insulation device 3 is set between zone 1 and the second temperature zone 2, and a first heating plate 4 and a second heating plate 5 are respectively set on both sides of the heat insulation device 3, wherein the first heating plate 4 is located in the first temperature zone 1 , the second heating plate 5 is located in the second temperature zone 2 .

[0037] The transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com