Electric forklift driving and hydraulic integrated power system and control method thereof

A technology for power systems and electric forklifts, applied in electric vehicles, fluid pressure actuation system components, control drives, etc., can solve the problems of heat dissipation efficiency and functions that are difficult to realize, the distance of motor control units, and the impact on power usage efficiency, etc., to achieve The effect of prolonging the working time of forklifts, reducing the length of cables, and reducing assembly and installation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

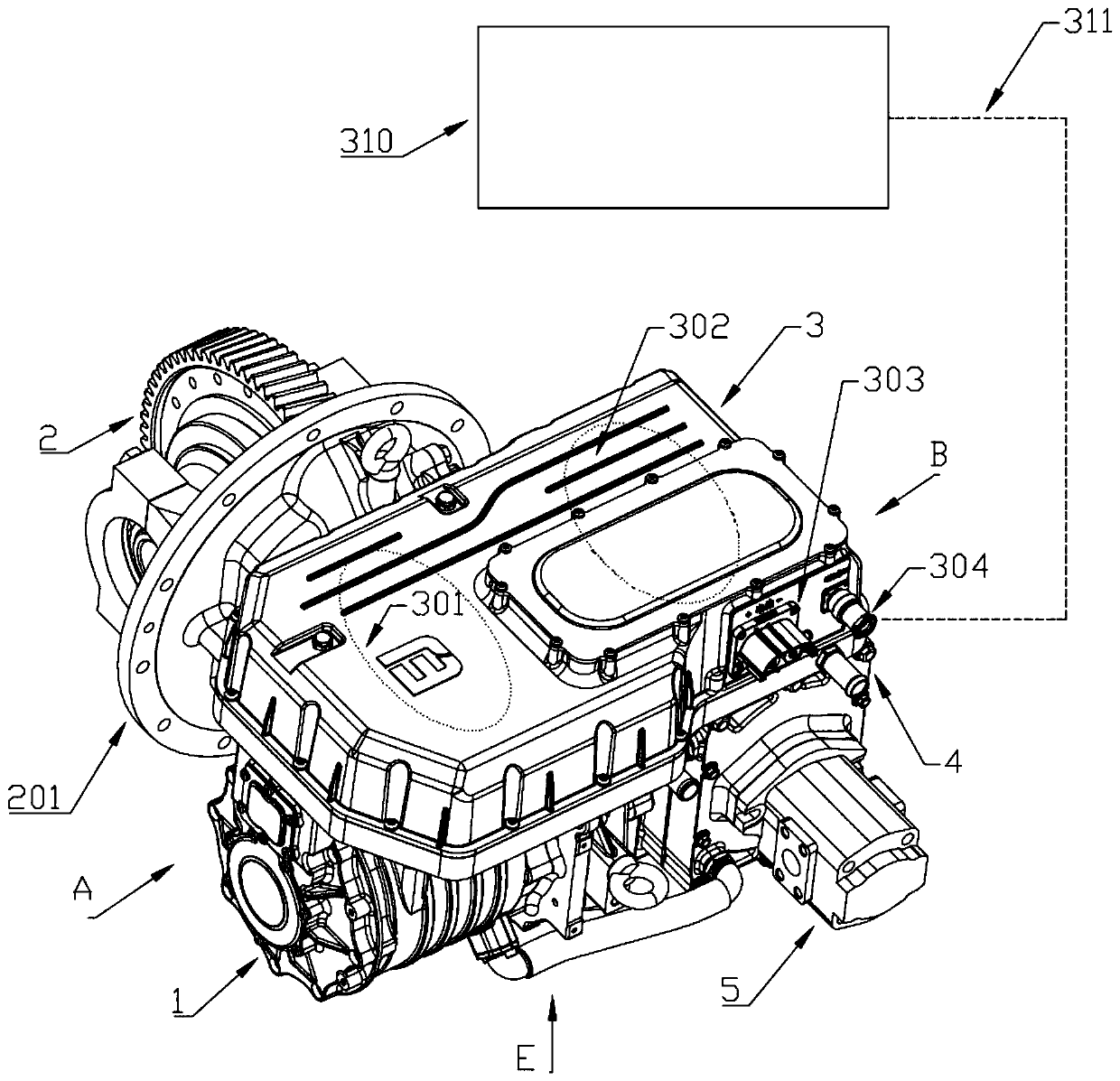

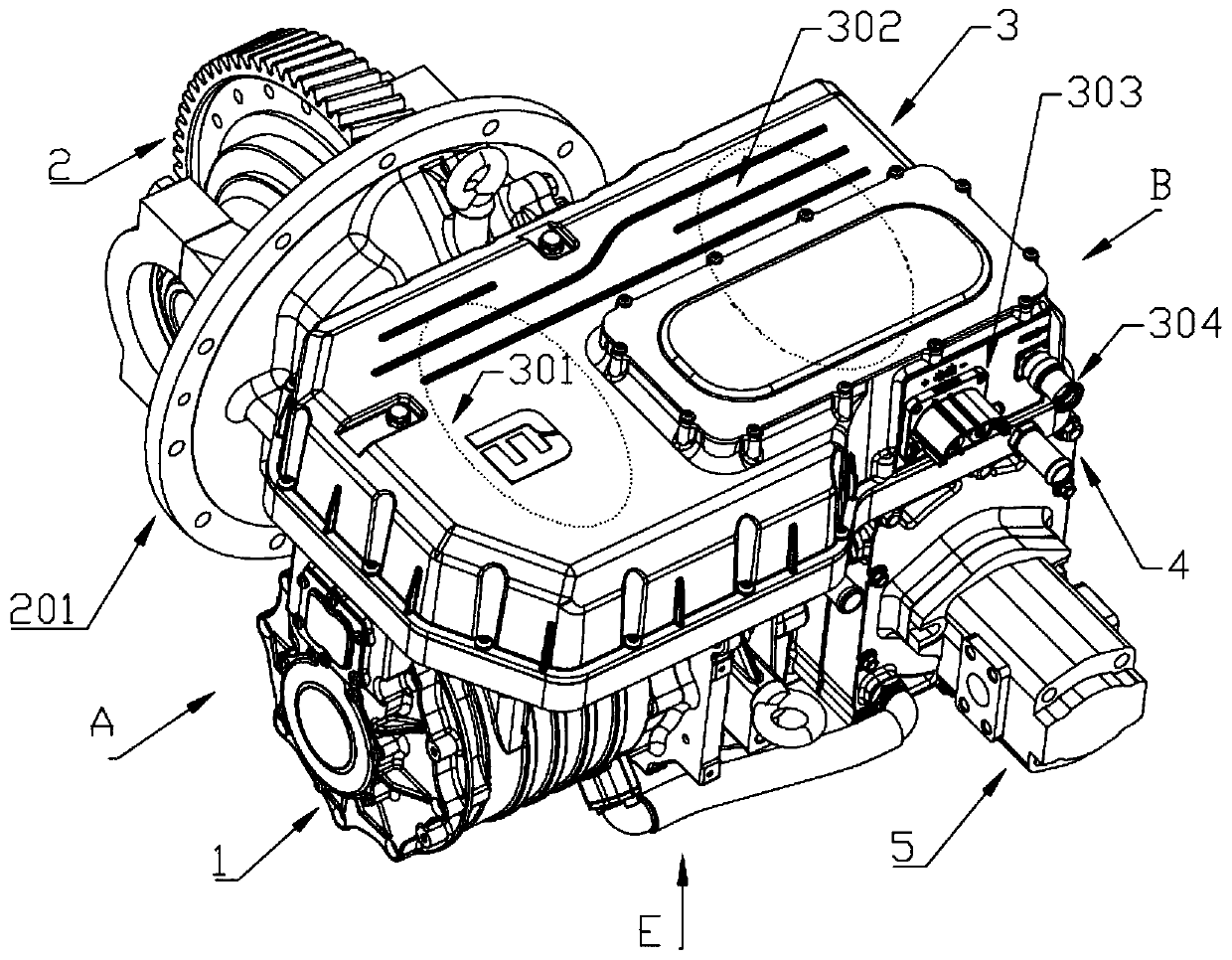

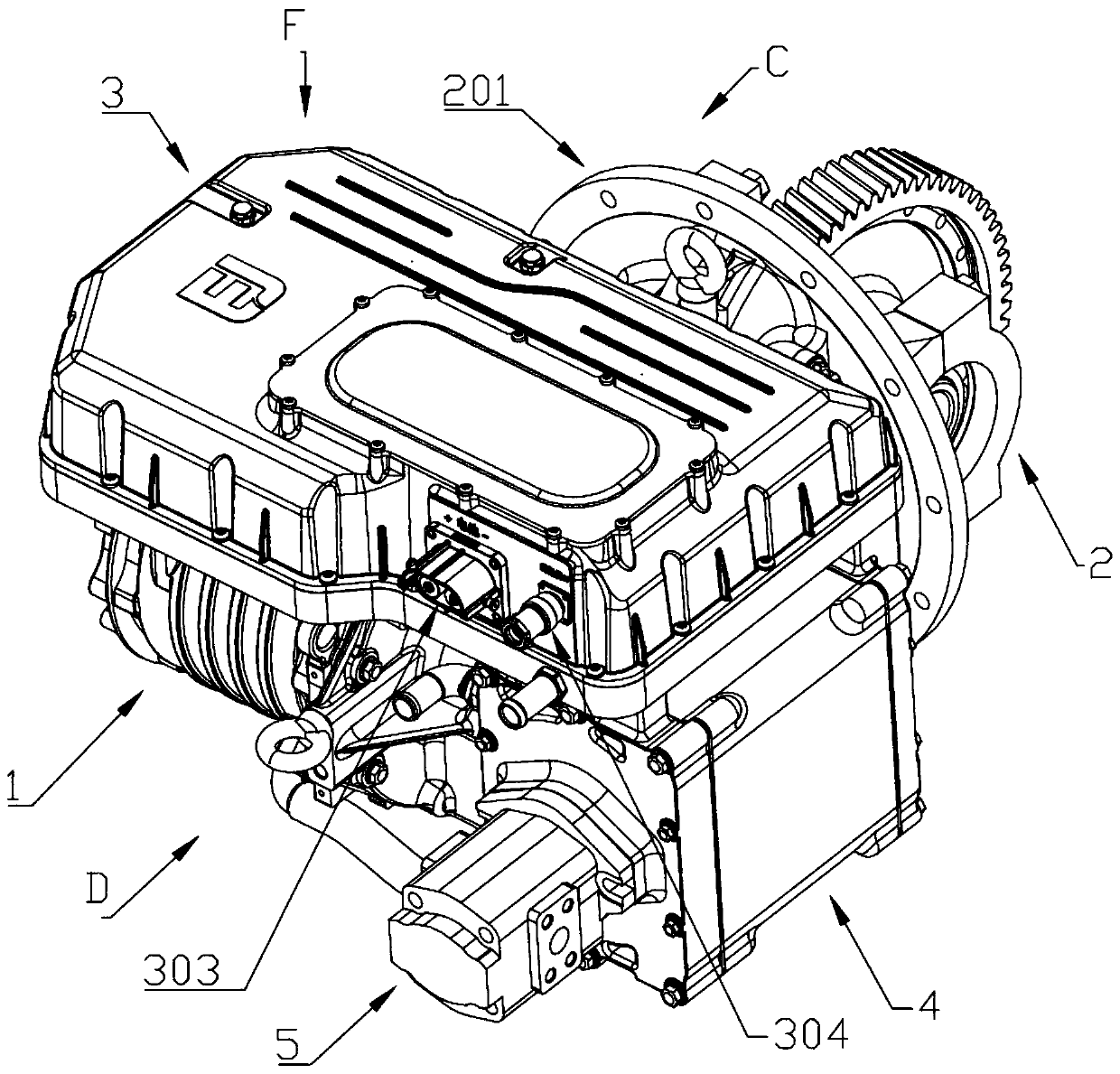

[0037] Such as Figure 1-9 As shown, an electric forklift driving and hydraulic integrated power system and its control method include a driving power subsystem, a hydraulic power subsystem and an upper power control subsystem;

[0038] Wherein, the driving power subsystem includes a driving motor 1, a parallel shaft reducer 2 and a driving motor control unit 301; the output shaft of the driving motor 1 is coaxially connected with the input shaft of the parallel shaft reducer 2 through a spline; the Parallel shaft reducer 2 includes several groups of gear shafts arranged in parallel. Each pair of paired gear sets on the gear shafts meshes with each other, and a differential is provided on the output gear shaft of the last stage, and all gear shafts are set on the reduction gear through bearings. on the housing; the driving motor control unit 301 is arranged inside the two-in-one motor controller 3 of the driving motor and the oil pump motor;

[0039] The hydraulic power subsy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com