Flange convenient to detach and install

A technology of flanges and flange pieces, which is applied in the field of flanges that are easy to disassemble and assemble, and can solve problems such as time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

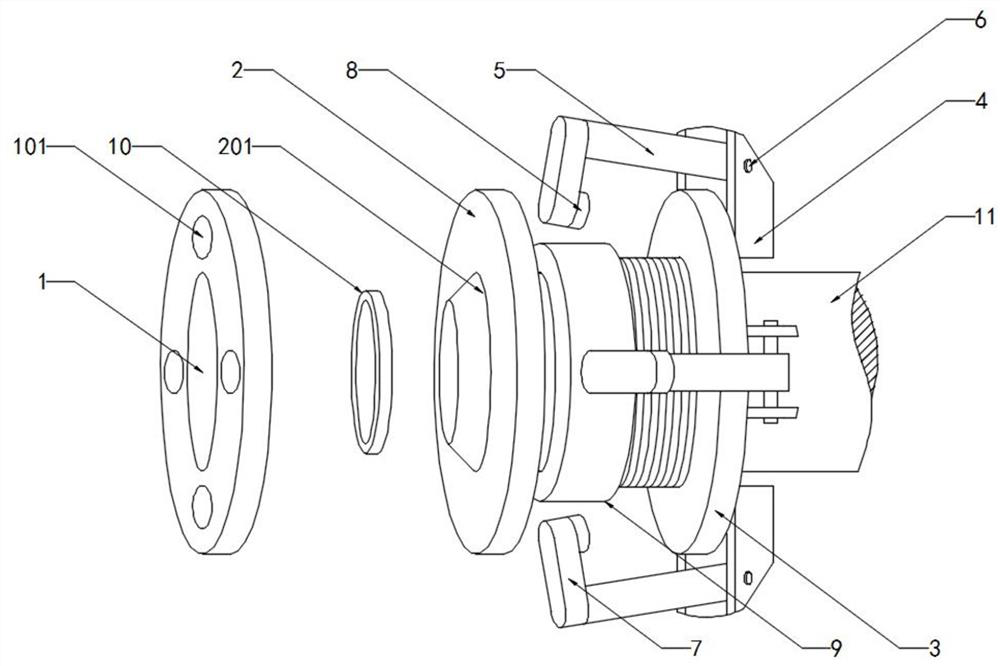

[0027] see Figure 1-3 , including a first flange piece 1, a second flange piece 2 and a pipe 11 fixedly connected to the second flange piece 2, a cylindrical groove 101 is provided on the side wall of the first flange piece 1 away from the second flange piece 2 , a positioning pin 8 is inserted into the cylindrical groove 101 and the length of the positioning pin 8 is less than the depth of the cylindrical groove 101, the pipe 11 is provided with a fixed ring 3, and the fixed ring 3 is fixedly connected to the side away from the second flange 2 The hinge seat 4 is hinged with a pull rod 5 through a rotating shaft 6, the rotating shaft 6 on the hinge seat 4 is located outside the fixed ring 3, the end of the pull rod 5 is fixedly connected with a connecting piece 7, and on the side where the connecting piece 7 is connected with the pull rod 5 Fixedly connected with a positioning pin 8, when the positioning pin 8 is inserted into the inside of the cylindrical groove 101, the pu...

