Steel bar truss keel standard formwork cast-in-place light concrete partition wall construction method

A reinforced truss, light concrete technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of many installation procedures, high cost, low work efficiency, etc., and achieve the effect of better quality, low cost, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

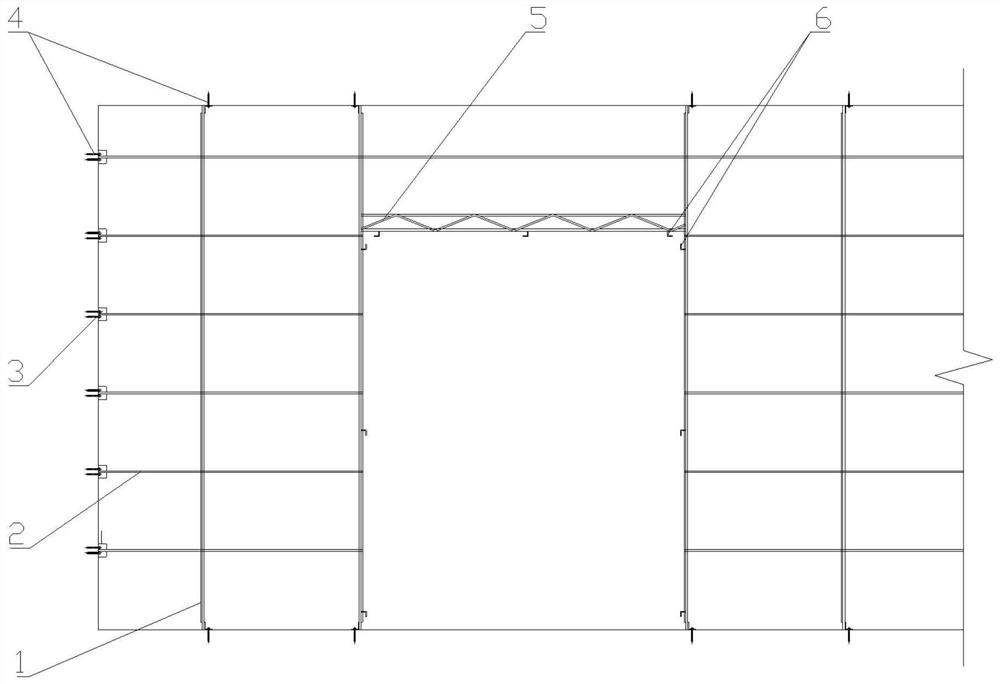

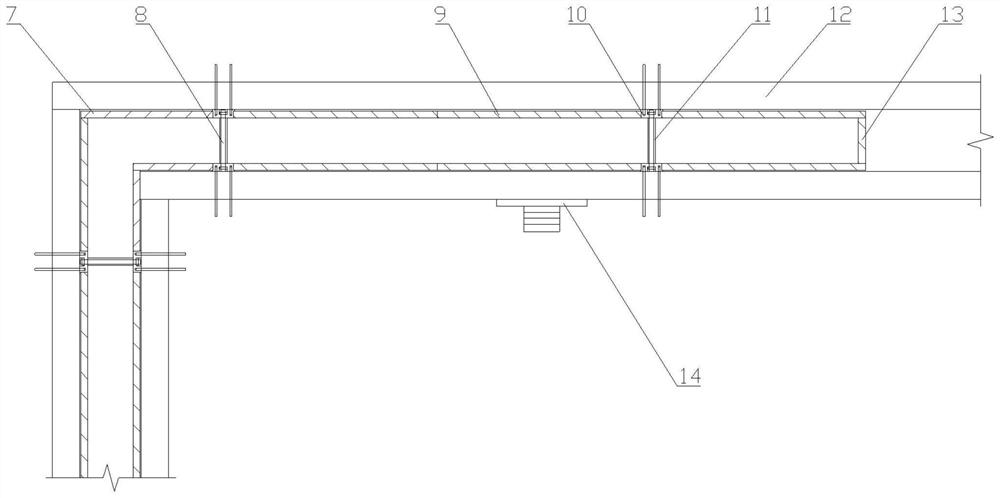

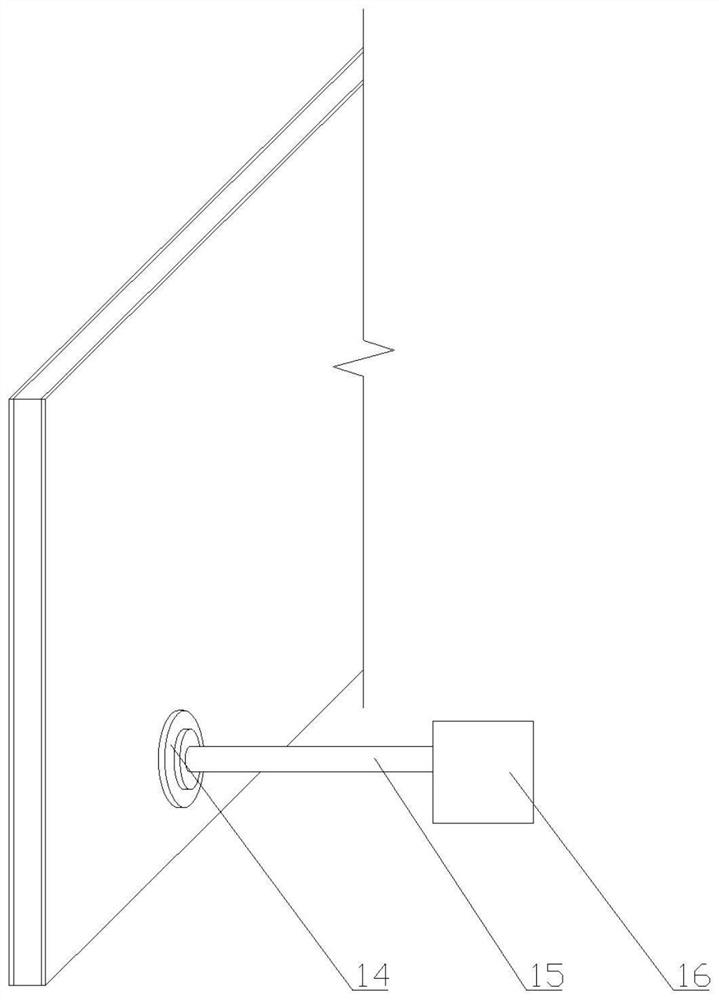

[0042] like Figure 1-3 Shown, a kind of reinforced truss keel standard cast-in-place light concrete partition wall construction method, comprises the following steps:

[0043] Step 1: Install the steel truss keel system;

[0044] Step 2: Install the quick-install formwork system on the steel truss keel system;

[0045] Step 3: Install the pouring light concrete system on the quick-install formwork system, and pour concrete into the reinforced truss keel system through the pouring light concrete system;

[0046] In step 1, the reinforced truss keel system includes a plurality of columns 1 installed in the vertical direction, and a plurality of steel braces 2 are installed between the columns, and a connection component is installed at one end of the reinforcement braces 2, and a formwork connection is also installed on the columns 1 Item 6.

[0047] Working principle: first install the steel truss keel system on the beam and slab, then install the quick-install formwork sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com