SC fast-connecting ceramic ferrule

A ceramic ferrule, quick-connect technology, applied in the field of optical fiber communication, can solve problems such as deficiencies, and achieve the effect of good anti-drop performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

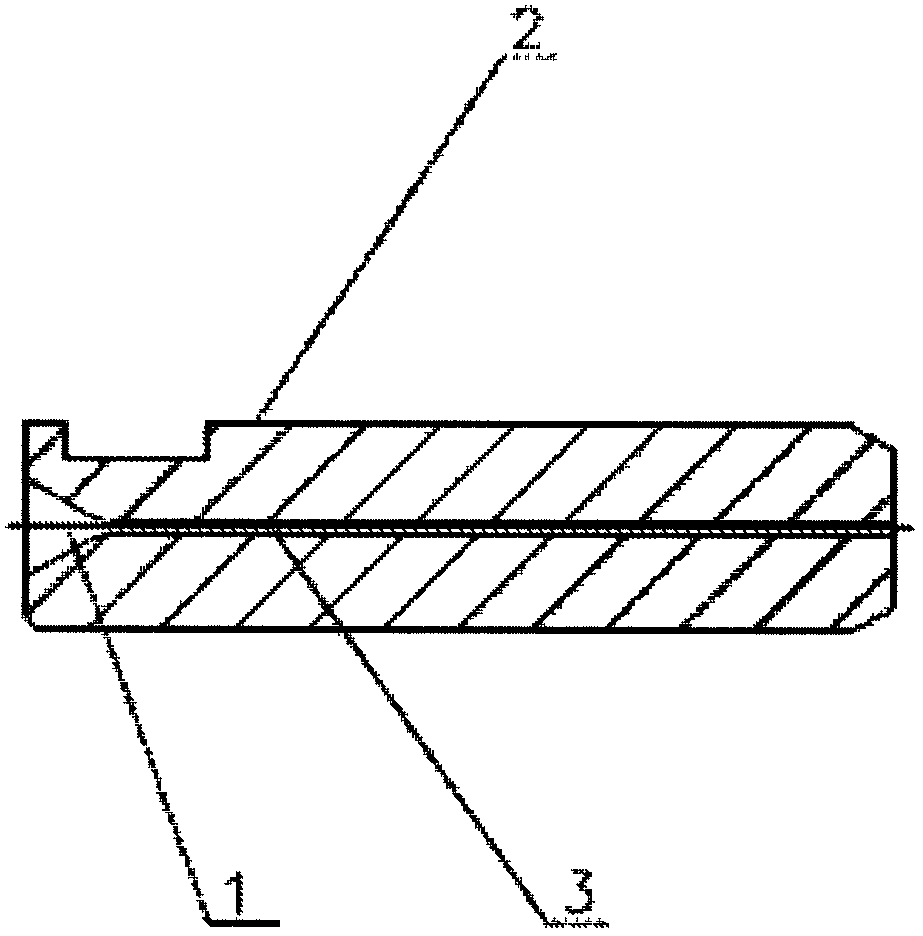

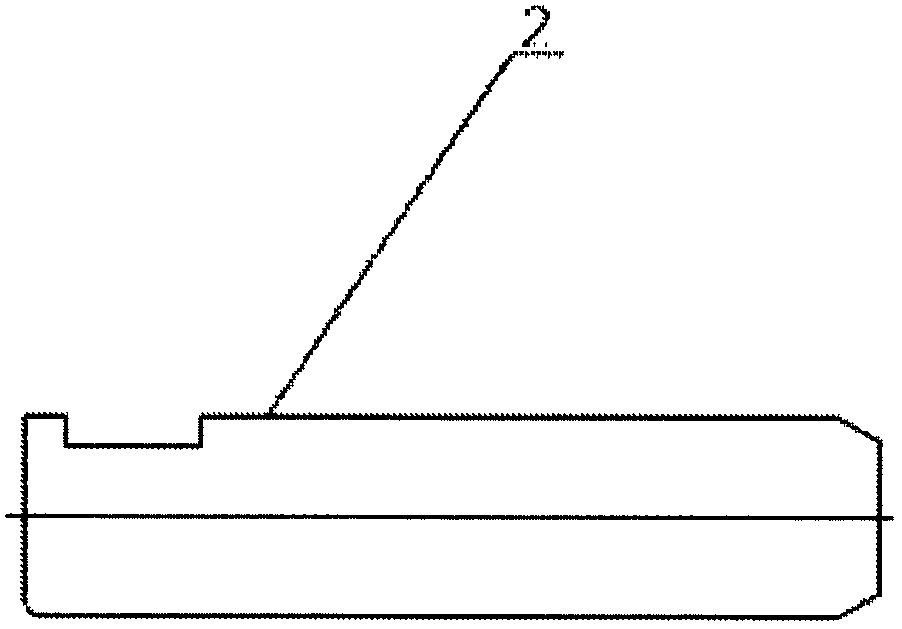

[0028] Such as figure 1 , figure 2 As shown, a SC quick-connect ceramic ferrule, the main body 2 of the ceramic ferrule is cylindrical; wherein, the inner hole 3 of the other end of the ceramic ferrule is provided with a conical groove 1, and the tapered end The angle between the oblique length of the head and the axis of the ferrule is 30°. The length of the ceramic ferrule is 10.50±0.05mm, the inner diameter is between 0.1253-0.1263mm, the outer diameter is 2.4990±0.0005mm, the concentricity is not greater than 1μm, and the cylinder is a 2.0mm wide positioning groove;

[0029] It can be seen from the above technical scheme of an SC quick-connect ceramic ferrule of the present invention that: through the conical grooves 1 at 3 places in the inner hole of one end of the ceramic ferrule, the optical coupling loss of the ferrule is small, The connection and positioning are accurate, easy to use, beautiful in appearance, stable in performance, and can greatly improve the trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Concentricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com