Embodiment 2

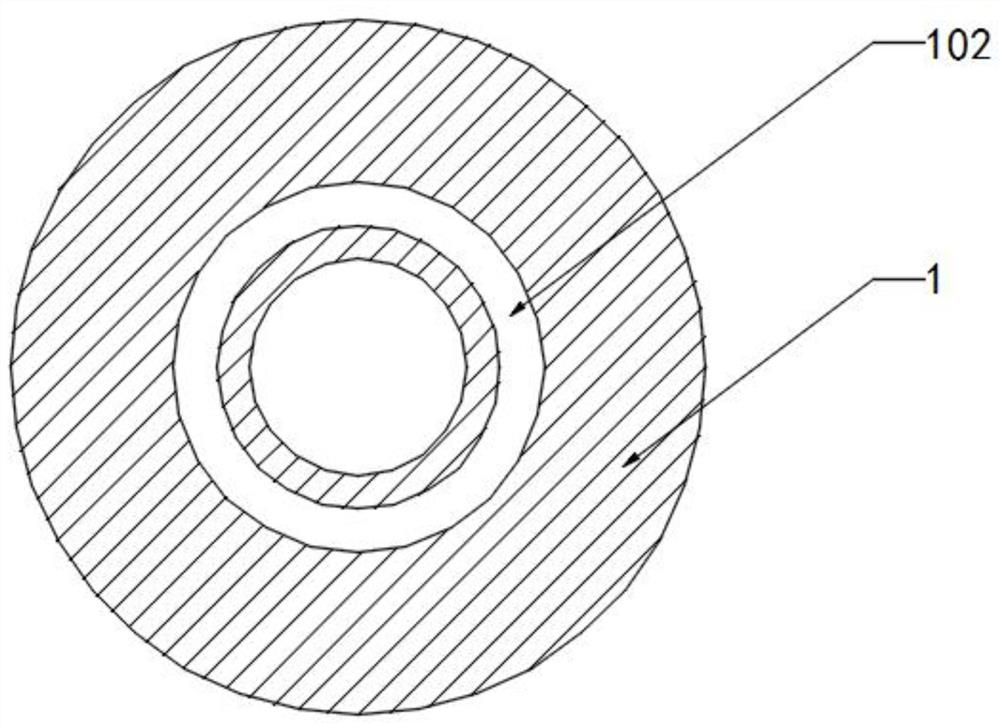

[0029] see Figure 1-3 , the second flange piece 2 has a tapered ring 201 on the side wall close to the first flange piece 1, and the first flange piece 1 has a circular groove 102 on the side wall close to the second flange piece 2, and the tapered ring 201 is inserted into the inside of the ring groove 102, the ring groove 102 has a backing ring 10, the tapered ring 201 abuts against the side wall of the backing ring 10, and the first flange piece 1 and the second flange piece 2 are press fit , so that the connection of the pipeline 11 has better sealing performance.

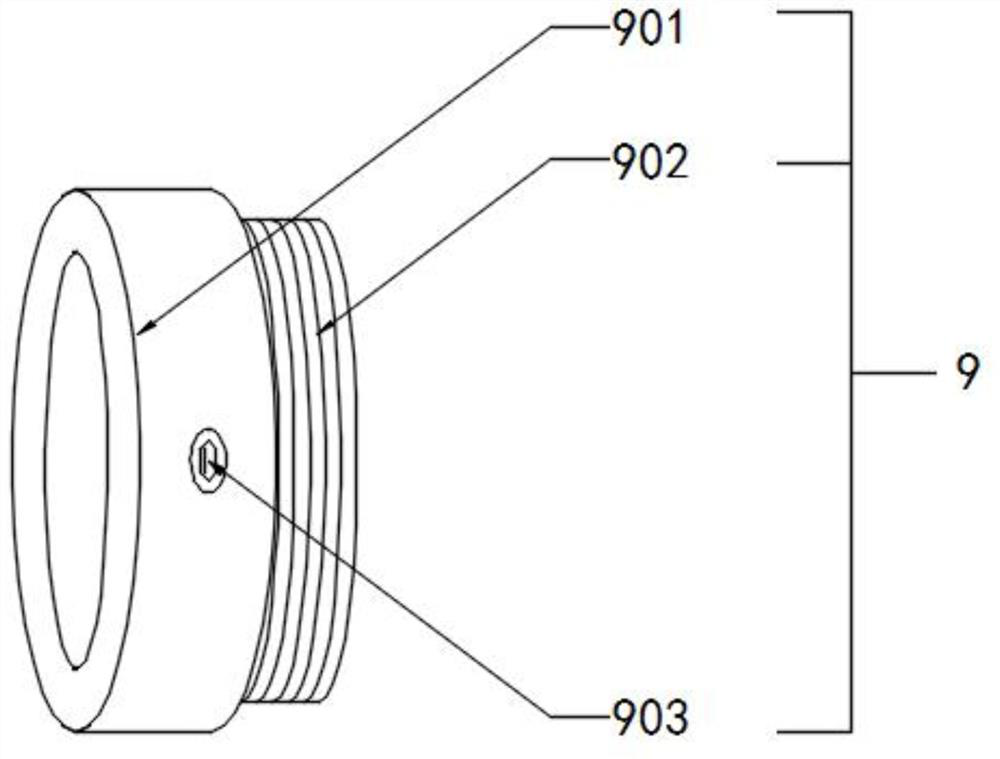

[0030] Working principle: the known flange is a connecting member for the end of the pipeline 11. The fixed connection between the first flange piece 1 and the second flange piece 2 makes the pipeline 11 sealed. When in use, the fixed ring 3 and the pressurized The mechanism 9 is sleeved on the pipeline 11. After the threaded cylinder 902 and the fixing ring 3 are fixed by spot welding, the sleeve 901 is adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com