Centrifugal air compressor based on hydrogen fuel cell engine

A technology for centrifugal air compressors and motor rotors, applied to liquid fuel engines, machines/engines, electric components, etc., can solve problems such as poor stability, low speed, and high power consumption, and achieve improved stability, easy manufacturing, and The effect of saving the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

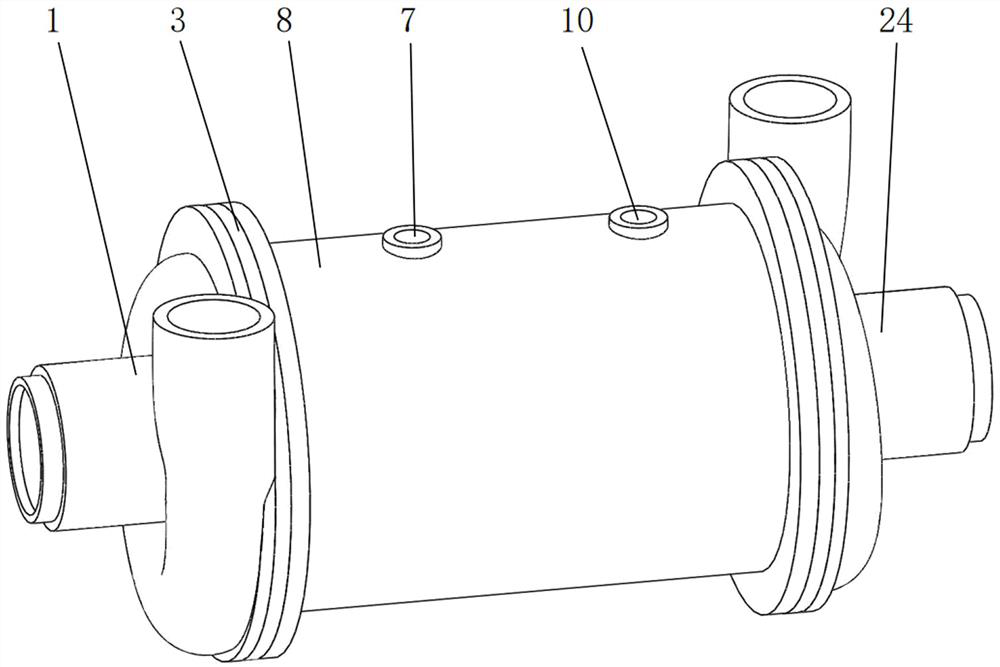

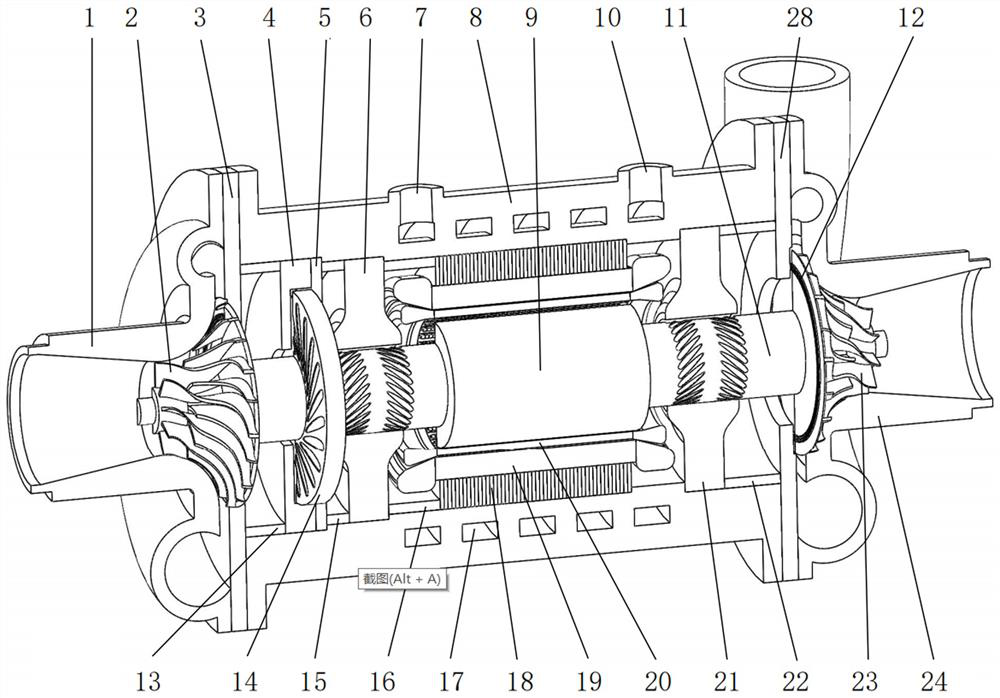

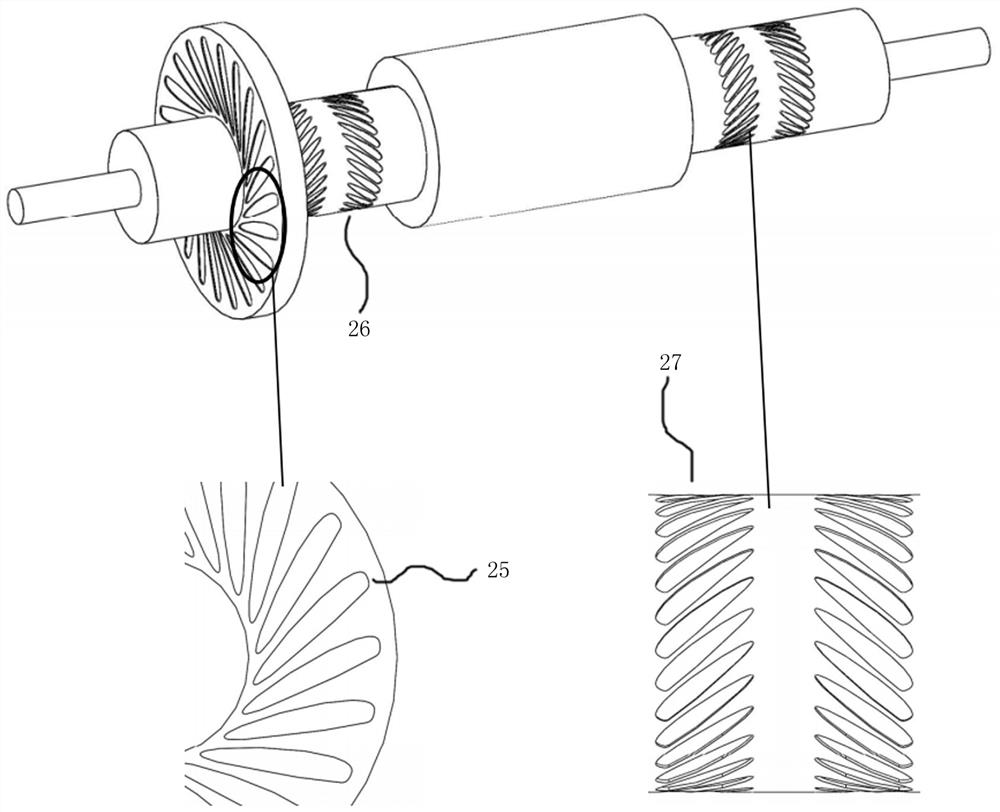

[0041] A centrifugal air compressor based on a hydrogen fuel cell engine, as shown in the accompanying drawings, includes a rotor part, a gas bearing part, and a stator part: the rotor part located in the middle of the centrifugal air compressor includes a rotor main shaft 11 and is integrated with the rotor main shaft 11 Manufactured thrust plate 14 and motor rotor 9.

[0042] The rotor main shaft 11 on both sides of the thrust plate 14 is provided with a concentric gas thrust bearing cover plate 4 and a gas thrust bearing back plate 5, the gas thrust bearing cover plate 4 is opposite to the gas thrust bearing back plate 5 The end faces are provided with circular grooves; the thrust plate 14 is located in the two circular grooves, the thickness of the thrust plate 14 is less than the sum of the depths of the two circular grooves, and the diameter of the thrust plate 14 is smaller than the depth of the two circular grooves. diameter.

[0043] The gas bearing part includes a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com